Preparing for Quality Management System Regulation Amendments

All US manufacturers may have to conform to a new risk-based quality system regulation by 2026. But how should companies prepare for the change? Timothy Gooch lays down his recommendations.

December 29, 2023

.png?width=850&auto=webp&quality=95&format=jpg&disable=upscale)

To improve the overall safety and performance of medical devices, the United States FDA has proposed an amendment to the Code of Federal Regulations (CFR) for 21 CFR4 Part 820 of the current good manufacturing practice (CGMP) requirements, as a means to more closely align the agency’s medical device quality management system requirements to the international consensus standard for devices and used by other regulatory authorities.

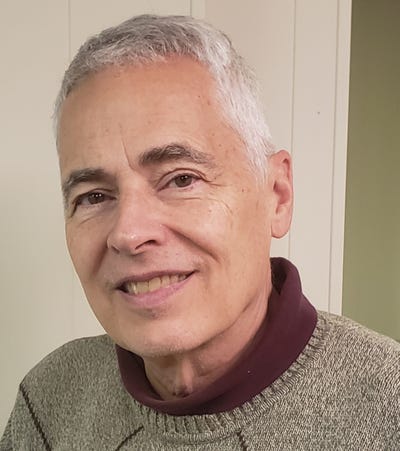

Timothy Gooch, technical director of life sciences management systems and supply chain at SGS North America, in Rutherford, NJ, will share how best to prepare and conform to the new quality management system regulation — scheduled to be published in 2024 with a two-year transition period — at MD&M West in Anaheim, CA, on Feb. 7 at 1:15 pm to 2pm in Room 203AB.

Before the upcoming conference, MD+DI caught up with Gooch for more information on the regulation and its potential challenges.

Why the proposed amendment?

Gooch: Most of the regulatory jurisdictions around the world already recognize the International Organization for Standardization (ISO) 13485 from 2016 as the current approach to the quality management system model.

The FDA has also participated in the Medical Device Single Audit Program (MDSAP) since its inception in 2015, with full acceptance in 2018. Hence, the FDA has become accustomed to manufacturers that already conform to the requirements of the standard ISO 13485.

Any entity that legally manufactures a medical device in the US will need to comply to the new requirements by 2026.

How much of a change is the proposed amendment to the current quality system regulation?

Gooch: The proposed amendment is geared more toward a risk-based model than the requirements of the current quality system regulations (21 CFR 820). In some ways, it may seem that the US is playing catch-up with the rest of the world, because FDA’s quality system regulation has not had a major update since 1996.

The changes are primarily how the ISO is constructed versus the way the quality system regulatory is constructed. The new amendment is more of a management system approach than a set of regulations and rules that need to be met by manufacturers. In essence, the onus of meeting the requirements is on the top management of manufacturers. The acceptability of risk for their devices is one of management’s largest responsibilities, according to ISO 13485.

This new iteration will be called a quality management system regulation as opposed to the formerly known quality system regulation. There will be much more of an emphasis on the management of quality system risk and device risk, whereas prior to this change the risk was primarily considered during the design phase of medical devices in the US. Now risk will apply to all facets of quality management, including product realization, human resources, design and development, purchasing, and the management of outsourcing processes.

Monitoring the post-manufacturing phase of any medical device for risk and feeding those risks back into the system for updates will also be mandatory.

Any challenges to implementing the changes?

Gooch: The greatest challenge will be for manufacturers to focus on the risk portion of ISO 13485 between now and when the regulation becomes law. Manufacturers need to look at the way they make risk-based decisions, how they collect data and how they manage non-conformances — both as they relate to product and to the system that manages the manufacturing and design of medical devices.

How can manufacturers overcome these challenges?

Gooch: For companies not already compliant, they can look at the audit model that is described in the MDSAP. The official document can be found on the FDA website, which takes manufacturers through a prescribed audit that meets all the requirements of ISO 13485, plus requirements for jurisdictions outside the US.

Overall, the FDA is asking manufacturers to focus on developing systems for the risk-based approach and that they build systems for monitoring measurement and improvement, and for quality planning.

About the Author(s)

You May Also Like