New cartoner improves operation

March 11, 2015

Taking a bag of cereal out of its box in an attempt to find the prize at the bottom is easy. Getting the bag back into the box can also prove simple enough–if you have no particular concern about speed or accuracy. However, if you are operating a packaging line and need to quickly and accurately insert thousands of bags into boxes of varying sizes with little to no downtime, the task becomes much more complex. Manufacturers rely on packaging machines to meet this need and to ensure that every product makes its way into a box without damaging the contents.

California Cereal Products, Inc., Oakland, CA, needed a new cartoner in its existing packaging line to keep up with its processing operations. "We were looking for a cartoner that would out-produce our process line, and it had to be flexible enough to run a variety of different packages, including being able to put two bags in a box," says president Mark Graham. "Size was also critical, because it had to have a small enough footprint to fit into existing space on our packaging line."

California Cereal Products, Inc., Oakland, CA, needed a new cartoner in its existing packaging line to keep up with its processing operations. "We were looking for a cartoner that would out-produce our process line, and it had to be flexible enough to run a variety of different packages, including being able to put two bags in a box," says president Mark Graham. "Size was also critical, because it had to have a small enough footprint to fit into existing space on our packaging line."

California Cereal Products produces traditional batch-cooked crisp rice, corn flakes and sugar-coated variations, and contract-packages them in retail and bulk packages. The new cartoner is installed on a line running 10.8-oz packages of a premium product for a major cereal company.

California Cereal Products began talking to Triangle about a year ago and purchased a Triangle/FlexCell cartoner before PACK EXPO 2002. "They wanted to exhibit the machine at PACK EXPO, so we took delivery after the show, and started running it around the first of this year," says Graham.

The Triangle/FlexCell was designed to meet customer requirements for a bag-in-box cartoner that could run 90 to 100 cartons/min with minimal changeover time and a small footprint. Previously, customers requiring this line speed were forced to purchase large, continuous-motion cartoners that operate at speeds up to 250 cartons/min.

However, meeting the lower-speed design requirements with these cartoners would be excessive in both price and floor space. On the other hand, intermittent-motion cartoners that meet the lower floor-space requirements top out at 50 to 60 cartons/min. To fill this gap, Triangle worked with Rockwell Automation to create its Triangle/FlexCell cartoner, which features a completely different way of advancing cartons and loading bags into the cartons.

The Triangle/FlexCell uses Rockwell Automation's Integrated Architecture, which includes exclusive features such as an integrated platform for motion and machine control, a single programming environment and advanced networking services. As a result of this new approach, Triangle was able to deliver to its customers a cartoner with superior efficiency and versatility, including the following benefits:

• Floor space: Decreased machine size from 240 sq ft to 50 sq ft.

• Product changeover: Reduced changeover from two to four hours to just 10 min.

• Maintenance costs: Reduced the number of moving parts and wear items by 70 percent.

• Delivery cycle: Shortened time-to-market from six months to three months.

Starting fresh

Horizontal cartoners are traditionally large, expensive machines that are not well suited for frequent line changes. In addition to devouring costly floor space, these cartoners force manufactures to shut down production lines for long periods of time to change from one product to another.

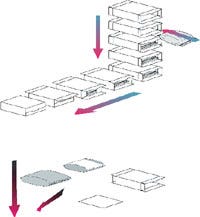

To combat these challenges, Triangle's first goal was to decrease the size of the machine. Triangle far exceeded the goal by designing a machine with the smallest footprint available for its speed range. With the Triangle/FlexCell having a mere 50-sq-ft footprint, traditional equipment was comparatively four times larger. Triangle accomplished this feat by making part of the carton handling and indexing portion of the machine vertical. And, rather than moving in a strictly horizontal fashion, flat cartons are elevated, set up and indexed downward. Furthermore, the machine indexes on the short dimension of the carton, which increases the cycle rate and time for loading, as well as decreases the machine length. The compact 5 x 10-ft machine footprint opened up valuable floor space for Triangle's customers.

Delivering maximum machine flexibility was also a goal of the new design. End users often have to make frequent size changes, yet still deliver customer orders "just in time." As many solutions require prohibitive changeover times and costly changeparts, Triangle sought a solution made possible by Rockwell Automation automated controls.

Traditional cartoners are mechanically driven machines equipped with a main drive shaft, multiple gearboxes and numerous timing chains. With its new design, Triangle wanted an alternate mechanical drive source that could not only fit in a small space, but also accommodate fast product changeovers. That led them to the idea of using a virtual drive train and integrated control technology. The result is a new multidrive motion solution that not only synchronizes, but also simplifies the operation.

An integrated platform for motion and machine control

Instead of using gearboxes and shafts to transport the carton through the machine, Triangle engineers significantly enhanced machine flexibility by employing a Rockwell Automation Kinetix Integrated Motion solution featuring an Allen-Bradley ControlLogix™ controller, Ultra3000 digital servo drives and MP-Series servo motors. Other solutions require a dedicated controller for sequential and I/O control, and another controller for motion control, each with its own software package, hardwiring, communications and synchronization logic.

The ControlLogix-based solution, which includes eight servo axes and a noise-immune, fiberoptic SERCOS (SErial Realtime COmmunication System) interface, eliminates multiple application programs and other redundancies, by providing a single, integrated system that simplifies the system architecture and streamlines the machine development process. With this solution, the Triangle/FlexCell can easily manage product changeovers. Triangle's customers only need to enter the parameters once, using a touchscreen PanelView™ for the HMI interface.

Another advantage of an integrated motion control and I/O platform is a single programming environment. This eliminates programming and synchronizing two separate controllers for every machine function. In addition, the Rockwell Software RSLogix 5000™ programming software features technology such as symbolic addressing and a common-tag database, which further decrease engineering time.

