Filler gets a grip on accuracy

Founded in 1932, Xttrium Laboratories, Mt. Prospect, IL, is o

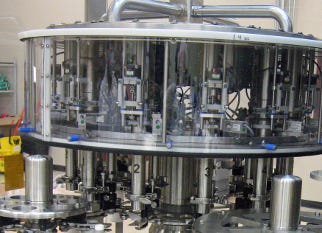

rrrrr1-filler overall.jpg

ne of the largest U.S. suppliers of FDA-approved 2 and 4 percent chlorhexidine gluconate (CHG) formulations. These are antimicrobials for surgical scrubbing and health care personnel hand washing. Recognized as an industry leader in this infection control category, Xttrium has established contract manufacturing partnerships with many of the recognized brands and market leaders in the U.S. healthcare industry.Xttrium opened a new 106,000-sq-ft facility earlier this year, and it installed two new monobloc filler/cappers from Serac Inc. this summer-a basic model RB machine that essentially is dedicated to running a single bottle size and Serac's new model FC machine on which Xttrium runs bottle sizes ranging from 4 to 32 fl oz. Xttrium executive vp Madeleine Creevy says, "We have talked to Serac for years, and we like their machines. Also, they are located close to us, which is an additional benefit. When our operations director started looking for a monobloc machine for a dedicated line, they were the company we talked to.

"We also needed a new machine for a multi-product line we were planning, so we ended up ordering both the base machine and their new Model FC machine. We installed the base machine in June and the Model FC machine in July."

The completely new Model FC machine has a number of design features that Creevy likes. She mentioned the tankless design in which product is pumped directly from a storage tank to the filler nozzles without passing through an intermediate tank on the filler. Creavy says, "This cuts cleaning time in half and there are no [CIP] spray balls."

The FC machine incorporates Serac's new universal transfer claw that holds the bottles by the neck. The system can handle neck diameter ranging from 25 to 45mm and 35 to 60mm and bottles of almost any height without requiring a change of tooling. Xttrium runs four bottles sizes without any changeover.

The machine was designed with the operator and maintenance personnel in mind. All m

rrrrr2 - Filler - filling.jpg

achine components are mounted above the floor and are enclosed by large sliding doors that provide total visibility and accessibility. The operator has complete overview and access to the machine. Maintenance personnel can work on all components of the machine at eye level. The control cabinet is mounted on the machine instead of the wall, which eliminates external wiring and cable runs and provides easy operator access.

Clamps hold bottles

Bottles are sorted in a Model AU-6C unscrambler from Kaps-All Packaging Systems. Bottles from a rotary feeder pass through unit that stand them up on the conveyor. A feedscrew at the inlet of the Serac Model F12C6/720 monobloc filler/capper indexes the bottles into a starwheel that contains the clamps described previously that grip the bottles by the neck. The turret transfers the bottles to clamps on the filler turret that hold the bottles beneath the fill nozzles as it revolves.

The system incorporates a new valve design that uses magnets to position the fill nozzle. In this technology, magnets are positioned inside and outside of the nozzle cylinder. The inner magnet is attached to the fill valve and a vertical screw on the outside of the housing moves the outer magnet up or down. This "drags" the inside magnet with the attached fill valve up or down, thus placing the valve in the proper position. The screw is driven by a stepper motor, which gives it precise control.

Serac's patented Dynaflow technology is also incorporated into this new filler, to achieve extreme accuracy, while optimizing the filling time based on the product specifications. The Dynaflow can be thought of as a smart flow-meter that controls and adjusts the flow of product based on how much weight is filled into the container during a filling period. The filling accuracy is not affected by any variation of product temperature or viscosity, and it allows direct connection from the process piping to the filling valves. This eliminates the need for a hold tank on the filler, simplifying the cleaning process.

In addition to handling the net weight calculations, the computer-based control system on the filler records processing and filling data for every bottle run and provides statistical p

rrrr3 - filler closeup.jpg

roduction feedback. It will present a statistical fill-weight average and standard deviation for any period of production selected, monitor the tare weight of incoming bottles, alert the operator if a bottle is outside of the acceptable weight range, list the number of under-fills and over-fills with the cause of each and monitor run times. It will also reject bottles that do not contain the correct weight of product.

