Meet the First 3-ounce Retort Carton in the US

While initially targeting premium pet foods, the co-manufacturer of the single-serve Tetra Pak Recart package is geared up for production volumes of approximately 50 million units for any food.

What do you call a package that offers product differentiation, shelf appeal, consumer convenience, and sustainability — and is cost effective? Most people would call it a winner.

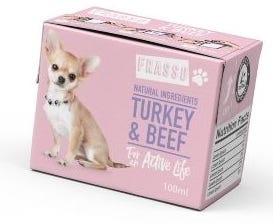

NaturPak Pet, a leading co-manufacturer for premium pet food, now has the capability to produce the new 3-ounce/100-milliliter Tetra Pak Recart retort carton. Tetra Pak introduced its 100 Mini Recart package in June 2023 in Spain. With NaturPak Pet’s multi-million-dollar investment, the unique pack is now available here in the United States.

With an initial push into the premium pet food market, Aaron Jackson, CEO of NaturPak Pet, sees broader potential. “We’ve seen incredible interest in the pet food industry. However, our ambitions extend beyond the pet food market,” Jackson says. “We are actively exploring opportunities in the human food industry as well. The same advantages that make our packaging appealing to pet food brands can also be leveraged in the human food category.”

Expect to see this package on shelves soon. NaturPak Pet has several customers launching products in this new package later this year in mass-merchandise outlets, club stores, and traditional pet channels.

Why do we need a single-serve retort carton?

The Tetra Pack 100 Mini Recart offers premium food brands an alternative to the typical can or pouch for small portions. Single-serve packaging, mostly plastic single-use packs, have been criticized for their environmental wastefulness, despite their convenience and other benefits like affordability. NaturPak Pet acknowledges these valid concerns but points out that this package is made primarily of paper and is recyclable.

Other than being made of a renewable packaging material, what are the advantages of this size and format? Already mentioned in the first sentence, let’s take them one at a time.

NaturPak Pet

Attractive and versatile, the single-serve retort carton gives manufacturers of premium foods a new option to differentiate their brands.

• Product Differentiation and Shelf Appeal:

Jackson sees this unique format and size as a catalyst for category and brand growth in the pet and human food industry.

“Brand owners and retailers are actively seeking ways to stand out on the shelves,” he says. “Our packaging is not only functionally superior but also perceived as premium by consumers. Its unique shape, packaging benefits, and the powerful billboard branding effect make it an ideal tool for driving brand recognition and differentiation.”

By “functionally superior,” Jackson is referring in part to the package’s extended shelf life as a shelf-stable package. “The shelf-stable nature of our package helps to preserve the freshness and quality of the product for an extended period,” he says. “This is particularly advantageous for both consumers and retailers as it reduces the likelihood of product spoilage and wastage, ensuring that customers can enjoy the product at its best for longer.”

Cube efficient, the carton is compact and stackable, making good use of shelf space in a consumer’s pantry — as well as in stores. Retailers can optimize shelf displays, as well as save space in their backroom storage.

• Consumer Convenience:

The Tetra Recart pack is easy to open without tools. Consumers unfold the top, pinch it to flatten it a bit, and tear along the perforated line across the top.

Dispensing and product evacuation are smooth, even with a solid, compact pack. Jackson explains, “Our packaging technically has six layers of protection, the inside being polypropylene, which not only provides a powerful barrier, but allows product to easily slide out of the carton. Whether it’s a solid pet food pate or cranberries for the holidays, both easily dispense, hassle free, from the carton.”

The package is not microwavable. But Jackson says this feature has not come up in most conversations with customers and retailers.

While the package is recloseable, the small volume means that most applications will be for single-serve portions. “There is significant consumer need and demand for single-serve options that are simply better than the current alternative,” Jackson says. “That is what we are bringing to market.”

The versatile pack is also suitable and convenient for ecommerce sales, which continue their double-digit growth in the US. “Pet owners are more discerning than ever, which means a focus on healthy food is a requirement, but so is a convenient, sustainable packaging format,” Jackson says. “Sales channels for Pet Food are diverse and ecommerce continues to grow. Simply put, our packaging format is the best option for brands that desire to ship products direct to consumer.”

