Spirits Leader Sazerac Revolutionizes Packaging Inspection

The Sazerac Company’s CT scanning inspection that assesses glass bottles and other packaging components in minutes versus weeks is available to other companies.

October 21, 2020

Who can claim that a visit to the dentist resulted in a major, positive impact on a brand’s quality assurance processes?

An employee of spirits brand owner The Sazerac Company had such a eureka moment.

That happenstance along with subsequent research within the field of metrology inspection led to the company adapting computerized tomography (CT) technology to address its packaging engineering needs.

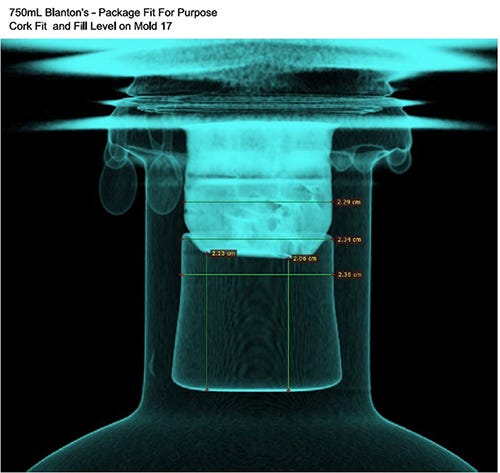

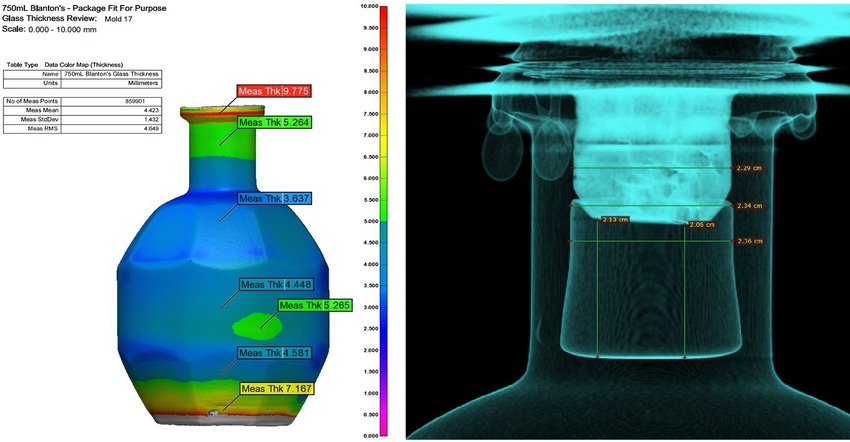

CT is trusted within the medical field to provide high-level detail using X-ray technology to assist doctors in making accurate and informed decisions. Sazerac is benefiting in a similar way by implementing the use of a CT scanner paired with trusted engineering software. With a portfolio of more than 450 brands, the 200-year-old company claims combining the two entities provides a powerful tool with measurement and vision capabilities far beyond the industry’s current state. In fact, Sazerac calls it “a revolutionary method to assess and measure packaging, components, and assemblies.”

How revolutionary? The time to appropriately identify an opportunity or issue has been reduced from weeks or longer is now done in minutes.

Alex Hagedorn, PhD, senior packaging engineer (left), and Terry Marfleet, VP procurement & contract manufacturing operations, who jointly developed the system shown between them, address Packaging Digest’s questions.

Describe the setup and process.

Sazerac: The system comprising a CT Scanner and PC are located in a laboratory. This concise setup eliminates the need of multiple pieces of equipment.

The two dissimilar systems, scanner and software, are plug-and-play and interface nicely.

The software configures the CT scan into workable 2D or 3D output which allows for component interactions (bottles/closures) to be seen and measured. Additionally, the software allows for comparisons to be overlaid and measured.

How is it used and what does it do?

Sazerac: The system can be used in the design phase comparing current to proposed as well as to root cause quality issues and/or machine setup struggles on-line. The system has shown success throughout the manufacturing and filling process.

