Kraft Foods saves 800,000 lbs of paper annually with new retail-ready shipper

Kraft Philadelphia 24 count RRP

Shopping for Philadelphia 8-oz Brick Cream Cheese is now easier for retail customers due to the redesign of a Retail Ready Shipper (RRS). Now available nationwide, brand owner Kraft Foods estimates it will save 800,000 lbs of total paper usage annually.

Jordan Dasher, engineer, Cheese & Dairy, Kraft Foods, says, "The change on the Philadelphia Brick business was made to reduce overall paper usage within its shipping cases, reduce the steps needed for displaying and provide shop-able outer packs to the consumer-a growing trend within U.S. retailers."

Development of the retail ready case included a partnership with Kroger to help understand shopper and retailer reactions to the new package prior to launch. The in-store test and partnership provided timely feedback to the Kraft team on ease of opening, shelf fit, graphic placement and accessibility and usage of the new pack to succeed in the targeted packaging reductions.

Specifically, the newly designed RRS:

● Eliminates the previous 12-count display carton: Dasher explains, "The previous corrugated cases were comprised of two or three display cartons, depending on SKU. Each display carton contained 12 individual 8-oz Bricks. The new Retail Ready Shippers now house and display the individual 8-oz Bricks with elimination of the 12-count displays."

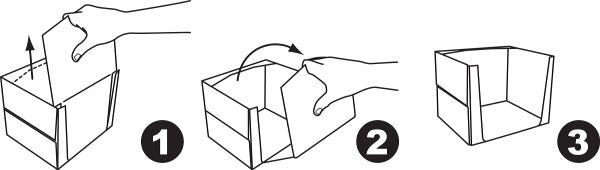

● Provides a functional, easy-to-open retail-ready package: "The new outer cases leverage the use of perforated rule profiles, an opening hand hole and printed case directions to make a single motion opening for the retailer stock person," Dasher says.

● Withstands refrigerated distribution environment: Specified to perform in temperatures of 35 to 45 degrees F, the corrugated board combination was selected and tested to meet Kraft's compression requirements to withstand the refrigerated distribution supply chain.

● Reduces steps for retail customer to stock and fit within current shelving: "The previous shipping cases took up to 15 steps to open and stock on shelf, including opening of the corrugated case and 12-count display cartons. The new case takes three by pulling at the hand hole, removing the front panel and tearing off the lid to stock on shelf," Dasher explains.

Kraft Philadelphia RRP opening instructions

● Improves sustainability benefits by reducing paper usage: Although the new RRP case design required an increase in the corrugated board combination to protect the primary packages, eliminating the 12-count display cartons netted approximately 800,000 lbs of total paper reduction.

The RRP case is being used for all Philadelphia Brick products in the U.S., but not globally. As mentioned earlier, Kraft partnered with Kroger to validate the case design before making the switch, but Dasher says all U.S. retailers are taking one or more of the new RRP case sizes. There are five RRP SKUs total: 12-, 24- and 36-count for retail outlets, and 6-count and 6-packs for club stores.

Kraft Foods plans to extend this style of retail-ready display case to other brands "but only if applicable for the primary package," Dasher adds.

.

About the Author(s)

You May Also Like