5 exciting, emerging sustainable packaging materials to watch in 2016

January 25, 2018

Year over year, advancements in technology that impact the packaging industry become more innovative, robust, widespread and tangible. The outcomes of these new technologies sometimes leave lasting impressions while others fade with trial and error.

In terms of safety and sustainability measures though, technological advancements and innovations often play dual roles that counter inhibiting circumstances and propel new opportunities. In these advancements, we find some of the latest and greatest in what proves the packaging industry to be one of the strongest fields in leading innovation, sustainability and safety.

While we know packaging is often viewed and used as a vehicle for marketing tactics, its most obvious and critical role is to protect its product. Food packaging maintains proper temperatures, prevents exposure to bacteria, communicates information to consumers and enables retailers to track and trace to the original source. Packaging also promotes sustainability, both by protecting and enhancing the shelf life of foods (thereby reducing food waste) and by encouraging recyclability at its end of life.

Committed to connecting innovation to opportunity, suppliers and innovators are continually working with technology providers to bring creative, sustainable packaging solutions to market that help consumer packaged goods manufacturers, retailers and foodservice providers enhance the safety of their products, drive sales and delight consumers.

Here are a handful of recent innovations on the bleeding edge. It is only a matter of time before these new technologies are not only brought to market but become highly influential in various and competing packaging industries:

1. Sustainable Aqueous Barrier Coatings

New sustainable coatings improve any fiber products (by preventing moisture from penetrating the material and potentially contaminating foods) and present alternatives to laminated structures that, in contrast to those treated with new sustainable coatings, cannot be recycled. In sustainable practices, this is a major differentiator factor of this new technology (see photo above).

Next: Molded Fiber Printing

******************************************************************************

Did you know? Our parent company UBM owns these popular packaging events: WestPack, EastPack, PackEx Toronto and PackEx Montreal. Click the links to learn how you can connect in person with leading packaging technology partners, expand your professional network, hear experts analyze key packaging trends and gain a better understanding of today's critical issues.

Visi-Top egg cartons from Huhtamaki can be printed on two sides—ample room to share product information and branding.

2. Molded Fiber Printing

New technology enables high-resolution four-color graphics to be applied directly on the surface of molded fiber packaging. Benefits include visually appealing graphics and better packaging sustainability (no need for additional outer packaging or wrap with a label on it) at a low per-unit cost and higher production rate with less barrier on time.

Next: Light Weight Insulation

******************************************************************************

Did you know? Our parent company UBM owns these popular packaging events: WestPack, EastPack, PackEx Toronto and PackEx Montreal. Click the links to learn how you can connect in person with leading packaging technology partners, expand your professional network, hear experts analyze key packaging trends and gain a better understanding of today's critical issues.

The insulation technology used in retail Chill Buddy products can be used in packaging applications.

3. Light Weight Insulation

Chill Buddy is a lightweight, durable insulation for hot or cold applications. The temperature-controlling packaging material offers clear advantages over conventional insulated blanket technology and is a flexible, sustainable alternative to expanded polystyrene (EPS) foam. Commercialized in Europe, retail stores leverage the new technology for shrouds over dolly, roll cages and pallets. These shrouds maintain chilled conditions for more than 3.5 hours—and are particularly useful in stores with limited space for refrigeration and when products have high turnover.

Next: Micro-Fibrillated Cellulose (MFC) Specialty Fiber

******************************************************************************

Did you know? Our parent company UBM owns these popular packaging events: WestPack, EastPack, PackEx Toronto and PackEx Montreal. Click the links to learn how you can connect in person with leading packaging technology partners, expand your professional network, hear experts analyze key packaging trends and gain a better understanding of today's critical issues.

