One-piece CR closure eases application and opening

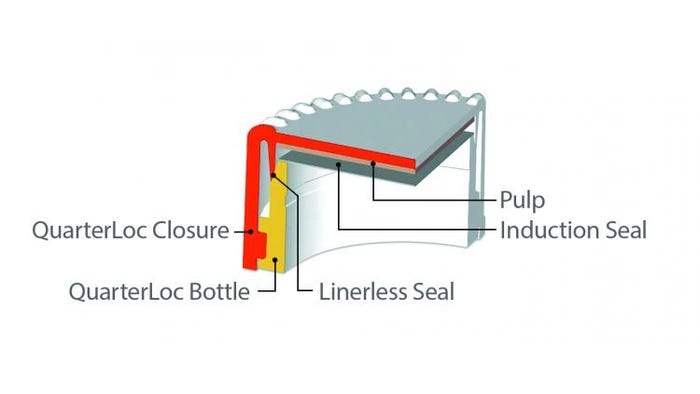

Two-piece push-and-turn child-resistant (CR) closures are notorious for being hard to open and reclose, causing user frustration, as well as potential cocked caps during application on the packaging line. The new SecureCap QuarterLoc one-piece closure solves those issues, while also reducing material weight by at least 25% and production time/costs by eliminating a second piece along with any assembly.

Developed by Comar, the polypropylene SecureCap QuarterLoc is a single molded part that requires just a quarter turn to apply and/or to open. This severely reduces the potential for mis-alignment and/or cocked caps, helping to eliminate user aggravation. The new closure passed Consumer Product Safety Commission testing protocols for child resistance and senior-friendly performance, and is suitable for a variety of over-the-counter pharmaceutical or nutraceutical products.

SecureCap QuarterLoc closure easily integrates into existing packaging lines, and can be adapted and scaled for different products. Because of the linerless design, brand owners do not need liners, but they can use standard foil induction liners or inline conduction liners if they choose. Softer ribs on the closure skirt make it more comfortable for consumers to handle. Audible and tactile closing adds a measure of security for users.

Sue Benigni, Comar’s business segment director for Consumer Healthcare, answers Packaging Digest’s questions about the new product.

What held back development of a single-piece push-and-turn CR closure in the past or why is this development do-able now?

Benigni: Single-piece CR closures have been available in the pharmacy in a design with open pockets on the sides for amber vials. The Quarterloc is manufactured using Comar proprietary molding technology, which allows solid sides for a more robust, secure and familiar look.

What were the Consumer Product Safety Commission (CPSC) child-resistant/senior-friendly test results of this new closure?

Benigni: Comar’s 625cc Round Pet Bottle/53mm SecureCap QuarterLoc Neck Finish Consumer Product Safety Report meets standards for poison prevention packaging evaluation per current C.F.R. Title 16, Part 1700.02. The package performed well for senior adults and children.

Why is it important that the closure is opened and closed with just a quarter turn?

Benigni: The quarter turn eliminates thread mis-alignment, cocked caps and the possibility of incomplete application. The reduced rotational distance to achieve a positive closure is also a benefit to seniors, especially those with reduced dexterity.

Does the quarter turn design also simplify closure application on the packaging line? If so, how?

Benigni: Yes. The application of the QuarterLoc closure requires only a quarter turn to apply and eliminates the potential of mis-aligned threads and cocked caps. The package is not torque dependent—there are no application or removal torque requirements. There is also no thread back-off after application.

Are modifications to the capper needed? Why or why not?

Benigni: Based on conversations and trials with several capping equipment manufacturers, the capping equipment must be capable of handling the closure size. And requirements for change parts are consistent with the change to a new closure.

There is no maximum torque requirement—10 to 15 inch-pounds is sufficient for application.

If an induction seal is required, down force is required at the time of seal activation.

Do bottle neck threads need to be redesigned to accommodate this closure?

Benigni: Yes, a custom bayonet-style thread is required. The closure’s design accommodates the growing trend toward square bottles because it allows for perfect alignment every time.

Does Comar also supply the PET bottles?

Benigni: Yes, the QuarterLoc is offered as a complete packaging system.

It is available in just one size, 53mm, correct? Any other sizes expected in the future?

Benigni: Currently, 53mm is available. A complete family of sizes are under development and will be prioritized based on market demand.

How much has the closure weight been reduced and how?

Benigni: Part is 25% to 35% lighter (unlined) than an equivalent two-piece push-and-turn CRC.

How much less expensive is this single-piece closure and compared to what?

Benigni: Cost savings are dependent upon several factors that are proprietary, but one can do the math on the material costs alone.

How much faster is production of this one-piece closure versus a comparable two-piece one?

Benigni: The manufacture eliminates the assembly step of mating the inner and outer components of a two-piece closure.

What did you do to make the side ribs softer?

Benigni: We increased the width and depth.

Is the linerless-seal part of the closure’s design, even if using a liner?

Benigni: The closure is not designed for use with liquids. However, the system meets USP 671 Tight Container Integrity requirements. Liner use is optional.

Any customization (color, top graphics or paper/foam liners) is an added cost, correct?

Benigni: Yes, as with any existing closure. But the molds are designed to accommodate customization at a modest cost.

How has market reaction been to this new closure?

Benigni: Reaction has been very positive from leading brands and retailers that value sustainability and cost savings.

Are any pharmaceutical or nutraceutical companies using this closure yet?

Benigni: Production quantities have just been made available. Customers are confidential for now, but will be on the market soon.

About the Author(s)

You May Also Like