"In previous designs, we would have been required to program every device sequentially rather than simultaneously, increasing our engineering costs and extending our time-to-market," says Steve Bergholt, chief engineer at Triangle. "Symbolic addresses lay a foundation for concurrent engineering, as they provide the opportunity for our programmers to work in parallel on the electrical design and application code. These same programming benefits help us respond quickly by making programming alterations to accommodate customer requests."

|

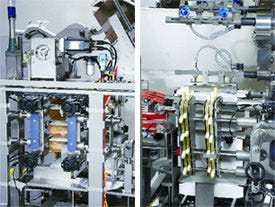

Integrated digital servo motion control eliminates programming and synchronizing two separate controllers for every machine function. Intermittent motion indexes cartons downward, left. |

Designed for industrial applications, DeviceNet™ and EtherNet/IP™ networks provide a common set of services, enabling users to exchange data for fast and precise control, configure systems and devices, and collect data for trending or analysis. Equipping the Triangle/FlexCell with a DeviceNet network enables Triangle to pull information from any point in the control system without expensive hardware bridges or programming fixes. Triangle uses the network in tandem with EtherNet/IP to allow a manufacturer to control all of its cartoners through one operator interface. This allows, for example, the packaging department to communicate with the batch process that's making the cereal and the shipping department that's waiting for cartons. The plant is no longer comprised of isolated cells of activity.

In control

Using Allen-Bradley 160 variable-speed drives on DeviceNet, Triangle/FlexCell conveyors control the spacing between the bags. In addition to turning the drives on and off, using DeviceNet simplifies wiring and allows for drive information to be transferred back to the controller.

As bags travel along the conveyors to the cartoner, Allen-Bradley Rightsight photoeyes confirm whether or not the bags are in the proper position. Incorrectly positioned bags are tracked with motion control and rejected. This ensures that everything is on track for the next step.

Flat cartons are pulled out of the magazine by a servo-drive-controlled rotary arm that opens the carton into carrier lugs. Carrier lugs hold the box open at its four edges, keeping it open and square for bag insertion and downward indexing by four servo motors. After bag loading, the carton is transferred from the vertical section into the horizontal transport. This section of the machine folds and glues the carton flaps. Carton setup in the lugs needs to be precise to ensure optimum speed and performance. ControlLogix's ability to tightly integrate motion functions with the high speed of the SERCOS communication, allows the eight servo axes to deliver optimum synchronization.

"In the past it was necessary to make one move match another to keep everything consistent," says Bergholt. "The Rockwell Automation integrated-motion technology produces a dual benefit. First it allows us to redefine the relationship between the axes during changeover so that all the relationships are maintained for the next operation. Second, a single recipe selection is used to reconfigure the cartoner."

An Allen-Bradley PanelView1000™ color touchscreen operator interface mounted on a swing arm allows the user to configure and monitor the entire operation of the Triangle/FlexCell. The PanelView interface allows users to receive messages via Ethernet from the ControlLogix controller or drives. Triangle also included additional ports on the local Ethernet switch to plug into a plant-wide network. This allows the customer to link the cartoner to their overall system, bridging information from the packaging floor to the office.

"A large part of our success is a commitment to using flexible, off-the-shelf automation technology that performs like custom equipment designed for our customer's unique applications," adds Bergholt.

Passing along the benefits

Manufacturers have long struggled with quickly switching carton sizes or pack patterns, such as changing from a single- to a double-pack carton. When it comes to changeover times, a typical carton size change on older-style equipment can take from two to four hours. By using the Triangle/FlexCell with Rockwell Automation's Integrated Architecture, the manufacturer can change from one size or pack pattern to the next in 10 to 20 minutes. The PanelView operator interface displays various machine settings. Users simply indicate the carton size, the servo drives adjust accordingly, and the machine is ready to run the new size.

Reduced maintenance costs are another feature of the system. Being able to troubleshoot problems quickly and efficiently is a powerful advantage for manufacturers because it shortens downtime. The integrated control and communications technology, which notifies users of operational changes such as an unusual increase in power consumption, allows them to predict and schedule when something needs to be replaced. This significantly reduces the risk of unscheduled downtime.

Reduced maintenance costs are another feature of the system. Being able to troubleshoot problems quickly and efficiently is a powerful advantage for manufacturers because it shortens downtime. The integrated control and communications technology, which notifies users of operational changes such as an unusual increase in power consumption, allows them to predict and schedule when something needs to be replaced. This significantly reduces the risk of unscheduled downtime.

Smart servo drives save time. In the past, engineers had to configure the drive and motor by connecting a laptop to the drive. "Now, all a customer needs to do is set the switch to the address and plug in the SERCOS fiberoptic cable to bring a machine back online," says Bergholt. This saves commissioning time upon startup, ensures proper drive replacement and gives users real-time reporting of critical motor data, such as temperature.

Machine delivery times are also reduced. With servo control, mechanical adjustments can be made with a simple keyboard entry. The machine design is adjustable and flexible, as mechanical parts no longer have to be designed for each cartoner and carton size changes. "The flexible architecture allows us to reuse the design and simplify engineering tasks. We can forecast and prebuild the Triangle/FlexCell, allocating our resources to get a machine to market in three months instead of six months, and save thousands of dollars in engineering costs," adds Bergholt.

"The machine has worked very well for us, and Triangle has been very responsive to our servicing needs," says California Cereal Products' president, Graham. "When we were ready to start running the cartoner, Triangle personnel came out one day, and the machine was running the next day."

More information is available:

Cartoner: Triangle Packaging Machinery Co., 773/889-0200. Circle No. 218.

Integrated Architecture: Rockwell Automation, 630/654-6839. Circle No. 219.

About the Author(s)

You May Also Like