Food packaging: New packaging line for Jelly Belly Candy

pdx1004jellybelly10

A new $2-million packaging line that incorporates two vertical form/fill/seal machines and a robotic carton packer at the giant Jelly Belly Candy Co. plant in Fairfield, CA, has cut labor costs by 75 percent and reduced changeover times dramatically compared to other lines in the plant. “This line, which requires only two people, does the work of three of our other lines, each of which has two or three workers,” says director of global engineering Jim Schneider.To see the interactive version of this story, sponsored by Bosch Packaging Technology, click here.

Founded in 1898 as the Goelitz Confectionery Co., the company, in 1976, began making a new type of product, a gourmet jelly bean, appropriately named Jelly Belly, and this became a runaway favorite. The company changed its name to Jelly Belly Candy Co. in 2001.

It now produces 50 official flavors of Jelly Belly beans, which it packages both in single flavors and a mind-boggling array of mixtures in an equally mind-boggling array of package types and sizes. In total, the company produces more than 1,500 SKUs. Jelly Belly currently has factories in Fairfield, North Chicago, IL, and Thailand.

Probably the most famous proponent of Jelly Belly beans was U.S. President Ronald Reagan, who kept a jar of them on his desk in the White House and on Air Force One. He also made them the first jelly

pdx1004jellybelly1

beans in outer space, sending them on the 1983 Challenger shuttle as a surprise for the astronauts. President Reagan was responsible for one of the most popular Jelly Belly flavors, when he asked the company to produce blueberry-flavored beans so he could have a red, white and blue mixture at his inauguration.Started looking in 2008

“We began looking into a new high-speed, automated line in April 2008,” says Schneider. “We have 16 packaging lines in the plant, but we make so many changeovers to run all of our products, that they are all relatively slow and labor intensive. We wanted an efficient line that we would use for much longer runs.

“We had some Bosch Packaging Technology Inc. equipment in the plant that was working out very well for us, so when company owner and chairman of the board Herman Rowland Sr. saw a complete bag line using robots to pack cartons in the Bosch booth at the 2008 Interpack show, that pretty well cemented the decision.”

Bosch took on the project as systems integrator, and first installed the entire line at its plant in Wisconsin to ensure that it was operating properly. Jelly Belly personnel went there for the factory acceptance tests. “The line had to be

pdx1004jellybelly11

actually producing product by the end of 2008 for tax reasons,” says Schneider. “So a key requirement of the contract was that they had to deliver the equipment by Nov. 15, or we could refuse delivery. That was a real challenge, because nothing goes perfectly and things change on a project of this size, but they actually beat that deadline.”Local contractors installed the equipment, and Bosch personnel spent two weeks at the plant getting everything running. “We started the line before Christmas, and it has been running ever since,” says Schneider.

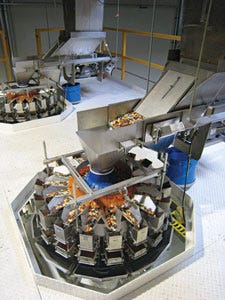

Rotary scales have 18 weigh heads

The new line, which produces about 60 SKUs, incorporates two Bosch model SVE2510 vertical form/fill/seal machines installed beside each other—each running 120 bags/min. Both machines run the same product simultaneously, and the discharge from the two machines is combined onto a common conveyor.

Each bagger has a Yamato Corp. radial weighing system mounted on a platform above it. Jelly Belly beans are transported to the packaging line in plastic tote bins or in plastic cases.

The plastic bins discharge through a bottom gate into a vibrating pan that feeds them into a bucket elevator system that lifts them to the scale platform. Workers dump the plastic trays onto a stoker belt located opposite the bins, and it also discharges into the bucket elevator. This entire product feeding system was supplied by Frazier & Son.

