10 new machines answer food packaging demands

September 22, 2019

Hygienic designs, robotic automation and improved inspection are among the key attributes of packaging systems engineered for demanding food applications.

Of the more than 2,000 exhibitors at Pack Expo Las Vegas 2019 (Sept. 23-25; Las Vegas), here are 10 new packaging machines attendees who are looking for solutions to their food manufacturing needs can see in person.

1. Rotary pouch unit fills and seals pre-formed bags (see photo at top of page)

The Triangle/JDD Rotary Pouch Machine is designed to fill and seal Doyen bags, three-sided seal, flat and standup pouches, and zippered bags. From Triangle Package Machinery, the system reportedly fills at speeds of up to 50 pouches per minute.

The rotary pouch filler is suitable for granola, snacks, candy, popcorn, dried fruit, nuts, baking mixes and other edible products. The machine automatically stops to fill, and unopened bags won’t be filled, reducing product waste. Also, the no-fill/no-seal feature enables unopened bags to be reused.

Two models are available. The JRPM-8812 handles bag widths from 4 to 8 inches wide and heights of 4 to 12 inches, while the JRPM-81215 accepts pouches from 6.5 to 12 inches wide and 8 to 15 inches high.

Users can add a number of options to the rotary pouch filler to enhance performance and functionality. These include nitrogen gas flush, staging gate, statistics backup on flash-card Ethernet, and turnkey integration.

Triangle Package Machinery will show the JDD Rotary Pouch Machine at Pack Expo Las Vegas 2019 in Booth C-2614.

2. Cartoning machine combines high speed with vision features

The Peregrine cartoning system incorporates advanced vision technology in a high-speed system. The technology from JLS is suited for packing flexible bags, flow-wrapped packs and other primary packaging into cartons, including tri-seal.

The system is designed to cut down on changeover time and meet the production needs for small batches. It is suitable for a number of food applications, including baked goods, snacks, candy, frozen and prepared foods, protein items and ice cream treats.

JLS Automation will show the Peregrine at Pack Expo Las Vegas 2019 in Booth LS-6135.

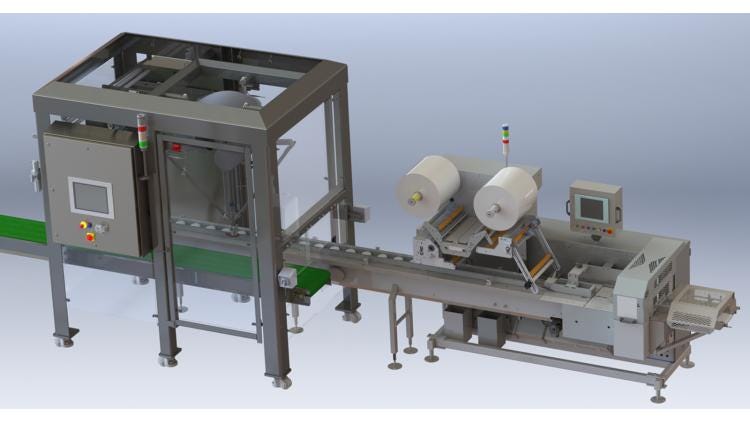

3. Flow wrapper includes hygienic stainless-steel conveyor

The Revolution flow wrapper features a stainless-steel infeed conveyor. The servo-driven, welded conveyor on Campbell Wrapper’s new system eliminates harborage areas for easy, effective sanitation and allergen cleanup.

Features include the Hygienic JLS Talon vision-guided robotic pick-and-place system. With an IP69K stainless-steel Delta robot, it can pick from a random presentation on a belt, then load products directly into the infeed at more than 100 picks per minute. The system can load and overwrap various bakery and frozen food items, including soft cakes, cookies, snack bars, corn dogs, burritos and breakfast sandwiches.

Campbell Wrapper will show the Revolution flow wrapper with a JLS Automation robotic loading system at Pack Expo Las Vegas 2019 in Booth C-2629.

4. Tray sealer creates hermetic MAP paperboard packaging

Proseal is demonstrating production of the Halopack tray—the first fully hermetic paperboard modified-atmosphere packaging (MAP)—on its SKR tray sealing machine. The board comprises more than 90% recycled material, and the trays incorporate high-barrier properties designed to preserve food quality and extend shelf life.

