Antimicrobials Grant Superpowers to Food Packaging

Packaging that releases antimicrobials into foods can boost shelf life, reduce waste, and combat villainous mold and nasty pathogens.

March 15, 2021

Consumer desire for longer shelf life and less preservatives have spurred advances in antimicrobial packaging. Often antimicrobial packaging agents are GRAS (Generally Recognized as Safe), “clean label,” and only added when needed.

Antimicrobial packaging releases antimicrobials into foods such as minimally processed deli meat and seafood, fresh and slack (i.e., frozen then thawed) fruits and vegetables, cheese, and baked goods. This release reduces food safety risk by inhibiting mold and nasty pathogens such as Campylobacter, Escherichia coli, Listeria monocytogenes, and Salmonella.

By selecting packaging materials with a specific glass transition (Tg, an amorphous to crystalline state transition) that synchronizes antimicrobial release with microbial growth temperatures, antimicrobials can be "automatically" metered as needed over a product's shelf life.

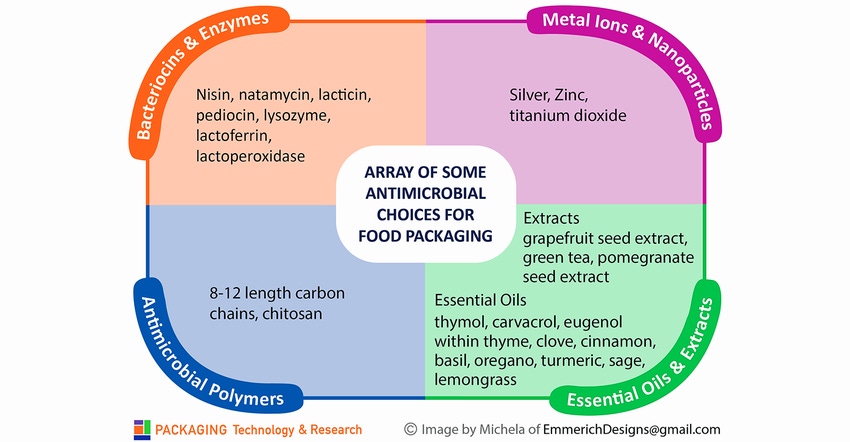

Yes, there is an array of choices! To assess if products and packaging can benefit from antimicrobial packaging, an initial screening is critical. Antimicrobials used in food packaging include bacteriocins, enzymes, essential oils, selected polymers, metal ions, and inherently antimicrobial polymers. These antimicrobials and screening criteria for implementing viable antimicrobials are discussed.

Types of Antimicrobials

Bacteriocins and Enzymes

Nisin, natamycin, lacticin, pediocin, lysozyme, lactoferrin, and lactoperoxidase have antimicrobial activity. Nisin is the most commonly used bacteriocin, often on dairy products and minimally processed vegetables. Nisin is GRAS and effective against Clostridium, Listeria monocytogenes, Lactobacillus, Staphylococcus aureus, and Micrococcus.

Essential Oils and Extracts

The use of essential oils in packaging is increasingly popular due to their consumer-preferred “clean label” status. Essential oils that impart antimicrobial activity include thymol, carvacrol, and eugenol within thyme, clove, cinnamon, basil, oregano, turmeric, sage, and lemongrass. Fresh and processed meat, seafood, poultry, and fresh and cut-produce use in antimicrobial packaging. To prevent off-flavors and to stay below regulatory limits, only 0.2%–2% essential oil is viable. Due to this, combinations of essential oils and extracts are often used.

Metal Ions and Nanoparticles

Silver and zinc metal ions and their nanoparticles — with a high surface area to volume ratio — are viable for antimicrobial packaging use. The FDA has approved silver nitrate in foods with a limit of 0.017 mg/kg and 5% silver zeolite. And a maximum food migration limit of 0.05 mg/kg is approved in the EU.

However, the associated environmental and biological concerns using nano-sized compounds is the subject of much legislation.

Antimicrobial Polymers

Polymers that provide antimicrobial properties include carbon chains from 8 to 12 and chitosan. These are often combined with the other antimicrobial agents mentioned to provide expanded array of antimicrobial properties.

Implementing Antimicrobial Packaging

The field of antimicrobial packaging involves a complex array of choices. An initial product-specific screening to determine the viability of the antimicrobial packaging includes:

Capability of existing packaging to retain and release antimicrobials;

Antimicrobial efficacy toward specific microbes;

Temperature of use;

Shelf-life requirements;

Regulatory limits;

Sensory limits;

Value chain analysis of benefit;

Cost profile;

Impact on the environment;

Impact on compostability;

Opportunity for intellectual property or trade secrets

Once viable antimicrobial options are ranked, product-specific testing is needed to assess and refine the selected antimicrobial technology. Antimicrobial packaging is being “rediscovered” as a solution to provide consumers with “clean label” food with a longer shelf life.

Claire Sand, PhD, has 30+ years of experience in industry and academia. She's owner of Packaging Technology and Research and Gazelle Mobile Packaging and is an Adjunct Professor, CalPoly, Michigan State University, and the University of Minnesota. Her email is [email protected]

About the Author(s)

You May Also Like