• Sustainability:

NaturPak Pet recyclable food cartons are made mostly from fiber, touted as “a renewable resource that produces minimal environmental impact.” Tetra Pak backs up that statement with a lifecycle assessment of its Recart package for soup that scores better than steel cans and flexible pouches. NaturPak Pet explains on its website: “A pet food steel can will languish in a landfill for nearly a half-century. Plus, steel is heavier than paper, which is why a pallet of cans requires a great deal more energy to move from plant to warehouse to store.”

Paper packaging seems to be the go-to material these days, from a sustainability point of view. And Jackson expects this will be a selling point for NaturPak Pet’s newest offering. “Certainly, the sustainability aspect of paper packaging is a major selling point for our new package,” Jackson admits. “It aligns not only with consumer preferences but also with the desires of retailers and brands.”

Especially in a category — premium pet food — that lacks environmentally friendly packs, a paper-based option aligns with retailers’ strategies to attract environmentally conscious shoppers.

And as for brands’ strategies: “Brands are increasingly emphasizing sustainability as a core value. Our paper packaging allows brands to align their products with these values, demonstrating a commitment to environmental responsibility,” Jackson says. “This messaging resonates well with consumers and can enhance brand reputation and loyalty.”

• Cost Effective:

Many traditional packaging formats — cans, pouches, and jars, for example — require high minimum order quantities (MOQ). Smaller brands with lower-volume product lines or entrepreneurs experimenting with new products can find this cost prohibitive. The NaturPak 3-oz retort carton has a low minimum (45 thousand per stock-keeping unit/SKU), helping to make this innovative package accessible to more brands. “We are not only meeting the demands of premium brands but also democratizing access to high-quality packaging,” Jackson says, “thereby fostering innovation and flexibility in the market.”

Because products are shelf stable, distribution costs are controlled. Eliminating the need for refrigeration during transit reduces energy consumption and transportation costs.

And because packages are cube efficient with little headspace, more products fit on a pallet compared to cans (1,728 cartons vs. 1,560 cans). “Because of its optimal fill levels and the compact shape of the box,” Jackson says, “we can fit more units of our product in trucks compared to traditional packaging formats like cans or pouches. This means fewer shipments are required to transport the same quantity of products, resulting in cost savings in terms of fuel, labor, and logistics.”

And when it comes to preventing costly food waste from damaged packaging, the 3-oz carton adequately protects enclosed products during transport. “Unlike pouches or dented cans, which can lead to product damage, our packaging helps maintain product integrity,” Jackson says. “This reduced risk of damage ensures that products arrive at their destination in excellent condition, leading to more reliable delivery and a better overall experience for consumers.”

The better the experience, the more likely the consumer will be a repeat buyer.

All these benefits contribute to a sustainable and cost-effective packaging solution.

An inside-look at the plant and packaging line.

NaturPak Pet has two manufacturing plants in Janesville, Wisconsin, that can produce approximately 50 million units of this new packaging format annually. View the slideshow to see photos.

This project represented an investment of several million dollars — “Apologies for the vague answer on the specific cost of the project, but I’m sure you can understand the sensitivity,” Jackson says. NaturPak Pet bought Tetra Pak TPR2 lines with custom volumetric conversion kits that allow them to produce the smaller size.

The retort process is still being calibrated. But Jackson says retort time for the square package will be shorter than for a rectangular shape. Retort time for the Tetra Recart 100 Mini will be about 2 hours vs. the typical average of 2.5 hours — so 20% less time.

For a premium food brand, this could make quite a difference in product quality. NaturPak Pet explains on its website: Prolonged exposure to heat robs foods of nutrients and taste, which is why many of us humans have noticed that foods like soups and vegetables taste better from a carton than a can. Our furry friends also prefer the same freshness and taste from pet foods packaged in cartons.

User-friendly, attractive, and environmentally conscious, this small retort carton has big potential for product innovators in competitive markets.

Lisa McTigue Pierce is Executive Editor of Packaging Digest. She’s been a packaging media journalist since 1982 and tracks emerging trends, new technologies, and best practices across a spectrum of markets for the publication’s global community. Reach her at [email protected] or 630-272-1774.

About the Author(s)

You May Also Like