How to Execute Excellence in Packaging Development Time After Time

Using a packaging development Center of Excellence as a model for managing a packaging department can help you achieve fast growth and boost profits.

As sustainability and cost drivers pressure packaging departments to deliver more value, greater agility, and faster speed to market, establishing a Packaging Development Center of Excellence provides a platform that enables your team to deliver successful, repeatable results. A well run PackDev CoE accelerates future competitiveness and enables faster growth and enhanced profits. It aligns the entire packaging department to execute its strategy and deliver against its goals.

With a PackDev CoE in place, a brand can expect its packaging department to not only be more efficient, but also more accurate. It also provides the packaging department with the tools to optimize costs and the flexibility to evolve to meet new challenges.

What is a PackDev CoE?

A PackDev CoE is a model for managing a packaging department. The model focuses on strong and well aligned fundamental concepts that are common to many successful organizations:

People — enabling cognitive ability and promoting productive interpersonal interactions.

Processes — Aligned to enable efficiency.

Systems — Leveraging computer power to unburden teams.

Implementing a well-run CoE enables an organization to drive consistent, forecastable value from its packaging operations. It makes the people, processes, and systems in place fundamentally stronger and aligns them to execute against the packaging department’s goals.

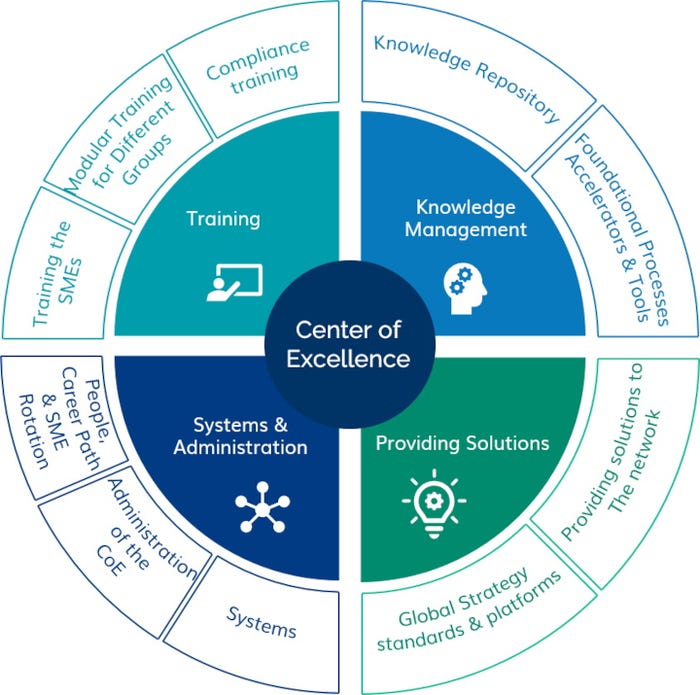

The Adept Group model for a PackDev CoE contains four key components:

1. Providing Solutions.

2. Knowledge Management.

3. Team Development.

4. Systems & Governance.

Let’s take a look at each of these.

1. Providing Solutions.

To put things in the simplest terms possible, Providing Solutions is the execution of packaging development initiatives. This is the part of the model that is easiest to observe because it involves the packaging department’s output — the work it does on a day-to-day basis.

This process addresses the basic ways in which the packaging department supports the organization as whole through a strategy strongly aligned with the brand’s overall strategy. It leads to the development of platforms that can be implemented at scale while maintaining high standards that can be followed throughout the department. These platforms are geared toward sourcing and implementing the best packaging components, technologies, and practices.

Once those platforms are in place, the CoE provides opportunities to continually improve upon packaging practices to establish and maintain competitive advantage. This base business support creates a stable packaging operation that delivers optimized value to the entire organization.

This same process can also be geared toward providing ad-hoc, need-based solutions. It helps to assess incoming needs based on their organizational impact and their priority among the department’s and the organization’s overall needs. As business conditions change, a packaging department organized under a CoE model can develop individual solutions to new challenges and drive agile implementation of those solutions. All of this is done in a way that manages risk to the organization.

2. Knowledge Management.

Knowledge Management focuses on how the packaging department can make the best use of institutional knowledge and convert new learnings into lasting knowledge that can be implemented and shared throughout the department.

A key component of Knowledge Management is, of course, the creation of knowledge. The process is based on developing knowledge that enhances the competitive advantage a CoE provides. The platforms and methodology that support Providing Solutions are continually honed and improved upon by the accumulation and implementation of knowledge that allows the department to work faster, more accurately, and at a lower cost.

The other key component of Knowledge Management is the development of a repository through which that knowledge can be shared, managed, and used in a standardized way across the packaging department. In practical terms, this repository is stored and shared through software platforms and training programs that form the backbone of Knowledge Management.

3. Team Development.

Team Development is the care, support, and development of a packaging department’s most valuable assets — its people. This is accomplished through three key elements, the first of which is team building. Team building allows a department to both hire and maintain top talent that drives its success. It also involves a strategy for resourcing and provides tools for workload management that keeps talent happy and provides personnel with opportunities to make meaningful contributions to the organization.

The second element is an efficient training program that elevates the department and contributes to a competitive advantage. The most efficient training programs take a modular approach that groups individual trainings into distinct curriculums for different groups, based on their primary functions. These trainings can focus broadly on the functions of the CoE that governs the department or on more specific topics such as emerging technology — think sustainability or advanced track-and-trace solutions — or ongoing compliance needs.

The third element of Knowledge Management is the development of subject matter experts (SMEs) within the department. Perhaps the highest value a CoE can produce, and certainly the end goal of Team Development, is a roster of true SMEs whose knowledge enhances the output of the packaging department. Recognizing and nurturing SMEs is a key component of retaining the talent a CoE creates.

4. Systems & Governance.

Systems & Governance is the key component that organizes all other components of a CoE, which makes it crucial that this component is executed correctly. Without a good system for managing the CoE, it is not practical to sustain the model over the long term.

A key element of Systems & Governance is an organized system of leadership at all team levels, strong culture that drives job satisfaction within the department, and a defined set of career paths that guide achievement throughout the department.

Another key element is the administration of the CoE, including setting and adhering to well-planned budgets and setting aggressive, but achievable goals for the department and its team members.

The third element of Systems & Governance is the management of data and software that enhance the functionality of a packaging department. Examples of data include packaging specs and project management info and other details that need to be tracked and stored in an organized way for easy access. Examples of software systems include a specification management system, the training system, and software tools that enable workload management.

By developing a Center of Excellence, you can optimize how your packaging operations function and enhance the value of your packaging to the company’s business.

About the Author(s)

You May Also Like