The Halopack trays are intended to deliver appealing product presentation, a high level of environmental performance, reduced food waste, long shelf life and ease of recycling in a MAP package. A peelable inner layer can be peeled off the tray after use, so that the tray can be recycled.

Proseal will show the Halopack tray production and SKR tray sealer at Pack Expo Las Vegas 2019 in Booth LS-6563.

The Halopack tray

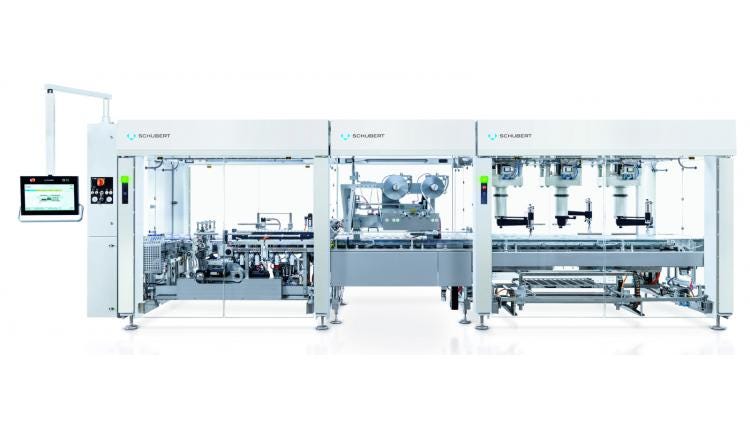

5. Flowpack system gently packages heat-sensitive products

The lightline Flowpacker combines a Flowpacker flowpacking unit and Pickerline pick-and-place machine in an integrated unit. The system, produced by Schubert, includes advanced sealing technology for gently packing heat-sensitive products into flowpacks.

The Pickerline technology enables manufacturers to handle standardized packaging tasks with a combination of high efficiency, quality and cost effectiveness. F4 robots pick products from the belt and place them in trays; users can choose configurations of one to six robots to fit their specific performance requirements.

The company’s Flowpacker is suitable for flow wrapping different product formats, whether they are flat or laying on their side, stacked or pre-packed. Integrated 3Dimage recognition detects position, location, height and quality, ensuring robots only pick products with no flaws. Customers can choose from a number of sealing systems, including an advanced ultrasonic sealing unit.

Schubert will show the lightline Flowpacker at Pack Expo Las Vegas 2019 in Booth US-7649.

![]()

6. Leak detection unit handles large-format packages

The Contura S600 non-destructive leak detection system is engineered to provide reliable, cost-effective testing of bulk retail and foodservice packaging, modified-atmosphere packs and flexible containers. The technology of the Inficon machine offers manufacturers extended shelf life, ability to avoid expensive recalls, and reduction of product waste.

The latest model in the company’s line of non-destructive leak detection equipment uses a proprietary differential pressure method to detect both gross and fine leaks, with faster, easier and more quantifiable performance than other methodologies. It is suitable for pet foods, meat and poultry, baked goods, candy and snacks, cheeses, grains, cereal and more.

Inficon will show the Contura S600 at Pack Expo Las Vegas 2019 in Booth US-7777.

7. Hygienic portion-pack machine improves cup handling

A new frame and guarding package on the P300 portion-pack form-fill-sealer improve accessibility of the hygienic low-acid aseptic system from IMA’s Hassia division. Additionally, a new cell board conveyor discharge controls round cups through case packing.

Producing from about 350 to 900 cups per minute, the P300 can process various cup shapes—round and rectangular—with a variety of foods, such as butter, cream cheese, soft cheese, condiments, sauces, jams, honey, spreads and dressings.

IMA/Hassia will show the P500 at Pack Expo Las Vegas 2019 in Booth C-3200.

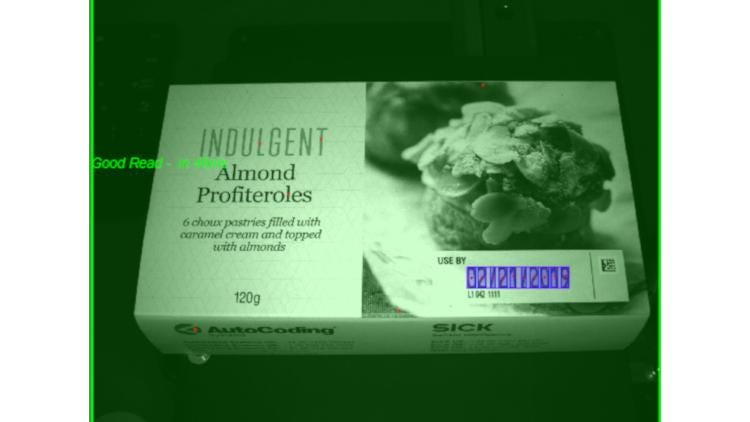

8. Automatic print inspection technology shows signs of intelligence

The 4Sight automatic print inspection system is designed to communicate with any brand of printer, with no need to program the camera what to watch out for. The intelligent inspection system is the result of a partnership between AutoCoding Systems and SICK.

