How to Balance Food Waste Versus Packaging Waste

It’s not an either-or proposition. We must address both waste streams — food and packaging — to see the best environmental results for a circular economy.

The world faces two adverse situations regarding solid waste management: food waste and packaging waste. These two major solid waste contributors lead to economic, environmental, and social challenges. The US Environmental Protection Agency reports that 45% of total US solid waste consists of these two wastes, and though we have many technologies for managing our global waste, the majority still goes to landfill.

Let’s start with food waste.

Astonishingly, more than one third of the total food produced globally is not consumed and goes to waste. The annual global value of food-as-waste is $1 trillion and it weighs 1.3 billion tonnes. To help visualize the amount, imagine an area larger than China that grows food that becomes waste.

All the hungry people in the world can be fed on less than quarter of the food that is wasted, according to Alessandro Demaio, CEO of Norway-based EAT, an international non-governmental organization (NGO) fighting worldwide hunger. Food waste happens at all stages: production, processing, transportation, retail, and consumer. Some of the waste is unavoidable; however, the majority can be prevented.

The issue doesn’t end here. The wasted food uses 25% of all water used every year for agricultural purposes.

Now, let’s look at plastic waste.

Plastic waste has been a hot topic among environmentalists. And, globally, its management has become a pressing priority.

Among all the plastic waste, packaging waste has been targeted because the rapidly increasing production of disposable plastic products overwhelms the world’s ability to deal with their disposal. Today, single-use plastics account for 40% of plastics produced every year and many of these products — such as plastic bags, food wrappers, and food packaging — have a lifespan of mere minutes to hours, even though they remain in the environment for hundreds of years. Plastic is polluting our lands, oceans, and affecting planet life.

How the “waste” debate adds up.

People have been debating whether plastics create more damage to the earth than benefit. Let us evaluate this from food packaging point of view.

Plastics, being non-biodegradable, remains on the land and in oceans. Their impact is visible everywhere. But the decomposition of food, which everyone thinks degrades naturally, is a significant contributor to global warming.

Environmental impact of waste is calculated as Global Warming Potential (GWP), which is higher for food waste than for packaging waste. Research says that 1 tonne of food in a landfill yields 1,010 kilograms of CO2, which is same amount of CO2 emitted if you drove for 2,000 miles. In addition, food decomposition also emits methane, which is more potent to the environment in terms of global warming potential. If food waste or loss was a country, then it would be the world’s third largest emitter of greenhouse gases, according to the United Nation’s Food and Agriculture Organization (FAO).

Another way of thinking about the impact of waste is to consider the amount of energy used in production. If we measure the water and energy used to manufacture food products — as well as the energy used in transportation, storage, and cooking — its collective impact on environment would be much higher than its packaging. For example, bread production consumes 15.8 megajoules (MJ) of energy, while packaging of bread requires 1.4MJ of energy for production. This might imply that, by removing packaging, we can save 1.4MJ of energy. But without packaging, accelerated spoiling of bread will lead to loss of 15.8MJ of energy.

There is one more aspect to food waste’s environmental impact: excess nutrients from land enter the water and changes its composition and pH by feeding algae and bacteria. This also results in a change in oxygen levels, killing off fish and causing an imbalance in the marine ecosystem.

There is no doubt that food waste is causing more burden on the environment than packaging waste. Food waste or losses are even more disturbing when we know that millions of people still do not get enough food to eat. A study from the Flexible Packaging Association (FPA) claims that two thirds of food waste is due to spoilage, while one third is due to oversupply.

In the prevailing scenario, it is crucial that we have methodologies to minimize food waste through packaging, while also optimizing the whole packaging cycle to have minimum impact on environment. For the circular economy and sustainable development, all resources should be used to their maximum, whether it be packaging or food.

So, rather than eliminating packaging, the industry should choose packaging materials and designs that keep food from spoiling.

Packaging solutions to help minimize food waste.

Food waste or losses happen at every stage, be it food production, transportation, storage, processing, or cooking. Packaging plays a major role in eliminating or minimizing losses during transportation and storage.

