2 musts of cannabis packaging design

Increased legalization of cannabis in North America is creating a significant opportunity for packaging suppliers and designers. But to work effectively with cannabis brand owners, vendors need a solid understanding of the category’s special packaging requirements. Product freshness and package security top that list.

The new “The Future of Cannabis Packaging to 2024” report from Smithers explores these two key requirements and also discusses common package formats, the evolution of cannabis branding, the role of premium packaging and the growth of vape products.

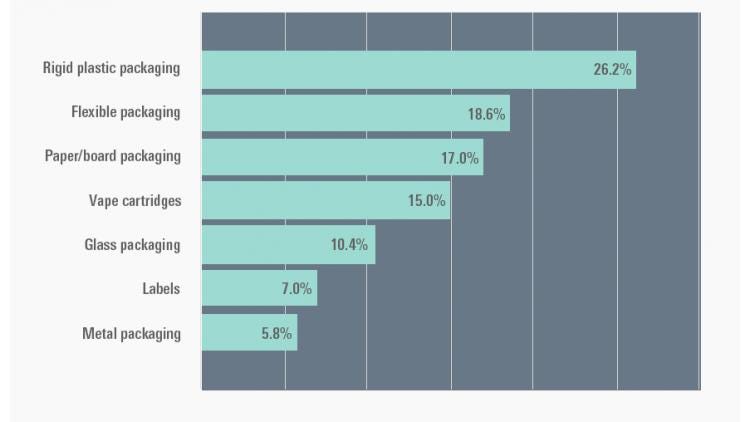

The Smithers report identifies different packaging formats used in the cannabis market.

Packaging that protects freshness is essential, Smithers explains, because light and oxygen can degrade cannabis and its active ingredients. Cannabis packaging must therefore include barriers to light and oxygen, preferably before and after the package has been opened. Repeatedly opening and closing a package allows the product’s moisture and volatile compounds to escape and lets oxygen in.

As an example of a package that protects cannabis cigarettes throughout the pack’s life cycle, including numerous openings/closings, Smithers references Honest Marijuana. This company sells flowers and pre-rolls in steel cans that contain a liquid nitrogen dosing unit which, over time, releases enough nitrogen into the package to keep residual oxygen at less than 4% (see image at top of page).

Protecting cannabis from oxygen is more important than protecting it from light, but packagers intent on ultraviolet (UV) protection can use opaque containers. Smithers points out, however, that opaque packaging has a downside: Many cannabis consumers prefer transparent packaging, which lets them see the product before purchasing.

Like other drugs, cannabis also requires secure packaging. Child-resistant features are essential for safe storage in the home, and a variety of child-resistant designs are currently in use. In many cases, package designers have borrowed child-resistant closure designs from other products.

“This includes screw tops for pill bottles from the pharmaceutical industry, zip-lock features used in pouch packaging and push-button features in carton packaging, previously used for nicotine replacement gums,” Smithers reports.

Security of a different kind is evident in cannabis track-and-trace systems that embrace the entire supply chain. According to Smithers, tracking the products ensures “seed-to-sale integrity” and gives consumers an assurance of product authenticity.

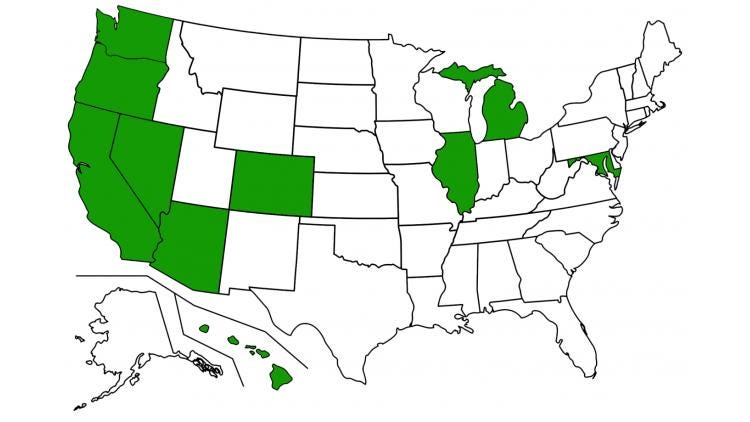

Most states in which medical and/or recreational cannabis is legal require dispensaries, cultivators and others in the industry to implement track-and-trace systems.

For more information about cannabis packaging, as well as networking opportunities within this quickly growing market niche, packaging professionals are invited to attend the upcoming Cannabis Packaging Summit. This event will debut at WestPack 2020 (Feb. 11-13; Anaheim, CA).

____________________________________________________________________________________________

Find your success! Subscribe to free Packaging Digest enewsletters.

Find your success! Subscribe to free Packaging Digest enewsletters.

About the Author(s)

You May Also Like