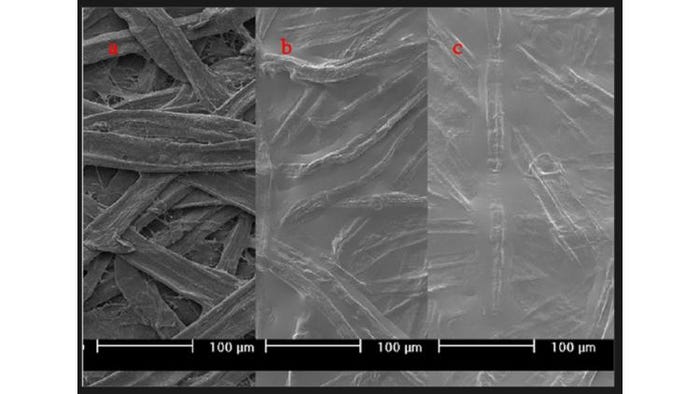

MFC coatings on paperboard: (a) reference paper; (b) 1 g/m 2 MFC coat; (c) 1.8 g/m 2 MFC coat. Source: Aulin, Gällstedt, et al. (2010).

4. Micro-Fibrillated Cellulose (MFC) Specialty Fiber

Micro-Fibrillated Cellulose (MFC) is a unique fiber extracted from plant waste, used to strengthen and lighten fiber products sustainably. Benefits from this technology include reduced material with maintained performance, a material stronger and stiffer than glass or carbon fiber (but lighter weight), improved crack resistance and efficient rheology aid. It also provides oxygen and moister barriers. You can significantly enhance product performance with minimal additions of the material to existing substrates. For example, 1% can result in a 15% to 20% product performance improvement. Since this derived from crops—not from trees—it provides a much more competitive price point than other micro-fibrillated cellulose products.

Next: Micro-Pattern Material Enhancement

******************************************************************************

Did you know? Our parent company UBM owns these popular packaging events: WestPack, EastPack, PackEx Toronto and PackEx Montreal. Click the links to learn how you can connect in person with leading packaging technology partners, expand your professional network, hear experts analyze key packaging trends and gain a better understanding of today's critical issues.

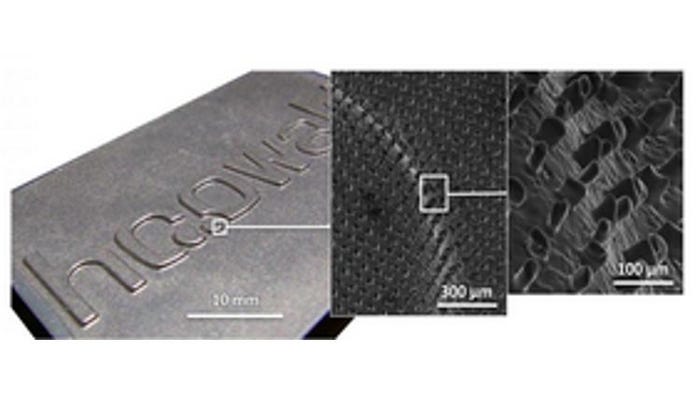

5. Micro-Pattern Material Enhancement

Emerging technology transforms the surfaces of cups with micro-patterning. Without having any impact on graphic presentation, this new technology from Hoowaki not only provides improved grip, comfort and handling of hot beverages, but slows the formation of condensation and improves material performance characteristics without changing or introducing new chemistry.

Demands from the market are requiring more and substantial advances in technology, leading to greater innovation on numerous levels. Through each of the above, there are not only elements of more sustainable packaging that we continue to see this increased demand for, but also more regulatory requirements forcing companies to consider new alternatives.

The rate of technology change continues to challenge the industry. To stay relevant and efficiently effective, implementing new and innovative technologies into products and packaging will become a norm and a constant, evolutionary process alongside the also evolving regulatory implications and restrictions.

With this, we see not only from the advancements in the examples above, but from the continued innovation in packaging across all spectrums, the industry will continue to perpetuate its own need for transformative design, function, operation and technology.

Shane Bertsch, vp of innovation at HAVI Global Solutions (HGS), drives innovation across the organization by constantly looking at customer and market needs and creating opportunity platforms based on business and technology trends. Prior to joining HGS, he held packaging roles at Abbott Laboratories, Unilever and Stone Container Corp. Bertsch has a Bachelor of Science degree in Packaging from Michigan State University and a Master of Engineering Management degree from Northwestern University.

******************************************************************************

Did you know? Our parent company UBM owns these popular packaging events: WestPack, EastPack, PackEx Toronto and PackEx Montreal. Click the links to learn how you can connect in person with leading packaging technology partners, expand your professional network, hear experts analyze key packaging trends and gain a better understanding of today's critical issues.

About the Author(s)

You May Also Like