The elevator travels above both scale systems and discharges the beans as needed. In an unusual operation, the elevator runs continuously rather than stop when the scale hoppers are filled. A sensor in the bucket loading station senses which buckets are empty and triggers the vibrating feeder to fill only those buckets, while not discharging into buckets that are full.

pdx1004jellybelly_bty2

The Yamato weighing system above each bag machine comprises 18 individual weigh heads mounted around a vibrating top cone and associated radial feed pans. Each head of the scale consists of a feed bucket and a weigh bucket.Incoming product discharges from the customer's infeed conveyor onto the vibrating top cone. From there it is dispersed evenly into the 18 radial feeders. The radial feeders vibrate at a set amplitude and time causing the product to flow from the top cone to the feed bucket.

The amount of amplitude and time is established to put a set amount of product into each feed bucket. The feed buckets, in turn, control the product flow into the weigh buckets. The ideal amount of product delivered to each weigh bucket is about one-third to one-sixth of the weight of the finished package.

For each weighment (product bag weight), the Yamatocontrol system evaluates the weights in all of the available weigh buckets. The system identifies the best combination of weigh buckets that come closest to containing the total bag weight without being underweight. The selected weigh buckets then are activated to discharge to the bagger.

Pdx1004_jellybelly_line

The Yamato Frontier scales are unique to the industry in that each weigh bucket has two doors that open to inner and outer funnels that discharge into collection buckets at the bottom of the scale. The product is discharged from this point into the bagger. For this system, the Frontier scale utilizes a three collection-bucket system that discharges the product charge alternately into the bagger.Thus, each set of collection buckets is actually running at half the speed of the bagger. The dual funnels and collection bucket features found on the Yamato Frontier scales are required for the Jelly Belly operation because of the high speed operation of the bagging machine. Slower packaging operations typically operate with weigh buckets that discharge directly into the bagging machine.

Each product discharge (weighment) is displayed on the scale's computer monitor, showing the fill weight, speed, which buckets released product and statistical data. The weighing system automatically calibrates itself for bulk product as it passes through the system, tracks the product and continuously compensates and updates itself for optimal sensitivity.

Product from the scales passes through a metal detector from Mettler Toledo Safeline that is mounted just below the scale platform and above the bagger.

The unit automatically calibrates itself as product passes through the system, tracks the candies and continuously compensates and updates itself for optimal sensitivity.

“This was one of the items that changed during the course of the project,” says Schneider. “We had originally planned to put the metal detectors after the bagging machines, but then our marketing people decided that they wanted to use metalized film, so we put it between the scales and the baggers.”

pdx1004jellybelly8

Two vf/f/s machines

pdx1004jellybelly8

The film for the bags is supplied by Innovative Packaging Solutions Inc. The film is OPP that is printed on a nine-color rotogravure press.

The film is mounted on the back of the continuous-motion bagger and is pulled into the machine by a combination of rollers and dancer arms on the back of the machine and vacuum belts on the front of the machine. A powered roller running on top of the roll of film provides tension and maintains equilibrium as the film is pulled into the machine.

The film travels over a roller down the front of the unit, where it passes around a forming tube, and a heated shoe produces a vertical overlap seal. Two belts on opposite sides of the forming tube use a unique vacuum technology to help pull the film through the machine.

The belts, which are adjusted to be very close to the tube, but not touching it, contain slots through which a vacuum pulls the film slightly away from the tube as it travels. As described previously, the beans drop intermittently from the overhead weighing system through the forming tube into the continuously moving formed cylinder of film as it leaves this vertical forming section.

Next, the film passes through the continuous motion, servo-driven sealing jaws, which move synchronously with the film. The jaws move in against the film and induction-heat a horizontal seal across the film as they travel downwards.

They then move away from the film and reciprocate up to start the next sealing cycle. At the end of each sealing cycle, before the jaws disengage, an air-actuated blade shoots out from the center of the jaws and cuts the bag loose, after which it drops onto the takeaway conveyor.

pdx1004jellybelly7

The vf/f/s is equipped with a sensor mounted on the film carriage that detects the eyemark on the film. This sensor adjusts the speed of the vacuum belts described previously and compensates for any slight changes in the film length.This ensures that the film for each bag is always in perfect registration. This registration initiates the start of each cycle and tells the horizontal sealer and cutoff knife when to energize and the Videojet printers when to operate.