The ability to dissect packaging without ever opening or destroying it physically, overlay multiple designs, cross-section, measure and incorporate Geometric Dimensioning and Tolerancing (GD&T) and physically see interactions to assess material quality and machine setup are now possible with speed and accuracy using one system.

How much of this was off-the-shelf and what was customized?

Sazerac: The scanner is common to the medical/dental industry. Custom fixturing transposes its use from humans to packaging and components.

Engineering software is common to the aviation/auto industry. Combining engineering software with a CT scanner results in a powerful tool for the spirits industry.

How long has this been in development?

Sazerac: Significant research into existing equipment used and outputs obtained was conducted, as well as an in-depth study of metrology and inspection. Feasibility and precision testing moved quickly. The complete system was available and in place and ready to use in 30 days.

What's the range of containers and defects that can be detected?

Sazerac: The system doesn’t have limitations to size that we’ve encountered, however common use thus far has been on components and bottles ranging from 50mL to 1.75L.

Uses include identifying thin material, material distribution, fit for purpose vision and measurement to quickly define if material, set-up, or both are compliant and within specification. This is the first nondestructive system allowing user to interact, measure, cut, slice—without opening the bottle.

How was this done in the past?

Sazerac: Previous approach relied heavily on vendor to take individual components and analyze with the many tools.

In what ways is this better?

Sazerac: The new system is built and driven by two simple principles, truth and speed. The previous approach was time consuming and failed to consider the system of components and how the two reacted or complimented one another.

The days of laboriously dissecting various forms of packaging to obtain basic measurements are gone, as is the use of comparators, calipers, and other equipment. At best, the results obtained from these time and equipment intensive traditional methods were costly and incomplete.

How fast is it?

Sazerac: A complete analysis of component, bottle, or both including digitally slicing, measuring, and seeing component interaction, and conducting material overlays can be conducted in 30 minutes.

Can you quantify how much the system reduces line stoppages or increases uptime?

Sazerac: The time to appropriately identify an opportunity or issue has been reduced from weeks, months, or longer to minutes.

The speed of the machine and ability to analyze all packaging components together quickly provides the complete answers to make sound decisions.

What is the projected return-on-investment?

Sazerac: The system provides immediate results. Depending on severity, ROI could be immediate through detection of components not fit for purpose.

Who operates the system?

Sazerac: Trained packaging engineers utilize and maintain the system.

What was the biggest challenge?

Sazerac: Since implementation, the system continues to solve difficult challenges. Seeing the fitment of a closure applied to a bottle and how threads engage with the finish is amazing, as well as measuring, cutting, slicing without ever cutting the bottle or utilizing an additional tool — and if desired can determine headspace, cork compression, etc.

|

Any surprise during development?

Sazerac: It was unchartered territory of shooting a bottle and closure system with a CT scanner. Considering this novel approach and partnering it with engineering software which immediately provided the answers was sought. It worked! The quality, resolution, heatmapping of thickness and ability to identify differences is now possible.

What safety precautions are needed?

Sazerac: As with any CT scanner, the unit should be qualified and registered. Placement and use should be verified. Adequate training should occur as well as routine maintenance.

What’s the current usage status? And what's the next step?

Sazerac: One system supports all plants with results provided faster and more accurate than ever before.

Immediate plan is to use the system for gold standard development of design and material optimization. That said of course, a couple really great additions in play to further change the industry—those to be disclosed at a later time.

Would the company consider licensing or partnering with other companies to market the technology?

Sazerac: The intent is that the industry will adopt the concept to revolutionize current practices to accelerate the improvement of quality, customer satisfaction, and reduce cost by defining with truth and speed.

Final thoughts?

Sazerac: The trusted system used in the medical/dental industry provides answers quickly while considering the entire system—allowing for fit for purpose packaging design, which is a definite advancement to the industry.

For further information, contact Alex Hagedorn, [email protected], 502-269-2826; or Terry Marfleet, [email protected], 502-815-2415.

You May Also Like