January 29, 2014

While customers visiting one of Italian supermarket chain IPER's 22 stores might be surprised to come upon a walking, talking ear of corn, they may be even more amazed when they learn the message being relayed by IPER's new maize mascot about the unique nature of the store's fresh food packaging. In mid-2002, IPER launched an innovative program to enhance its commitment to high-quality, fresh foods through the use of environmentally friendly packaging made from Cargill Dow's corn-based NatureWorks™ PLA resin (see PD, July, '02, p. 30).

Mario Spezia, IPER sales director, noted at the time that NatureWorks would allow IPER to provide its customers with a natural food product protected by a natural package–an important combination, he said, that would enable the chain to differentiate itself from the competition.

|

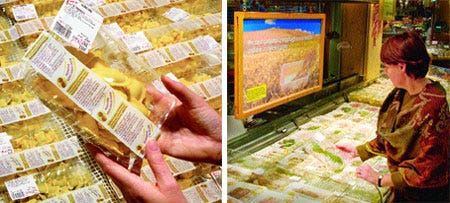

Italian supermarket chain IPER uses walking, talking ears of corn, right, to relay its marketing message on the store's use of packaging made from corn-based resin for its fresh foods. Other methods include printed messages on its containers, left, and point-of-purchase displays, above. |

Now, 18 months later, with the seeds of change sown at all 22 of the chain's locations, IPER is busy educating its customers on the benefits of its "natural in natural" products, as well as looking for new opportunities to expand the use of NatureWorks to other food applications.

PLA gains acceptance

Developed by Minnetonka, MN-based Cargill Dow, LLC, NatureWorks PLA resin is produced when carbon is harvested from 100-percent renewable resources. With the opening of its first large-scale production facility in Blair, NE, in April, 2002, Cargill Dow became capable of producing up to 300 million lb of the polylactide (PLA) polymer per year through the use of 40,000 bushels of locally grown corn per day (see sidebar).

According to Cargill Dow, the breakthrough technology used to produce NatureWorks PLA utilizes 20-percent to 50-percent less fossil resources than are required to make petroleum-based resins and generates 15-percent to 60-percent less greenhouse gasses (GHGs) than the material it replaces. In terms of the resin's performance, the company says that NatureWorks PLA offers a number of characteristics equal to, or better than, traditional, petroleum-based polymer packaging. These include high clarity and gloss, with a 2.1-percent haze; unique flavor and aroma barrier properties; excellent resistance to most oils and fats used in food products; and low-temperature heat-sealing requirements of 176 deg F, with heat-sealing strengths of greater than 2 lb/in. Extremely versatile, the material can be used to make flexible films, rigid containers and bottles, and can be oriented, thermoformed, coated and printed with existing converting equipment at high speeds, reports Cargill Dow.

When IPER began test-marketing containers made from NatureWorks in fall, 2001, it was one of just a handful of companies experimenting with the resin for both food and nonfood applications. Other early adapters included The Coca-Cola Co., which premiered venue cups made from NatureWorks PLA at the 2002 Olympic Winter Games in Salt Lake City; Sumitomo Rubber Industries and Mitsubishi Plastics, which selected the polymer for Dunlop golf ball packaging; and Unitika and Sony, which used NatureWorks PLA in a film wrap for Sony mini-discs.

Today, applications for NatureWorks PLA have expanded to include foodservice packaging, egg cartons, pasta trays, twist wrap for organic hard candies (see PD, Dec., '03, p. 10) and disposable cutlery, among others, in both Europe and the U.S. (see PD, Apr., '03, p. 4). While IPER is no longer the only grocery chain in Italy promoting NatureWorks PLA, it "remains the leader in using the nature-based packaging both in terms of volume and breadth of applications," relates IPER packaging team coordinator Paola Zorzoli.

Education is key

As IPER related to PD back in mid-2002, the decision to convert to PLA packaging was not based on economics. In fact, at that time, it was estimated that the cost of PLA was approximately twice that of polypropylene–a figure that has not changed since. The financial advantages, therefore, are calculated through more abstract measures. Says Stefano Cavallo, business development manager at Cargill Dow BV, "NatureWorks PLA offers all the convenience of traditional packaging while helping reduce environmental impact. This can help food retailers turn their packaging into a source of brand advantage to capture shopper attention, improve customer loyalty and increase fresh food sales."

