Filling a niche 2378

January 29, 2014

By Daphne Allen, Editor, Pharmaceutical and Medical Packaging News

As pharma companies increase the number of products on their filling lines, quick changeover and careful monitoring become critical. Pharmaceutical companies are handling more products on single production lines these days, resulting in incredible demands on filling and

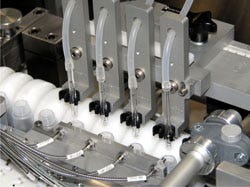

VP2 -Optima fillers.jpg

packaging lines. For some companies, smaller batches are the norm, challenging line operators to execute changeovers quickly and sufficiently. Machinery providers are keeping up, thankfully, offering a range of solutions.

"We are seeing requests to handle more products on one filling line, in smaller batches," explains Uwe Kellermann, vp of pharmaceutical applications, Optima Machinery Corp. "Pharmaceutical companies and contract manufacturing organizations are handling more products these days."

Similarly, Walter Langosch, director, sales and marketing, ESS Technologies Inc., has been fielding requests to build filling and handling machinery that can support multiple products. Such high turnover requires expeditious changeovers.

Disposable society

One of the biggest headaches in changing over from one product to another is cleaning. Not only does it take time and effort, but you have got to follow a validated process, so there can be no corner-cutting.

Unless you move toward disposable components. "There is a definite trend toward use of disposable pumps and tubing to eliminate the cleaning validations required. Coupled with CIP and SIP, disposables can cut turnaround time by 50 percent," says Kellermann.

Disposable nozzles, product bags and tubing are used with peristaltic filling technology, whose latest-generation systems can compete better with positive-displacement pump filling, Langosch says. "Peristaltic pumps are suited for disposables because the only components that touch the product are the nozzles and tubing. Changing the product ‘bag-in-box,' the tubing and nozzle takes only minutes. There is no risk of cross contamination," he says. But the tubing itself must be suitable for the product, while remaining malleable enough for the system to work properly, he adds.

At its first U.S. facility, contract manufacturer Vetter is using the new MHI 2020 B automated vial filler from Bosch Packaging Technology. Located at the Illinois Science + Technology Park in suburban Chicago, the 24,000-sq-ft site features three cleanrooms for aseptic filling and visual inspection (see in-depth article "Precision vial filling").

Minimizing contamination

Designed to handle clinical-stage, high-value biopharmaceuticals, Vetter's new automated vial filler can run up to 10,000 liquid or 6,000 lyophilized vials per batch. Employing a Restricted Access Barrier System (RABS), the system relies on automated filling and capping to mitigate risk of contamination by minimizing human intervention. It can run a range of fill volumes, from 0.1 to 23 ml, providing flexibility.

"Vetter's intention is to utilize only disposable liquid path technology for various reasons: reduce potential of contamination, eliminate cleaning process of product path and of cleaning validation, and ability to get to filling customers as quickly as possible," says David Cousins, director of sales, pharma liquid, Bosch Packaging Technology Inc., pharmaceutical operations.

"This is the first MHI 2020 B filler ca

VP1 - four up.jpg

pable of precise dosing (either through rolling-diaphragm or peristaltic pump dosing), stoppering and capping," he adds. "Vials move through the various stations via robotic handling, eliminating the potential for glass-to-glass contact during the filling operations."

Vetter's managing mirector Peter Soelkner explained in a statement: "Our Chicago facility provides customers with a top-of-the-line clinical manufacturing site located in the heart of the United States. Because Vetter consistently strives to stay at the forefront of innovation, securing Bosch's new fully automated vial filler was a natural for us."

Multiple filling technologies

Not every product is suitable for peristaltic pump filling, and users simply may want other options. Kellermann says that Optima fillers can be developed with options for more than one technology, such as rotary-piston pumps, time-pressure fill systems and peristaltic pumps.

"We have modified our systems to offer interchangeability," he explains. "Users can take the whole filling system out in one hour and change from peristaltic to time pressure, for instance."

Making the change within a RABS isn't as easy, however, he explains.

Optima has also made the filling station accessible from the back of the machine and added a transport and lift system for easy access. A roll-up module is also available to allow users to switch to peristaltic technology if needed, Kellermann explains.

ESS Technologies can also offer two filling or product delivery systems on one machine. "We can also add a servo-driven auger filler or even a tablet filler, if requested," Langosch says. When asked whether customers have sought equipment that can regularly switch from liquids to powders to tablets, he says "no, but theoretically it is possible."

ESS employs 100 percent net-weigh filling on its starwheel-based system. "As the container enters the starwheel, it travels over a cell to capture the tare, then moves through the filling station, then indexes to another weighing station to capture the fill weight," explains Langosch. "We designed the process to be extremely accurate and have added a feedback loop to allow pump adjustment on the fly."

Speed limitations

Because of the intermittent motion, there are speed limitations, and smaller volumes typically mean faster speeds. But the number of weigh cells can be doubled to increase throughput.

Accuracy, however, can be a time saver. "You can greatly reduce the rework or scrap by addressing issues inline before containers leave the machine, and that's where our feedback loop comes in," Langosch adds.

Optima begins its monitoring with net-weigh filling, switches to in-process control and then back to net weighing. Such sequencing enables Optima to minimize product waste during priming, which can be a concern for high-value biologicals, says Kellermann.

Optima systems also monitor seal force/torque, as well as stopper pressure and crimping in-process.

ESS uses product and component detection systems throughout filling and assembly, Langosch reports. "We can verify that the pump has triggered and cycled, and we can then detect streams and placement of stoppers, caps and overcaps."

ESS recently developed servo torque technology for th

V3 - Monobloc.jpg

e final torque at a second station. "It allows customers to customize the final torque needed, and our in-process monitoring allows us to track the torque of every cap," he adds.

Time matters

Langosch reports that changeover time convinced one customer to opt for ESS equipment. "One customer picked our HMI-controlled system with 10-minute changeover over a system with a 20-minute changeover. The HMI controls all servo-driven functions, which include nozzle diving, filling, capping and torquing."

Ten minutes may not sound like a much of deal maker, unless you hear Langosch's explanation: "If one shift has three changeovers, you save 30 minutes per shift. If you only run one-shift per day, 250 days per year, you save enough time to run 15 extra days of production."

Bosch Packaging Technology Inc., 763-424-4700. www.boschpharma-us.com

ESS Technologies Inc., 540-961-5716. www.esstechnologies.com

Optima Machinery Corp., 920-339-2222. www.optima-usa.com

About the Author(s)

You May Also Like