While traditional vision inspection typically requires fixturing with an edge or logo, the 4Sight software copes automatically with variations in artwork, background and text locations. Its versatility enables users to handle varying levels of inspection ranging from print presence to full optical character recognition (OCR). Operators have the freedom to set acceptable print quality tolerances to define good, bad or no read on a per-product basis.

Processing occurs on board within the SICK camera, with no line-side PC required. Setup of the camera position, focus and illumination is simple, with no need for operators to configure features or regions of interest. Software automatically adjusts to accommodate real-time message changes. Several configurable features allow for simple optimization of fast processing time, making the system suitable for bottling, canning lines and other high-speed beverage solutions.

AutoCoding Systems will show 4Sight at Pack Expo Las Vegas 2019 in the SICK Booth LS-6419.

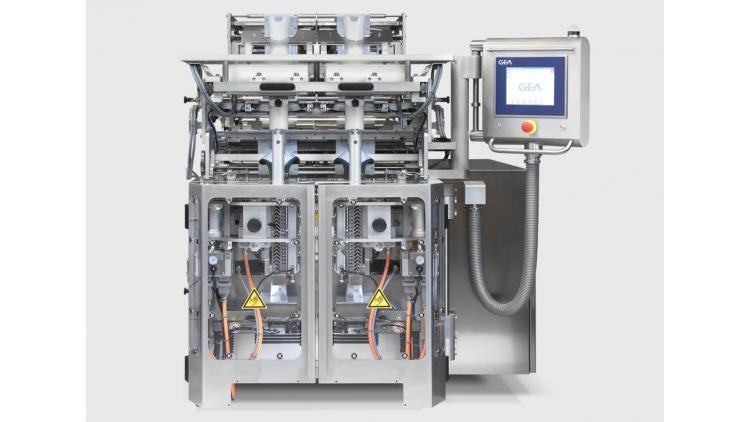

9. Vertical packaging machine offers high speeds, low cost

The SmartPacker Twin Tube packing system offers a reinforced modular design and combined production output of up to 500 bags per minute. The new packaging machine from GEA is designed to bring about productivity, flexibility and operational efficiency.

Two parallel forming tubes run from a single drive, a design that achieves up to four times the speed of conventional baggers. It forms pillow bags suited for hard or soft candy, savory snacks, nuts, small cookies, dried fruit and similar products. Monitored film transport and jaw movement facilitate consistent, accurate bag length.

The machine offers a high degree of efficiency in a relatively small footprint, and its modular design enables simple addition of options or upgrades. The fully integrated TiroLabel unit allows for labeling precision, and automatic web tracking eliminates film deviations during production with no need for manual adjustment. A Jumbo Roll option accepts film reels up to 100 kg for longer runs.

GEA will show the Smart Packer TwinTube at Pack Expo Las Vegas 2019 in Booth LS-5905.

10. X-ray machine promises big performance in small package

The Eagle Pack 240HC is a compact x-ray system designed for easy use and cleaning in meat, poultry, dairy and other food packaging applications where daily sanitation is required.

The compact machine, available from Eagle Product Inspection, can inspect a large number of package types, such as chubs, overwrapped trays, pouches, cartons, tubs, cups and plastic containers. The technology can detect and reject glass, metal, stones and rocks, some plastic and rubber compounds, calcified bones and other foreign bodies.

The x-ray unit comes with SimulTask Pro, advanced inspection software that can manage different quality control checks simultaneously. These include mass measurement with filler feedback, component count, identification of broken or misshaped items, detection of missing clips and monitoring for unwanted voids.

Eagle Product Inspection will show Eagle Pack 240HC at Pack Expo Las Vegas 2019 in Booth C-1506.

About the Author(s)

You May Also Like