Compact labeler tailored for food and beverage packaging

May 23, 2018

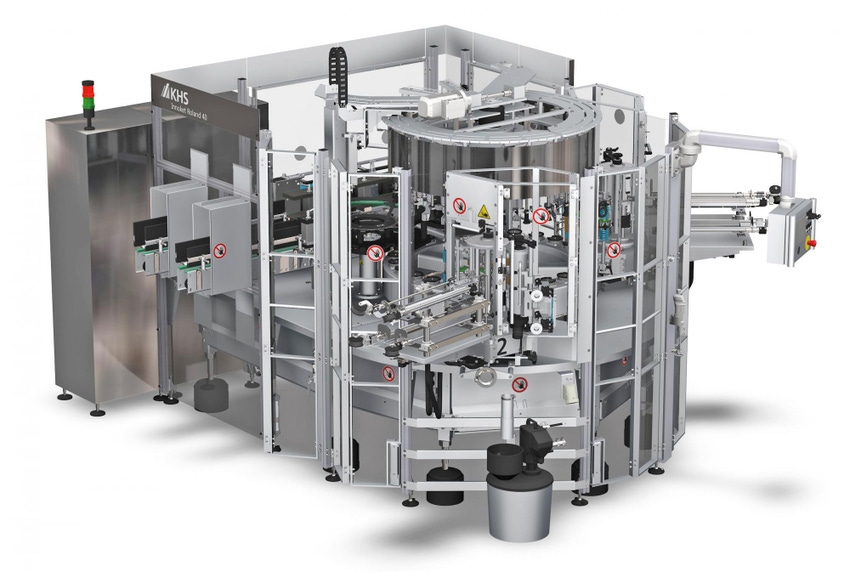

The KHS Innoket Roland 40 has a capacity of 2,500 to 25,000 containers per hour and is engineered for simple, reliable and economical labeling of cans and bottles.

KHS Group’s family of Innoket labelers has grown with the introduction of the Innoket Roland 40 compact labeler. The KHS Innoket Neo’s little brother has a capacity of 2,500 to 25,000 containers per hour and is specifically tailored to the requirements of the food and beverage industries. The Innoket Roland 40 can be fitted with various labeling stations and is characterized by its ease of use using KHS' high-quality components.

“The machine is specially geared towards lines with a low output,” says Cornelius Adolf, labeling product manager at KHS. During development particular attention was paid to simple, economic operation.

Adolf informs Packaging Digest that the labeler accommodates metal food cans, glass bottles and PET bottles with a minimum/maximum diameter of 45mm/129mm or and a minimum/maximum height of 110mm/ 380mm. The labeler accepts either cold adhesive paper or polymeric labels or pressure-sensitive labels.

The standard version Innoket Roland 40 offers two cold glue stations to allow shoulder and neck labels to be applied at two levels by the first station, for instance, with the second station affixing back labels to the bottles. Alternatively, self-adhesive stations, a combination of cold glue and self-adhesive technology and hot-melt labeling processes, can be used.

Besides its applicability for a range of packaged foods including canned foods and bottled sauces and dressings, Adolf tells Packaging Digest that he expects the most promising beverage markets to be for craft brewers and spirits brands running bottles.

“A couple of machines have been sold and are being installed and tested currently,” he adds.

Inside the Roland 40 are components similar to the high-performance KHS Innoket Neo labeler such as the carousel, infeed and discharge stars, swiveling doors for easy access, format parts and guides and the gripper cylinder and label magazine on the cold glue station. The Innoket Neo servo-feed screw is integrated on the Roland machine, permitting gentle bottle stops.

Adolf also points out that the control standard is a larger new 21.5-inch human machine inetrface rather than the small HMI seen in a YouTube video that offers viewers a 360 degree virtual tour (shown above).

Numerous customizable options

Adolf also points to a number of available options to customize the labeler for specific customer needs:

KHS VarioDrive electronic bottle control system;

Mechanical bottle orientation found in the infeed starwheel via the bottles’ side notch;

Traveling press-on units in carousel fitting, for example for cap or lid labels;

Foiling head;

U-shaped labels including tamper-evident seals for twist-off caps can also be labeled and rolled on.

Processing of L-Stripe labels, for example for tax stamps;

Sensor package that checks for label presence at certain points, for example in the label magazine or on the gluing roller, and for other factors such as broken bottles.

The machine will be on display at Anuga FoodTec in the Florin Gesellschaft für Lebensmitteltechnologie mbH booth located at E20/F29 in Hall 10.1.

___________________________________________________________________________________

You’ll find the latest cobots, a dedicated 3D Printing Zone, hundreds of exhibitors and a 3-day packaging conference at the Jacob K. Javits Convention Center during EastPack 2018 (June 12-14; New York City).

___________________________________________________________________________________

You May Also Like