Vital to the program's success is IPER's marketing message. An in-store advertising campaign designed with the help of Cargill Dow was rolled out at the same time as the new packaging. It includes:

• Roaming ears of corn that greet shoppers and distribute informational pamphlets;

• Banners, posters and point-of-purchase displays to attract customers to the fresh products in NatureWorks PLA packaging;

• Printed messages on film lids; and

• In-store special events.

"The educational program is very important, as it teaches customers that what looks like ordinary packaging is actually made from maize," says Zorzoli. "All of our personnel are informed about our company's choice to use the packaging, so they can explain the benefits to customers."

|

|

New to IPER's compostable packaging offerings are paper bread bags, top and above left, with film windows made from PLA film. Other products using the environmentally friendly film include fresh fruits, vegetables, pasta, salads, ham, sliced salami and cheese, above right. |

IPER expands use of PLA

IPER originally introduced NatureWorks PLA thermoformed containers heat-sealed with film lidstock for its fresh fruits, vegetables, pasta and salad offerings. Since then, applications have grown to include tomatoes, ham, sliced salami and cheese, formerly packaged in polyethylene terephthalate and PP trays. All products are filled and sealed in-store, except for tomatoes, which are packed in thermoformed containers from Italian packaging supplier Ilip before being delivered.

Rigid deli containers are supplied by Autobar Disposables Group, which worked with IPER to design 12 different package sizes. The containers are made from 330-micron sheets of NatureWorks PLA produced on a standard cast extrusion line. Film lidstock, gravure-printed with marketing information, is sourced from Trespaphan in 20- to 25-micron thicknesses. Notes Zorzoli, since first introduced in summer, 2002, the deli packaging has not been changed. "It has performed well in the application," she says.

"NatureWorks PLA looks and acts like traditional plastic packaging, providing high clarity and gloss for showcasing food products," Zorzoli adds. "In addition, it is strong and durable to protect food and retain freshness."

One new area of use for NatureWorks PLA at IPER is windowed paper bread bags, supplied by Sacchettificio Turconi and another supplier, with windows made from the nature-based resin. Says Zorzoli, because the PLA film is more "breathable," bread can now be placed in the bags while still hot, without condensation forming on the window.

Future applications abound

At the outset of IPER's conversion to NatureWorks PLA packaging, the company had estimated that its use of the resin could reach 50 tons/yr, with all stores on-board. In just over a year and a half, though, the company has reached a consumption level of 100 tons/yr and is continuing to explore new packaging avenues.

"Switching to nature-based packaging is helping us bring new attention to our fresh foods," says Spezia. "NatureWorks PLA offers a high-quality container and gives us a significant opportunity to market the environmental benefits to our customers."

Looking to the future, IPER is considering putting its in-store brand of fresh produce, Patto Qualit?, in NatureWorks packaging. In addition, it is testing several new applications in PLA, including standup pouches for cookies and bread, vacuum-sealed applications, such as cheese and sliced salami, and trays for packaging meat, poultry and fish.

More information is available:

PLA resin: Cargill Dow LLC, 877/423-7659. www.cargilldow.com. Circle No. 201.

Thermoforms: Autobar Disposables Group, +44 (0) 20 8326 8000. www.autobar.com. Circle No. 202.

Film lidstock: Trespaphan GmbH, +49-(0)6142-200-0. www.trespaphan.com. Circle No. 203.

Bread bags: Sacchettificio Turconi, +39 2 967 01182. www.sacchettificio-turconi.com. Circle No. 204.

Cargill Dow satisfied with progress | ||

In April, 2002, Cargill Dow LLC brought on-line the first global-scale manufacturing plant capable of making commercial-grade plastic from annually renewable resources for use in the packaging and textile industries. Recently, Cargill Dow's corporate communications director, Michael O'Brien, spoke with PD about how the facility is meeting the company's production goals and the impact of NatureWorks™ PLA on the packaging sector. |

About the Author(s)

You May Also Like