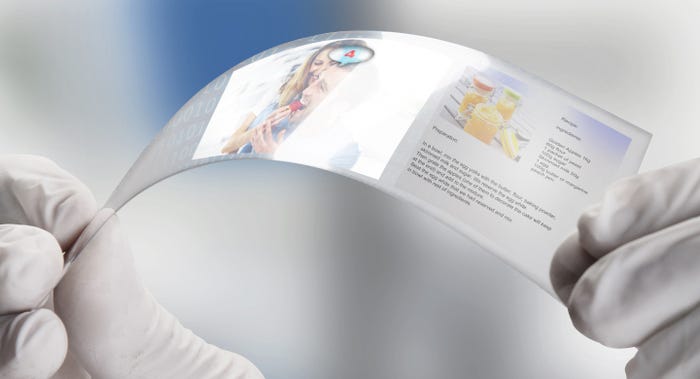

Another way of protecting food and reducing packaging is to tap into new technologies like these three: active packaging, barrier films, and nanotechnology.

1. Active packaging, such as modified atmospheric packaging (MAP), contributes to preventing fresh produce losses. The right packaging, coupled with correct storage temperatures, can extend a product’s shelf life by creating conditions in the packaging that delay maturation and ageing of fruits and vegetables.

2. Barrier films contain small amounts of barrier materials or coatings to protect against oxygen and/or moisture, and thus enhance the food’s shelf life while minimizing the amount of packaging. However, sometimes barrier layers prevent the multilayer film from being recyclable. So only use them when needed. On the other hand, a low-barrier film may result in food spoilage sooner and losses.

3. Nanotechnology has recently emerged in food packaging to help extend shelf life. You can enhance a package’s barrier properties by using nanoparticles such as clay, which when mixed with polymer matrix improves the gas barrier. Other nanotech examples are silver nanoparticles that can improve the anti-microbial properties, or nanosensors added to smart packaging as a tracking device for food safety. Using these technologies, you can prevent or minimize food waste without negatively affecting recyclability since nanomaterials are added in such small concentrations that they don’t affect recyclability of the base packaging material.

How a package is used also matters.

Certain packaging functions at various stages can also help reduce food waste and losses. These functions could be related to efficient product handling throughout the supply chain or to convenience through other packaging performance characteristics.

Regarding handling, a package should be easy to handle and replenish without mechanical damage, which could lead to waste. Other package functions — like easy opening, complete dispensing, and reclosability — can also help reduce food spillage and waste.

The package size should also reflect its use and be optimized depending upon market and consumer choices. For example, a lot of food could get wasted in small households if they buy large packages and are unable to finish the product before it goes bad. However, buying too many single-serve packs may lead to more packaging waste than is necessary.

You could conduct a life-cycle analysis that measures the amount of food waste for two different packaging systems (based on size) of the same product, to determine the effect of the packaging size. For example, packaging for sliced cheese has a much higher global warming potential than the packaging for a block of cheese, but the food waste was significantly higher for the block compared with the sliced product.

Communicating the function of packaging — such as information about food freshness, safety, and standardized date labeling — can also affect food waste. This helps in inventory control and monitoring the shelf life of food products.

Finding the right balance.

The environmental impact of packaging has typically been focused on its direct impacts — the life cycle of the packaging material itself — without regard to the indirect influence on food waste. But when designing packaging for a food product, evaluate the environmental impact of both food waste and packaging waste to assess the overall consequence.

Apart from this, you can reduce the adverse outcomes of a package by: removing excessive packaging; using smart packaging; reducing the packaging weight; choosing recycled content and/or renewable materials; and improving on the collection and recycling of empty packaging.

Few changes in packaging functionality and design may have a great impact on preventing food waste and losses. It’s a fine balance of protecting food adequately and using packaging materials optimally. We must do both to save resources, reduce environmental impact, and increase overall system efficiency.

For food, use short and local food supply chains, and efficient packaging.

For packaging, eco-designing, reusing, and better recycling can be complementary strategies for developing a circular economy.

About the Author(s)

You May Also Like