The machines are controlled by Allen-Bradley Control Logix PLCs with A-B Sercos servo-drive technology. The Allen-Bradley components are supplied by Rockwell Automation. An industrial touchscreen PC is provided for the operator interface.

The machines utilize software from Wonderware, a business unit of Invensys Systems Inc. that maintains the recipes for all of the products in memory. The operator can recall them at a touch. The software automatically sets the operating parameters, including the sealer temperatures and the servo drives that, among other things, set bag length. Additional touches to the screen display the settings currently in use, causes of operating problems and maintenance requirements.

Thermal transfer printer applies code

Two DataFlex® Plus thermal-transfer ribbon over printers from Videojet Technologies Inc. are mounted on the back of the machine just before the film enters the machine. Jelly Belly runs both preprinted and generic film. The preprinted film requires that only a date code and best-before date be printed. The generic film contains the logo, color bars and generic information, and these printers print specific information about the bag being run, such as product name, date code, use-by date, weigh and ingredient statement.

The DataFlex Plus printing system is characterized by its low-maintenance, direct ribbon drive, which minimizes downtime and delivers high availability. The long ribbon length together with the ribbon save technology minimizes the number of ribbon changes and downtime during production changeovers. The nominal ribbon loss between consecutive prints is just 0.5mm.

pdx1004jellybelly3

Jelly Belly has incorporated Videojet's CLARiNET® package-coding management software to manage the printing on all of its packaging lines at all three factories. This single-network setup and control solution for all of the printers on the line features integral bar code setup, control and pack validation.“We just scan in the bar code for whatever product we want to run, and the system automatically sets up all of the printers on the line from information stored on our central database, says Schneider. “All three of our factories pull their printing data from one location. With 1,500 SKUs it is the only way to insure what we print is accurate and up to date. This basically eliminates errors from someone entering the wrong data.”

Carton former provides positive control

Bags discharge from the bagger onto individual conveyors and then are merged onto a mass-flow belt that transports them to a Bosch Paloma robotic packer, The cartons for the bags are formed from blanks by a Bosch Cobra carton former. A key feature of this machine is its unique blank transport mechanism, which provides positive blank control from the magazine picking through hot-melt application to the forming-head placement. In this process, once a blank is in place, the glue is applied, after which the forming head descends and pushes the formed carton down onto the take-away conveyor, which delivers it to the Palomar robot.

Three pick-and-place robots

pdx1004jellybelly9

The cartons enter the Paloma, which has three Delta robots in a row, on a flow conveyor running parallel to the robots. A sensor detects the leading edge of each carton and the length of the carton. Since the controller knows the position of the carton, it can calculate the exact location of each carton as it travels through the unit. This information is transmitted to the robots, so they know exactly where to place the bags.Jelly Belly hand packs some products from the baggers, so there is a pullnose-conveyor system to divert bags to the manual operation just ahead of the robot. Otherwise, the bags discharge onto the mass-flow belt conveyor that transports the Jelly Belly bags through the Paloma robot in the opposite direction to the cartons. The Paloma is equipped with a vision system from Matrox Electronic Systems Ltd. that detects the locations of the bags on the belt and transmits that information to the robots.

The robots pick up individual bags with vacuum cups, and the robot arms place the bags into the carton in the correct orientation, pack pattern and count. In this operation, the first robot is told the location of all of the bags entering the loader.

After it picks up bags to place in the cartons, the computer removes those bags from its memory, so the second robot is told only the location of the remaining bags. Likewise for the third robot.

The Jelly Belly system incorporates Bosch's new Gemini 3.0 software for Delta style, pick-and-place robots, which allow 3D simulation of new production processes or optimization of existing products, while the machine operates, dramatically reducing installation and changeover times. The system incorporates BLOB (binary large object) technology that provides superior vision recognition which requires less calculation time and which was an important consideration in this operation.

The counter flow of the carton and bag conveyors through the case packer was a deliberate design element of the system. In this arrangement, the first robot sees all of the bags entering the unit, so if the carton that is leaving the packer is not filled, the robot is assured of having all of the bags it needs to complete the fill.

