Single-source success

A new single-source integrated packaging line

is providing big benefits for Barr Laboratories' solid-dosage tablet and capsule plant in Forest, VA. Installed a year ago, the 100-bottle-per-minute line runs all 10 bottle sizes (30- to 1,500-cc capacity) and all 60 products packaged at the plant. "With its tool-less changeover capabilities, this equipment is ideal for all of the different packages we run," says associate director of packaging Chris Baker.

Headquartered in Pomoma, NY, Barr Laboratories is a specialty pharmaceutical company that develops, manufactures and markets generic and proprietary prescription pharmaceutical products.

Most of the equipment on the Forest line was manufactured by NJM/CLI, which was also the systems integrator. "We went to NJM/CLI because we wanted the Cremer electronic tablet fillers, and they are represented by NJM/CLI here in the United States and Canada. We also have some NJM/CLI labelers on our other lines, and we've been very pleased with them," says Baker.

Machines are equipped with Siemens and/or Allen-Bradley PLCs, and the line integration includes sensors installed at critical points to stop the bottle conveyors in case of backups.

Except for some inspection systems, NJM/CLI installed the complete line, including non-NJM/CLI equipment, in its manufacturing plant in Montreal, where debugging and acceptance testing took place. "We sent all of our different bottles up there for the testing, and went there ourselves for the factory acceptance test of the line. We also sent some of our key people up there to become familiar with the equipment and become our in-house experts," says Baker.

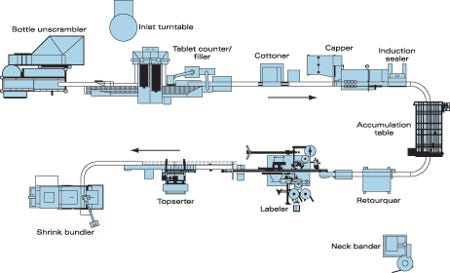

Runs 100 bottles per minute

Plastic bottles are delivered to the line in paperboard boxes, and an operator dumps them into a hopper, where they enter a Unisort 300 unscrambler manufactured by Pace Packaging Corp. The bottles discharge from the hopper onto a conveyor transporting them past a series of wheels and belts that turns them to the proper position. The unit at Barr Labs is equipped with an optional ionized air rinse with a concurrent vacuum. Bottles are placed in an inverted position so that the air can be blown upward into them, and any solids will fall out. The bottles are turned into an upright position before they leave the machine.

The bottles then travel to a Model CF-1220-D dual-head electronic tablet filler manufactured by Cremer Packaging Technology. NJM/CLI represents Cremer in North America. Normally, the unit has two heads, and bottles are split into lanes as they enter the machine, so that each head serves one lane. However, because the line was running a test product during PD's visit, the unit was operating just one of the existing two heads. Each head has 12 individual V-shaped tracks, for a total of 24 tracks. The machine also is available in a 48-track "Quad" configuration, for greater output.

Each head is equipped with a hopper that delivers the tablets to the 12-lane vibrating trays where they are single-filed. The machine has three trays in series, each set at a slightly faster vibration rate, to optimize tablet separation for counting.

Tablets discharge from the 12 channels on the vibrating tray into the scanning unit, where they fall through individual light beams that count them into a closed chute. When the required preprogrammed quantity has accumulated, flaps engage to hold back incoming tablets, while the counted tablets drop into the bottle on the conveyor below.

|

Capper incorporates four sets of of horizontal discs in series to tighten the caps, and two sets of air clutches for torque control. A cap inspection system after the machine checks for skewed or missing caps and missing foil liners. |

The machine is controlled through a proprietary PC developed by Cremer. Users store operating parameters for each product, such as tablet count and size, which are accessed through a touchscreen terminal. The state-of-the-art electronic controls provide complete diagnostic capabilities and fault detection with help screens, as well as the capability to print production reports and perform statistical analysis.

Bottles leaving the filler pass beneath an empty bottle detector from Keyence Corp. of America that emits a pulsing laser beam down into the bottle to measure the height of tablets in the bottle. This unit was installed by Barr Labs after the line was installed.

From the filler, bottles travel to an NJM/CLI Model CL-110 cottoner that features two-station cotton insertion to ensure that the cotton is securely inserted into the bottle. The machine stops automatically when there is no cotton or high cotton, and incorporates a photocell for container and cotton detection.

Capping comes next with an NJM/CLI Model Unicap 150 automatic capper running through a PLC. Caps are fed to the machine through a chute connected to a waterfall-style sorter. As caps travel from the elevator to the capper, they pass by airjets that blow misoriented caps back into the hopper. The unit incorporates four sets of horizontal discs in series to tighten the caps, and two individual sets of air clutches for torque control. A cap inspection system after the machine checks for skewed or missing caps and missing foil liners.

Model Unicap 150 automatic capper running through a PLC. Caps are fed to the machine through a chute connected to a waterfall-style sorter. As caps travel from the elevator to the capper, they pass by airjets that blow misoriented caps back into the hopper. The unit incorporates four sets of horizontal discs in series to tighten the caps, and two individual sets of air clutches for torque control. A cap inspection system after the machine checks for skewed or missing caps and missing foil liners.

