March 11, 2015

|

|

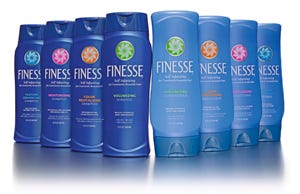

The Finesse® haircare line is back with new packaging and revved-up product formulations.

A stylish redesign for the line, which relaunched in spring of 2009, is certainly taking hold, cleaning up in sales, according to figures from the first national store chain that took the new products, which posted double-digit sales increases.

Originally, Finesse was introduced by Helene Curtis in the early 1980s as a single, oil-free, self-adjusting conditioner for women 35 to 55, who may typically want more hair conditioning to guard against dryness, brittleness and the rigors of color treatments.

A bit like today, the decade of Big Hair was also a time of economic stress, and many women gave up salon visits to cut costs and care for their hair at home. The distinctive scent of Finesse, which many loyal users still remember today, and the conditioner's effectiveness, helped to make it an immediate success. Finesse soon expanded to include shampoo and styling products and became a dominant brand in the retail haircare market.

The original line's heyday lasted for years and went up and down in favor, as the economy improved and women returned to salons. But during that time, scads of other haircare products launched, and captured the eye of consumers.

Unilever then bought the line in 1996 through its acquisition of Helene Curtis, and changed both the packaging and the product formulation. But the brand somehow couldn't keep pace with the changing haircare market.

When U.K.-based Lornamead purchased the brand in 2006 with the specific intention of reviving Finesse, the company planned to draw on the brand's key strengths and on the memories of users to draw them back, as well as give the product and its packaging 21st-century appeal to attract a new generation. The relaunch also has new formulations, but they're executed in a scent reminiscent of that in the original 1980s product.

In 2007, the company put the updated products onto retail shelves but they were still in the Unilever packaging. So Lornamead turned to bottle molder/designer Silgan Plastics Corp. to help develop new container designs and engaged Little Big Brands to create new branding and label graphics that would collectively project a dramatic new look and feeling. Silgan extrusion/blown-molds four shampoo and four conditioner bottles serving different hair types and a 13-oz HDPE bottles for a pair of two-in-one shampoo/conditioner combination products. A larger 24-oz family size bottle using the same package design is also available. Styling products, including maximum-hold hairspray, volumizing mousse and extra-hold hairspray, come in 7- and 8.5-oz aerosol and nonaerosol containers.

Custom look at stock prices

“Our primary goal was to make the brand contemporary and eye-catching, and the packaging premium, giving it the impact of custom packaging,” points out Karen Murabito, Lornamead group brand director. “But, given the current economy, we were also determined to control costs and maintain an affordable price point for consumers.”

The distinctive 1980s bottle featured a slim design with a flared foot and silver graphics. The new structure would require close interaction between the decision makers at Lornamead and the Creative Services Group at Silgan. Silgan used 3-dimensional computer imaging and fused deposition modeling (FDM), which gave the two groups a better idea of what the final bottle would look like, says Silgan's Creative Services group manager Stephen Kocis (see related article on p. 54).

The designs began with three-dimensional drawings, Kocis explains, and early on, Silgan developed 3D, FDM models for its own use.

An FDM printer operates much like an ink-jet printer, except that the “printhead” deposits plastic material instead of ink, Silgan explains. Container models can be created in the printer's build area, and multiple models can be created at the same time. Models can be solid, hollow with a controllable wall thickness (which can mimic closely a finished bottle) or hollow with an internal honeycomb structure for strength (typically done with larger models).

Finalizing designs

As the designs became more finalized, the FDM models were used in presentations to Lornamead.

Kocis initially visited Lornamead's offices in person to present early designs and gather input. From that point on, the designs were exchanged electronically until the FDM models were created and represented agreed-upon final versions. Kocis recalls that Creative Services began its design process by creating 3D CAD (Computer-Aided Designs) transmitted electronically utilizing E-Drawing software manipulated onscreen. This allowed the Silgan designers and Lornamead to both see packages from any angle and Lornamead wouldn't have to install any extra software. The designers could then continue to refine the design, saving both time and money and cutting the time to market for the new products.

|

|

“Designs typically progress through multiple iterations,” Kocis adds. “Being able to make new FDM models quickly and cost-effectively is essential today.”

