Digital Inkjet Gives Small Brands a Big Boost

LSINC’s printing technology offers cost savings and a competitive advantage for brands with small production volumes and many SKUs.

At a Glance

- Digital inkjet direct-package printing is ideal for high-mix/low-volume decorating

- Compatible package shapes include cylindrical, conical/tapered, and contoured

- Faux embossing and tactile effects add to the premium presentation

A direct-package printing technology that combines the best of digital and inkjet printing is gaining traction, particularly among small brand owners that need low volumes of high-end, custom packaging for multiple stock-keeping units (SKUs).

The technology, from Huntsville, AL-based LSINC, enables production of premium-quality packaging while decreasing costs and waste, reducing turnaround time, enabling quick changeover, and improving efficiency vs. conventional package decorating and labeling methods.

LSINC’s helical, direct-to-object printing technology enables brand owners and packaging suppliers to print directly on bottles and cans, eliminating labels. The digital inkjet printers can decorate a portion of the package or the entire container, printing myriad packaging sizes, shapes, and materials on demand.

LSINC’s PeriQ360 and PeriOne printers can decorate cylindrical and tapered/conical packaging. Additionally, the Perivallo360m can print contoured surfaces, such as wine bottles. All three models feature Ricoh Gen4 Piezoelectric printheads.

PeriQ360 video shows tapered glasses being printed:

In addition to printing seamless, finely detailed images, the technology can be used for tactile, textural printing, and faux embossing. To create the look and feel of embossing, the equipment applies multiple layers of crystal-clear ink to the package to create raised patterns.

Enabling premium quality while cutting costs.

The ability to faux-emboss stock bottles with a variety of patterns, creating an array of unique packages, offers significant economies and a competitive advantage for small brand owners.

Instead of buying a minimum order — say, 20,000 — of several different custom bottles, the brand owner can buy the minimum quantity of one stock bottle and vary the faux embossing on the bottle to create a novel, luxe bottle design for each SKU.

This eliminates the cost of glass molds, typically needed to create custom bottles, as well as orders of unnecessarily high quantities of bottles. It also reduces overhead expenses such as warehousing, without sacrificing quality in the finished packaging.

The economics level the playing field for small brand owners, reducing barriers to entry and positioning them to compete with much larger companies. Of course, larger companies running lower volumes can enjoy the same benefits, too, though.

PeriQ360 video shows regular printing and faux embossing:

High-mix/low-volume packaging case study.

In quoting line speeds for its printers, LSINC references a 4-inch-high image rendered at “typical resolution,” says James Bullington, LSINC’s chief technology officer. “The PeriOne is a single-spindle printer for cylindrical and conical media with production rates up to 5 ppm,” printing one bottle or can at a time.

As an entry-level model, the PeriOne offers benefits for start-ups and brands transitioning from conventional decorating techniques to digital inkjet. Niagara Landing Wine Cellars, a family-owned business in New York state, switched to in-house bottle decorating with a PeriOne printer after Niagara’s screen-printing vendor closed its doors.

Niagara Landing using LSINC

With direct-package printing, Niagara Landing saves about 18 cents per bottle vs. screen-printed labels, based on raw materials and labor. It has also improved the quality of its bottle decoration, moving from one- or two-color labels to full-color bottle printing. In addition, the company can easily create special bottles for events and promotions using the new technology.

Another LSINC printer, the quad-spindle PeriQ360, prints four bottles or cans at the same time. With speeds up to 19 packages per minute, this model is suitable for light to medium production volumes. The PeriQ360 is equipped with the same technology as the PeriOne and, similarly, prints cylindrical and tapered/conical packaging.

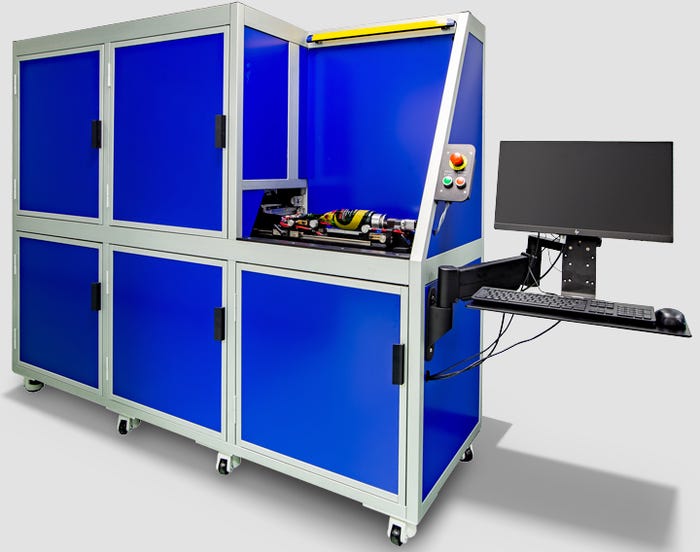

LSINC Perivallo360m

Completing the company’s lineup is the Perivallo360m, which prints contoured surfaces at speeds up to 4 ppm. A curvy beverage bottle, for example, can be decorated from heel to neck with smooth, continuous graphics and no die lines.

With all three models, package printing can be performed by the packaging supplier or at the brand owner’s facility, prior to filling. “Printing cells can be configured to feed the output from multiple printers to the filling line,” Bullington says. “Short runs with specialty effects are well suited to the speeds available.”

In fact, the technology’s flexibility makes it a good fit for low-volume direct-package printing of all kinds, including personalized packaging and promotional or limited-edition packs. The PeriOne is useful for quickly producing prototype packages, as well.

“A large sector of the [consumer packaged goods] industry is moving to mass customization for traceability and specialty marketing campaigns. Neither are well suited to traditional decoration techniques,” Bullington says. “Inkjet allows high-mix/low-volume solution sets.”

LSINC

Packaging applications for LSINC’s technology include wine, spirits, and other beverages; syrups and flavorings; cosmetics; candle jars; and pharmaceuticals.

The technology can be used to print on clear or colorless glass, metal (including aerosol cans), polyethylene terephthalate (PET), and wood, and packaging media can be automatically fed to the printer.

Inks, images, and color matching.

Each of the printers comes with up to seven colors, standard: cyan, magenta, yellow, and key/black (CMYK); white; primer; and varnish. Inks are stored in 3-Liter bulk tanks in the bottom of the machine.

LSINC has partnered with Marabu for the inks that run in its machines.

LSINC’s ecofriendly inks do not contaminate the glass-recycling process or produce volatiles dangerous to the environment; the volatiles in the inks dissipate at glass-recycling temperatures.

“On [clear PET], there could be some interference with recycling. PET and acrylic inks have a very similar specific gravity, and since most of the recycling of ground plastics is done in settling tanks after grinding, to float label material off, there is the possibility,” Bullington says.

To solve that problem, “there are specialized air beds that keep the ground media in suspension and which utilize optics and air nozzles to expel non-clear media and contaminants,” he adds. This equipment is recommended for recycling PET bottles printed with LSINC technology.

LSINC’s printers create images using digital process colors. “CMYK [inks] can achieve approximately 65% of the Pantone space,” Bullington says.

LSINC

Extended color sets, such as CMYKOG (CMYK plus orange and green) and CMYKcm (CMYK plus light cyan and light magenta), “provide a broader color gamut, achieving greater than 85% of the Pantone space,” he notes.

LSINC’s technology was on display at the Distilled Spirits Council of the United States (DISCUS) Annual Conference, March 4-6, 2024, in San Diego.

About the Author(s)

You May Also Like