‘Configurable’ labelers minimize floor space, maximize versatility

August 27, 2018

How easy is it for your packaging line to accommodate new products and new packages, especially when you have limited floor space? A new line of compact labelers from a major equipment manufacturer has the potential to meet a range of user requirements, for both machinery configuration and label type.

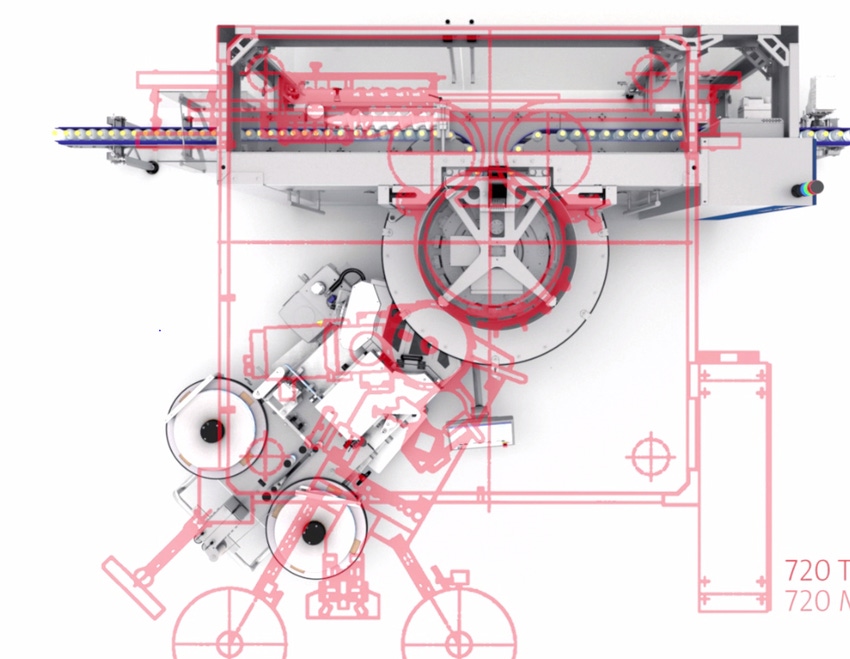

The EM Series from Krones comprises three main machines, six table diameters and seven labeling station types. It offers numerous options for combining these individual elements, allowing end users to configure systems for many different types of applications.

Mix-and-match equipment options include:

• The Ergomodul, a columnless machine with exchangeable labeling stations;

• The Ergomatic Pro, Canmatic Pro and Autocol Pro columnless machines with fixed labeling stations;

• The Ergomatic, Contiroll, Canmatic and Autocol tabletop machines. These handle, respectively, precut labels with cold glue; reel-fed labels with hot-melt glue; precut labels with hot melt; and reel-fed self-adhesive labels.

The columnless machines feature a table top and support made of stainless steel, with an aluminum container table (with stainless as an option). Its slim design gives it a significantly smaller footprint than other equipment of comparable throughput, making it easy to integrate into existing lines. “The footprint of the ErgoModul is 15% to 20% smaller than our traditional tabletop labeler with the same carousel size and the same components,” says Michael Soloway, product manager–Labeling for Krones Inc.

The columnless machines use uniform servomotors for the main drive, infeed and discharge starwheels and infeed worm—which simplifies stocking of replacement parts. These require no lubrication, reduce noise, are highly energy-efficient, and can furnish feedback for preventive condition monitoring. A single touchscreen controls the main machine, labeling stations and all PLCs for simple operation.

The tabletop machines come in a CL (classic) line for low to medium outputs, and a TS (top speed) line for high output. Their benefits include hygienic design, optimal cleaning properties, highly accessible change parts, reduced energy consumption, optional anti-static equipment for the reel-fed machines, optional contact-free glue application, and robust technology for leading-edge gluing and trailing-edge gluing.

The EM series is designed to be homogeneous, no matter how the elements are configured.

What does “columnless” mean and why is it significant? Soloway explains, “Our older modular machines had support columns around the perimeter of the product carousel, and those columns were often in our way when we mounted labeler heads, brushes, inspection equipment and coding equipment. In some cases, we had to build a larger machine to be able to mount all of the components that we needed simply because the columns prevented us from using the space in the carousel in the most efficient manner. The new columnless design has all of its support through the center shaft, which leaves the perimeter of the carousel wide open to mount components anywhere we want to. We can now optimize the columnless machines for each application to be as small and as efficient as possible.”

How are the columnless systems different from the tabletop units? Again, Soloway explains, “Tabletop machines are essentially square or rectangular-shaped machines. The product carousel sits inside a rectangular framework on what we call a table plate. For the operator or maintenance personnel to reach the components inside the machine, they often need to climb up onto the table plate inside the machine. The columnless machines have a round shape that matches the perimeter of the carousel, so the operator or maintenance personnel can walk right up to the carousel and have easy access to the components without having to crawl inside the machine. Of course the tabletop machines are less costly to build than the columnless modular-style machines, so they remain very popular.”

Columnless or tabletop, the Krones machines easily integrate with other machines on the packaging line with a simple connecting conveyor.

Krones will introduce the EM series of labelers in Booth S-2138 at this year’s Pack Expo (Oct. 14-17; Chicago).

********************************************************************************

Packaging solutions come to Minneapolis: As part of the region’s largest advanced design and manufacturing event, MinnPack 2018—and the five related shows taking place alongside it—brings 500+ suppliers, 5,000+ peers and 60+ hours of education together under one roof. Register for free today.

About the Author(s)

You May Also Like