A lot of rigid containers are topped with continuous-thread closures. One way those caps are automatically applied to bottles is with a spinning disk capper.

May 5, 2023

Spinning disk cappers are a popular alternative to the more mechanically complex chuck cappers. One advantage is that they can run different caps and bottles with few or no changeparts. A new bottle can be run on a disk capper this afternoon. A rotary chuck capper might require three to five weeks for parts before it can run a new package.

A slight disadvantage of spinning disk cappers, though, is that they can only run round caps.

Step-by-step of a spinning disk capper.

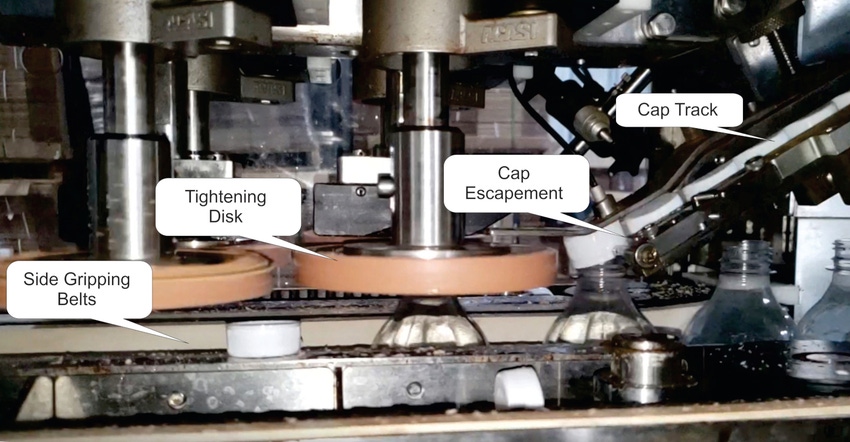

Capping starts with a cap orienter above the capper to properly position them for automatic placement. Caps exit the orienter open side up into a “C” track. This inverts and feeds them open side down to the cap escapement.

Caps are positioned in the escapement at a slight angle. Spring-loaded fingers hold the bottom cap in position.

As the bottle enters the capper, it is captured by side belts. One pair of belts (shown above) is common. Two pairs, one above the other, may be used for tall or unstable bottles.

As the belts pull the bottle through the escapement, the outside leading edge of the bottle neck catches the inside leading edge of the cap. This pulls the cap from the escapement. A curved block guides it squarely onto the neck. This and other guide blocks provide downforce to help engage the threads.

The first pair of disks typically has no clutch. They are there to start the threads. Subsequent pairs, up to three, have adjustable clutches. These screw the cap down to the desired tightness or torque.

It is critical to rely on the clutches for cap torque control. Slippage of the disk on the cap can cause inconsistent torque, cap scuffing, excess disk wear, and particulates. These particulates can cling to the bottle and make for an unsightly bumpy appearance under the label.

It’s easy when you know!

Find out more about how spinning disk and other types of cappers work. It’s all in Chapter 5 of John Henry’s Packaging Machinery Handbook. Other chapters cover inspection, flexible packaging, coding, and all commonly used packaging machinery. The complete table of contents and chapter samples can be found at http://www.packmachbook.com/handbooksample.pdf.

Purchase the Handbook on Amazon at https://amzn.to/3kr4qj7.

About the Author(s)

You May Also Like