If the bag and carton conveyors were running in the same direction, the robot filling the carton as it leaves the unit might not have enough bags available on the conveyor belt.

“We originally planned on two robots, but that was stretching their capacity, so we added the third,” says Schneider. “The same thing with the vision capability. This way, we don't have to orient the bags coming into the packer.”

The PC-controlled packer runs cartons that contain from eight to 154 bags, and it can be programmed for all of these packs with the data retained in memory. The operator only needs to enter the product name to change its operation.

Case closing

The cartons from the carton loader pass over a Mettler-Toledo Hi-Speed checkweigher and then enter a Bosch Model 840e case closer. The cartons can enter at random, and are automatically timed into the gluing section, where glue is applied to the major and minor flaps by a Nordson Corp. glue applicator.

The cartons are then transported to the dual-cylinder closing section. The first cylinder pushes the carton 90 deg into the compression section, while folding down the top cover.

The second cylinder pushes the carton up into the compression section, which folds down the minor flaps. At this point all three flaps are folded and under compression. The next carton entering the compression section moves the previous carton up into the discharge section. From the case closer, cartons travel through a Mettler-Toledo Safeline case turner where some cases are rotated 180 deg for special printing, while others travel through without turning.

The cartons are then conveyed past a Model 3138 print-and-apply labeler from Label-Aire Inc. that is equipped with a Sato America, Inc. M8485e printer. Jelly Belly requires that the line must be able to pack into standard tri-seal shippers and into specialized combination store-shelf display shippers called caddies.

These cartons are a combination shipper and shelf-display all in one. The caddies require an additional UPC code and product-description label, which is applied by the Label-Aire print-and-apply labeler.

The cases are then printed with a case bar code by a Videojet Marsh Encore inkjet printer. This code is used downstream for palletizing. All of the cartons produced on this line then run to a centralized palletizing area, which palletizes all of the cartons produced on all 16 packaging lines.

System integrator for line

As mentioned previously, Bosch was the system integrator for this entire line. The system includes complete line controls with sensors to detect product shortages or backups and operating problems.

Each machine has its own on/off switch, but the conveyors and equipment are controlled so that they automatically will shut down and start up in sequence if there is a problem anywhere on the line.

All of the controls were supplied by Rockwell Automation. All of the bag and carton conveyors on this packaging line were supplied by Nercon Engineering & Manufacturing Inc.

“Bosch did a great job for us,” says Schneider. “We were on an extremely tight schedule, and they met our deadline. Another feature of the line and equipment is that it is relatively easy to use.

“We wanted to be able to do our own programming and maintenance, and we have achieved that goal. Scott Patrick, president of Bay Area Packaging, our local Bosch, Safeline and Hi-Speed distributor, was involved in the project from the beginning and was a tremendous help. He worked closely with us on this project from conception through startup.”

More information is available: |

Bosch Packaging Technology Inc., 715/243-2557. www.boschpackaging.com |

Bay Area Packaging, 925/933-8700. www.baypack.com |

Frazier & Son, 800/365-5438. www.frazierpack.net |

Innovative Packaging Solutions Inc., 951/693-5580. www.ipspack.com |

Label-Aire Inc., 714/441-0700. www.label-aire.com |

Matrox Electronic Systems Ltd., 514/685-2630. www.matrox.com |

Mettler-Toledo Hi-Speed, 607/257-6000. www.mt.com/hi-speed |

Mettler-Toledo Safeline, 813/889-9500. www.mt.com/safelineus |

Nercon Engineering & Manufacturing Inc., 920/233-3268. www.nercon.com |

Nordson Corp., 770/497-3700. www.nordson.com |

Rockwell Automation, 414/382-2000. www.rockwellautomation.com |

Sato America Inc., 704/644-1650. www.satoamerica.com |

Videojet Technologies Inc., 800/843-3610. www.videojet.com |

Wonderware, a business unit of Invensys Systems Inc., 949/727-3200. www.wonderware.com |

Yamato Corp., 262/236-0000. www.Yamatocorp.com |

About the Author(s)

You May Also Like