Considering a die-cut insert card for medical device protection, sustainability, and efficiency

January 13, 2016

Chuck Taylor’s packaging team at Medtronic is moving toward designs that support sustainability efforts and cost reductions. “We are trying to accomplish benefits for everyone in terms of usability and reducing waste on a weight basis in operating rooms,” he says. “We are also looking for solutions that can be recovered, reused, or recycled. There’s not a lot of [these programs] in hospitals, but we want to offer the opportunity.”

For one particular Advanced Energy product, they are considering five different packaging options instead of a rigid PETG tray with a lid: a flexible blister as well as four different pouch alternatives with different internal options such as a die-cut insert card and a thermoformed insert.

While sustainability and cost efficiency are priorities, so is product protection. “We want to make sure the device is functional,” says Taylor, who serves as principal packaging engineer in the Surgical Solutions Group located in Boulder, CO. “There are jaws on the end of the device, and while durability is built in, there is susceptibility to damage if nurses were to dump the device. And we need to protect it from any distribution hazards.”

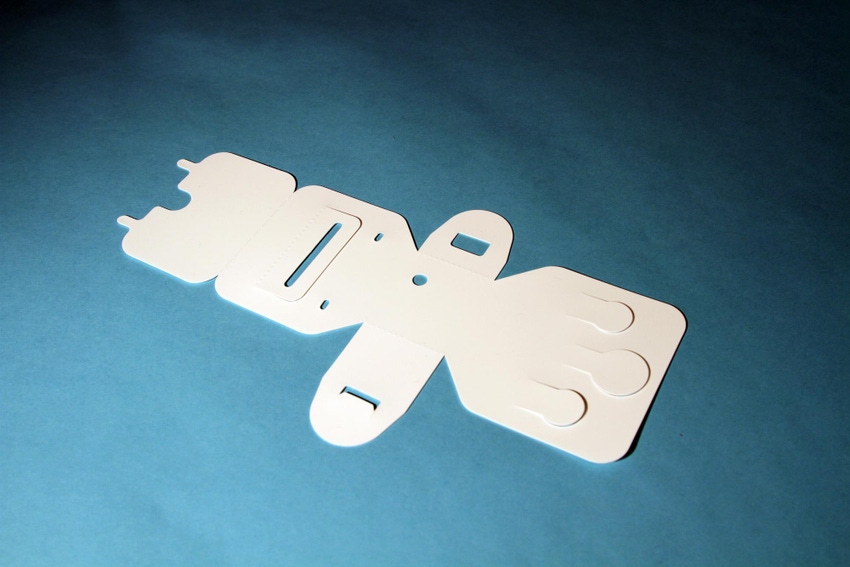

A die-cut insert card from Beacon Converters is under consideration, he says. “Most of our product lines don’t lend themselves to the insert, but this product was more applicable,” he says. “It presents an option to completely cover the jaws, and there is no chance that the device would come out of place.”

Also, the combination of a pouch and the die-cut insert—which can be made out of a monomer—“sufficiently reduces the weight going into the stream, reducing cost for us and for hospitals,” he says.

Taylor approached Beacon with a few main objectives, reports Kathleen Daly Mascolo, Vice President and Director of Sales and Marketing, for Beacon. “We have worked with Chuck previously, and he came to us with this opportunity. His main objectives were management of the 10-ft-long cord and protecting the jaws from abrasion and shock. Ergonomics, ease of getting the device on the card, efficiencies with manufacturing, and getting nurses’ feedback were also objectives.”

Beacon designed a die-cut insert card (DCIC) for use with an outer pouch. “The DCIC stabilized the product in the pouch, protecting the device from the pouch and the pouch from the device,” says Daly Mascolo.

She adds that the DCIC meets trends toward using flexible materials. In addition, “the DCIC is recyclable and serves as a cost-effective approach with reduced tooling and lead times,” she says. “It helps obtain a smaller footprint, and it offers manufacturing efficiencies while addressing ergonomic concerns.”

Taylor is also considering a thermoform with snap-in features to hold the jaw. But he recalls comments made by nurses at HealthPack expressing concern that products could come out of snap-ins, he says, and the DCIC seems to protect areas of concern, even during dumping.

“Extreme events do happen,” he says.

To help Taylor determine whether implementing the DCIC would meet user needs, he submitted five options to the HealthPack 2015 nurses panel for evaluation and discussion. “It is a small sample, and there is no specific protocol, but you get valuable feedback to take back to your teams,” Taylor says. “I like the voice of the customer.”

Taylor had actually submitted a different package to a previous nurses panel at HealthPack, he says. The team did take into consideration the nurses’ comments when making the decision.

The nurses at HealthPack 2015 appeared to favor the die-cut insert card, Taylor reports. All options will be further explored in a more-structured effort in terms of VOC, he adds.

Getting voice-of-the-customer input early on is ideal. “The best practice is getting involved in projects as early as possible in order to have the time and financial backing to get the voice of the customer before deciding,” he says. “Being early also allows you time to experiment and research.”

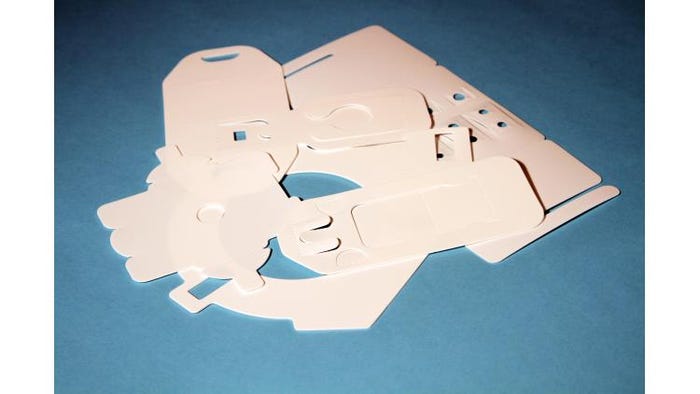

Other die-cut insert cards from Beacon Converters

Taylor hasn’t made a decision yet about the die-cut insert cards, so his team is examining the assembly process. “Fixtures may be needed for operators to place the card to facilitate assembly,” he says. The team is also looking at incorporating the insert into the cord assembly process. The cord is preassembled before the rest of the product assembly. “We would look at ways to reduce labor time and consider ergonomics. We may also have options for packaging upstream with the suppliers that process the subassemblies.”

Taylor adds that considering the die-cut insert card has enabled him to look at the entire process. “When you look at the whole system, you can look at other areas for product protection beyond packaging,” he says.

______________________________________________________________________________________________________________________

Focused on medical device packaging? Find medical packaging inspiration at MD&M West February 9-11 in Anaheim, CA.

_____________________________________________________________________________________________________________________

About the Author(s)

You May Also Like