The Importance of Metal Detector Verification and Validation

Properly verifying and validating the metal detection equipment on your packaging line can help you achieve the ultimate goal: ensuring product safety for consumers.

The packaging industry demands that products meet Hazard Analysis Critical Control Points (HACCP), Food Safety Modernization Act (FSMA), and Global Food Safety Initiative (GFSI). Government guidelines drive companies to create policies, procedures, and protocols to ensure product safety.

Product purity must be monitored from the time the product enters the plant until the time it leaves the shipping department. Continual data logging is imperative for corrective action and auditing purposes.

That’s why metal detector verification and validation are essential processes for ensuring your equipment is operating within your packaging safety programs’ requirements. When these crucial steps are ignored or handled incorrectly, the result could be non-compliance and allowing product impurities to go unnoticed. Both scenarios are detrimental for a company.

To give you basic understanding and guidance, let’s explore verification and validation that can be done for any metal detector.

Defining terms.

What is verification and validation?

• Verification is the act or process of proving that the metal detector meets its sensitivity requirements. This is accomplished by challenging the detector in a repeatable manner with a certified metal sphere at a pre-described time. Most often, this procedure is executed at the same time on a daily basis.

A correct test procedure requires the certified sphere to be placed on or in the product. This is especially important as some products may impact the detectability of certain metals, especially stainless steel. This is often overlooked as many operators simply place the metal test piece in or through the aperture without the product. For most third party audits, testing without product will result in non-compliance and, even worse, could allow metal to pass undetected during production.

Certified test pieces, as shown in the photo, are readily available and should include a certification number that corresponds to a certificate of compliance. The certificate confirms the sphere size and metal composition, and is essential to a comprehensive food safety program.

• Validation is the process of authenticating the metal detector, ensuring the equipment is meeting the verification requirements. For instance, if your metal detector has been verified to detect a 2mm stainless sphere, a processor would validate these results (typically annually) using a third party. Companies that validate equipment should provide the user with documentation in the form of a certification letter and sticker that is conspicuously located on the equipment.

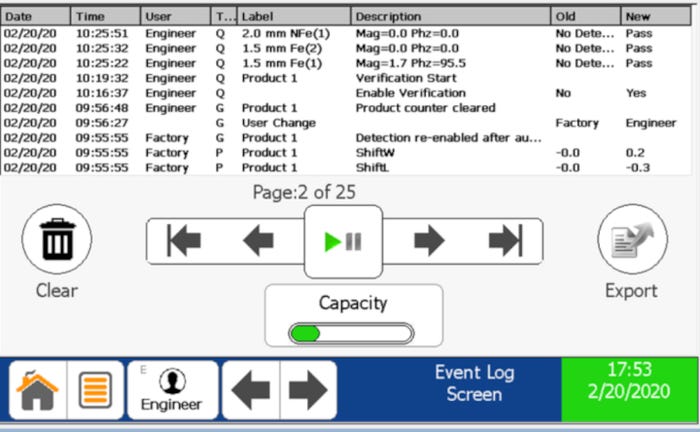

Documentation is not limited to just the third-party validations. A sound program must also include record-keeping. In other words, it is not enough to say you are verifying your equipment, you must prove you are doing this. Record-keeping varies by manufacturer. For example, some metal detectors, like the Eriez Xtreme, keep an event log, as shown in this image:

Understand the importance of verification and validation.

Investing in a metal detector can safeguard against machinery damage, production downtime, and loss of product quality. In many operations, metal detectors are the last line of defense for detection of contaminants. Considering the importance placed on this equipment, it is easy to understand the heavy compliance standards surrounding the operation of this equipment in packaging applications.

Understanding and properly performing verification and validation processes will ensure your metal detector complies with your packaging safety program, as well as other global regulations, including Food Safety Modernization Act (FSMA), Global Food Safety Initiative (GFSI), and current regulated Hazard Analysis Critical Control Points (HACCP) requirements. Ultimately, verification and validation processes for metal detectors play a significant role in keeping consumers safe.

A Step-by-Step Look at Verification

Step-by-step screen shots — taken from an Eriez Xtreme metal detector unit — give you a sense of how to perform a typical verification process. Watch the slideshow to see the six steps.

About the Author(s)

You May Also Like