Immediately following the capper is an Enercon Compak solid-state induction sealer that seals the cap's inner foil liner to the bottle rim. The conveyor after the induction sealer makes a right-angle turn, and bottles pass an accumulation table that enables the line to keep running during short downstream stoppages, such as changing rollstock on the labeler.

The conveyor makes another right turn, and bottles enter a Unicap-150 automatic retorquer from NJM/CLI that tights caps that have loosened during induction sealing. The unit is based on the same design as the capper.

Although it has not yet been installed, NJM/CLI supplied a Model M-5 AutoCapsealer shrink-banding machine from Marburg Industries as part of this line. The shrink bander is mounted on its own stand, and NJM/CLI provided space on the conveyor so that it can be moved into place when needed. The shrink tunnel for the unit is already installed.

|

P-s labeler has label dispensing heads on both sides. One side applies labels, while the other side applies outserts, although both sides can present labels to bottles as well. Outserts are fed from a magazine onto a web of double-sided tape that travels the same path as the web of labels. |

Coded bottles then advance to an NJM/CLI Model 326 Auto-Colt III pressure-sensitive label applicator that has label dispensing heads on both sides. One side applies labels, while the other side applies outserts, although both sides can present labels to bottles as well. The roll of labels is mounted horizontally, and the web travels past dancer rolls to the application point, where the label is peeled off of the backing and applied to the passing bottle. The web is then rewound onto a cardboard core. Outserts are fed from a magazine onto a web of double-sided transfer tape that travels a similar route on the other side of the labeler, and applies the outserts to the bottle.

Bottles then travel through a Thiele machine that applies topserts to the tops of the caps of bottles passing below. Topserts are placed in an inclined magazine on the top of the machine, and suction cups on a rotary arm pick them up. Hot-melt glue is applied to the caps by a Nordson unit as the bottles enter the machine, after which the rotary arm applies the topserts.

Labels, outserts and topserts are preprinted at the label supplier with data matrix codes corresponding to the product. Lot number and expiration are printed on each label by a Norwood hot-stamp printer before the label is applied to the bottle.

The labeling, outserting and topserting operation incorporates an Integrated Inspection System by Calia Technical, Inc. (CTI). The system includes a four-camera vision inspection system based on the Visionscape Optical Character Verification System from RVSI Acuity. Three cameras are installed on the labeler. One verifies the lot number and expiration date; the other two verify the correctness of the data matrix code on the label and outsert.

The fourth camera is mounted on the topsert placer, which is downstream of the labeler. This camera verifies the correctness of topsert data matrix codes. The operator enters the products to be run into the control system, and all of the cameras must verify that their respective elements are present and correct, or the bottle is rejected.

|

A separate machine applies topserts to the tops of bottles passing below. The labeling, outserting and topserting operation incorporates a four-camera inspection system. Three cameras are installed on the labeler, while the fourth is installed on the topserter. |

In addition to vision inspection, the CTI system includes front and back ultraviolet sensors from Datalogic to check that labels have been applied to the bottles. The system also detects jams in the labeler and self-monitors all functions to ensure that all systems are working properly.

A human machine interface (HMI) program, developed by CTI, presents the status of the system, along with alarm and statistics, in a highly graphic format. The HMI also provides online schematics and live PLC ladder logic to facilitate system maintenance. Machine mimic-displays provide immediate graphic presentation of the machine and system status along with the pass/fail status of each label and outsert.

After labeling, bottles are conveyed to a shrink bundler from Omega Design Corp.

"NJM/CLI did an excellent job for us on this project. Installation and startup went very smoothly, and the line has run very well right from the beginning," says Baker.

More information is available:

Line integration, conveyors, cottoner, cap sorter, capper, retorquer, labeler; representative for unscrambler, filler: NJM/CLI, 800/432-2990. Circle No. 246.

Unscrambler: Pace Packaging, 800/867-2726. Circle No. 247.

Counter/filler: Cremer North America, 514/630-6990. Circle No. 248.

Empty bottle detector: Keyence Corp. of America, 201/930-0100. Circle No. 249.

PLCs: Allen-Bradley, 414/382-2000. Circle No. 250.

PLCs: Siemens Energy & Automation, 800/964-4114. Circle No. 251.

Induction sealer: Enercon Industries Corp., 262/255-6070. Circle No. 252.

Shrink bander: Marburg Industries, 760/727-3762. Circle No. 253.

UV scanner: Datalogic, Inc., 800/626-3993. Circle No. 254.

Topserter: Thiele Technologies, 612/782-1200. Circle No. 255.

Glue application: Nordson Marking Systems, 630/968-0646. Circle No. 256.

Hot-stamp printer: Norwood Corp., 770 /497-3715. Circle No. 257.

Label inspection: Calia Technology, Inc., 718/967-9757. Circle No. 258.

Vision software: RVSI Acuity CiMatrix, 330/609-7582. Circle No. 259.

Shrink bundler: Omega Design Corp., 610/363-6555. Circle No. 260.

About the Author(s)

You May Also Like