Six-head capper

After filling, the bottles are transferred through a separate turret into the Serac MTC 6-head mechanical capper. Caps are dumped into a floor hopper and lifted into the overhead hopper, which has a rotating disk inside. Caps fall into cavities in the disk and discharge into the cap track leading down into the capper. If the caps entering the track are not in the required "open top down" orientation, a jet of air blows them out of the cavity, and they go through the process again.

Caps travel down the track from the hopper into the capper, where they are picked up by jaws on the individual capping heads. To minimize cap damage and provide optimum gripping, the head is not rotating when it picks up the cap. The capping head starts turning when the cap is engaging the bottle.

Like the filler, the capper also uses contiguous inner and outer magnets, in this case to provide the clutching action and apply the torque to the cap.

The system raises and lowers the outer magnet, which is driven, and as it descends, more surface is opposite the inner magnet so more force is applied

rrrr4 - inkjet.jpg

. To further minimize cap damage, the pressure on the jaws is released and the jaws open as soon as the set amount of torque is reached.

On this monobloc machine, all operations are controlled by the computer. When changing from one product to another, the operator only has to select the new product from a menu in the computer, and the PC will set the filling and operating parameters automatically.

A sensor on the machine detects bottles with no caps and rejects them.

Bottles leaving the capper are conveyed past a Markem-Imaje inkjet printer that applies a lot number and expiration date to the shoulder of the bottle. It continues to a Series 3 Premier pressure-sensitive labeler from Tronics America that applies a 3/4-wrap booklet label supplied by Platinum Press Inc.

The Series3 uses a small onboard re-writable processor chip located inside the control panel that includes all of the software needed to run the unit regardless of its configuration. This makes field upgrades a snap because all that is needed to activate the software is to flip a dipswitch inside the touch panel from the "off" to the "on" position. Downloading proprietary software from a laptop is not required.

Instead of an HMI menu-based LCD display, the labeler uses a simple touch pad. This allows the operator to make changes on the fly without diving through various menu screens. Examples of this would include changing the machine speed. All motors on the machine are synchronized with the conveyor and ramp up and down together.

In addition, modules can be adjusted independent of the overall machine spe

rrrr5 - Labeler.jpg

ed, such as slowing down the label head so it dispenses the label slower than the product is traveling down the conveyor allowing the label to stretch across a contoured surface, ideal for clear labels. This feature helps to eliminate bubbles when applying labels. The operator can recall up to 100 previously stored jobs to expedite setup.

Miscellaneous features include batch counting with integrated signal, real time products/min display, count of total products labeled, inputs and outputs for missing or low labels and PLC connectivity with upstream and downstream equipment.

Tamper-evident shrink bands

The bottles then travel to a Tripack Model MSA-180 shrink sleeve applicator that applies a vertically perforated, tamper-evident shrink band around the cap and down past the shoulder of the bottle. In this operation, a motorized roller on the back of the machine pulls the film off of the roll. It travels up and over the top of the machine and comes down over a mandrel.

Two motorized feed wheels at the top of the mandrel pull the film down, and a series of rotating blades located around the mandrel cut off the section of film that is then pushed down over the bottles by another set of motorized application wheels. A sensor at the bottle infeed conveyor detects bottles as they enter the machine and initiates each operating cycle.

The machine features an operator touchscreen and the PLC remembers the operating parameters for different packages so that they can be recalled at a touch from the operator.

The bottles travel through a steam tunnel to shrink the band tightly and continue to a rotating accumulation table. Workers manually pack the bottles into shippers, which are taped shut by a Bestpack Packaging Systems top-sealing machine.

Bottles are supplied by Ashland Container Corp., Hub Plastics Inc. and WB Bottle Supply Co. Caps are supplied by Zeller Plastik USA Inc.

Ashland Container Corp., 708-758-8800. www.ashlandcontainer.com

Bestpack Packaging Systems, 888-588-2378. www.bestpack.com

Hub Plastics Inc., 614-861-1791. www.hubplastics.com

Kaps-All Packaging Systems, 631-727-0300. www.kapsall.com

Markem-Imaje, 866-263-4644. www.markem-imaje.com

Platinum Press Inc., 469-733-1506. www.platinumpress.com

Serac Inc., 630-510-9343. www.serac-group.com

Tripack, 866-900-1255. www.tripack.net

Tronics America, 866-465-3415. www.tronicsamerica.com

WB Bottle Supply Co., 800-738-3931. www.wbbottle.com

Zeller Plastik USA Inc., 847-247-7900. www.zelleramericas.com

About the Author(s)

You May Also Like