The resulting bottles have a curvy, easy-grip oval shape, wide shoulders and large caps that complement the bottle shape so they can be used with two different bottle sizes. The caps provide bottle display both upright and in an inverted position. While the original bottle had a rounded shoulder and a small disc-top closure, Lornamead specified a wide, flat flip-cap for the new bottle, which would reduce clogging and could allow the structure to easily stand inverted.

Rapid prototyping

Silgan has three FDM Dimension printers made by Stratasys Inc., which also supplies the plastic used to model the prototypes. Creative Services makes an average of 900 models a year. FDM modeling was particularly important to the new Finesse project to achieve just the right physical shape of the bottle, Kocis says.

Silgan molds the bottles at its Ottawa, OH, facility. Silgan also provides a stock HDPE bottle for one of the styling products. The styling items include litho-printed steel cans from Crown Cork & Seal and aluminum cans that are dry-offset-printed by CCL Container.

Keeping the equity, not the cost

To keep costs in check, the same bottle shape is used upright for the shampoo as for the inverted conditioner. It was also decided, following cost comparisons, to use a stock closure supplied by Arminak Associates rather than invest in two custom designs when the result was virtually the same.

Lornamead also wanted the new bottle to be lightweight and meet sustainability requirements. Lightweighting was achieved by lessening the fill (13 oz versus the previous 15 oz) and by switching to a monolayer HDPE construction instead of the former multilayer HDPE structure.

Icon simplified

Label graphics on the earlier Finesse bottles had been somewhat costly and difficult to print, points out John Nunziato, creative director of Little Big Brands. “Three different printing processes were used to achieve the final result on the different container substrates.”

The original graphics, in Nunziato's words “had intricate layers and overlapping elements,” and required multiple printing passes to lay down as many as six colors for one icon. “We wanted to keep the brand equity of the original icon, but not the cost” explains Pamela Long, Little Big Brands director of client services.

The brand icon was simplified to maintain the effect of motion associated with the brand's original pinwheel-shaped icon that conveyed how the products can spin to consistently keep hair beautiful.

The result is color coded according to product SKU and printed in a two-step process on pressure-sensitive polyolefin label stock. National Label Co. screen-prints the logo in white type and in four-color process plus silver.

The trickiest part of the printing, Nunziato points out, was matching the exact color pinwheel with the color of the product identifier on the label. The logo was printed over a white background and the product identifier wasn't, so the identifier had to be printed directly on the transparent label film to appear as a slightly different color on the dark blue shampoo bottle than on the lighter blue conditioner bottle.

Different printing plates were made, and the color of the identifier was varied to match both HDPE bottle colors. The colors also had to be tweaked on the aluminum and steel cans to make them consistent across the entire line. The bottles are filled, labeled, cased-packed and shipped by Marietta Corp.

Less is more

Lornamead was able to get the new Finesse line on store shelves looking fresh and contemporary, at a reasonable cost, by cutting down on the print colors, using stock components and lightweighting the bottle.

The FDM technology also played a handsome role in submitting suitable container designs quickly.

Murabito notes that Lornamead is extremely pleased with the new Finesse packaging, especially with the impact of its early sales figures. The new packaging began rolling out in the first quarter of 2009 to stores across the U.S., including Walgreens, Target and Walmart, among others.

“This gives us evidence that the new packaging is going to make a dramatic difference in sales,” she says.

More information is available: |

Silgan Plastics Corp., 800/274-5426. www.silganplastics.com. |

Arminak Associates Inc., 626/358-4804. www.arminak-associates.com. |

CCL Container, 724/981-4420. www.cclcontainer.com. |

Crown Holdings, Inc. 215/698-5100. www.crowncork.com. |

Little Big Brands, 845/480-5911. www.littlebigbrands.com. |

Marietta Corp., 607/753-6746. www.mariettacorp.com. |

National Label Co., 610/825-3250. www.nationallabel.com. |

Stratasys Inc, 800/937-3010. www.stratasys.com. |

About the Author(s)

You May Also Like