March 11, 2015

Vision inspection can offer a 'see' of solutions

Brand owners and packagers know that an imperfect package carries a negative message about their brand into the marketplace. Something as simple as a cocked label can change a consumer's perception of a company, and alter a purchasing decision-perhaps forever. And, since the first complaint is to the retailer, that relationship may be irreparably harmed as well.

As a result, most companies have established inspection regimens to spot and reject damaged and defective packages, such as those not completely filled or with wrinkled labels and cocked caps, before they go out the door.

In a high-speed manufacturing or packaging environment, a machine vision solution can perform tirelessly, communicate instantly with production line controls and adapt immediately to changeovers in inspection targets, making it an effective tool able to pay for itself quickly by reducing both labor costs and the liability costs associated with product recalls.

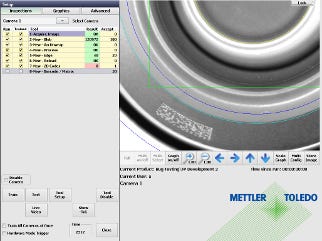

A vision inspection solution brings together cameras, lighting and image processing software to create an installation that is able to "see" objects and inspect them for flaws at high speed and with great accuracy. The heart of the solution is the computer software—the brain that processes what the camera captures and evaluates it by comparing it to a memory of stored ideal images.

Today's vision inspection solutions are designed to quickly, cost-effectively and accurately count items, compare them with ideal standards, measure them precisely and read and confirm codes and markings. One significant benefit these solutions offer is that the user is isolated from the technology: operators interface with the solution's software through an human-machine interface (HMI) that allows them to choose the relevant inspection target from a menu and press "Run" without the need to understand or directly interact with the solution's PLC or the complex algorithms it uses to complete the inspection. This isolation also greatly reduces the opportunity for human error.

What can it do for you?

In addition to inspecting products and packaging, a machine vision system can also verify alpha/numeric codes, bar codes and data matrix images. On a packaging line, the system can verify the correctness of incoming materials and then ensure that the right product gets into the right package and the right case, with correct labeling. Working from electronic order data, it can also ensure that pallet loads are correct before they go out the door to be shipped to a customer.

In addition to greater accuracy in inspections and the resulting improvement in product reaching the marketplace, a vision inspection solution can communicate with the owner's enterprise system, updating production, inventory and maintenance data. The system reports the number of defects detected and, if these exceed a pre-determined threshold, it automatically shuts down the production line for adjustments.

The levels of efficiency and automation in a vision inspection system depends on what the customer needs and decides to invest. Competing systems on the market offer varying features. A system can be designed to include all of the features described above, and to also automatically adjust to line changeovers by simply viewing a new package or by reading bar code data from the day's production schedule run sheet. The solution software will then automatically adjust camera positions and conveyor speed and make any other necessary system changes to accommodate the new product being inspected.

Is vision expensive?

A machine vision system requires an initial capital investment, like any new equipment. That initial cost depends on the complexity of the system. This includes the number of cameras and lights, the kind of lenses, the number of servomotors available to quickly adjust the system to inspect larger and smaller targets, and the size of the conveyor carrying products through the inspection area.

As with any other investment in machinery or control systems, "cost" must be distinguished from "value." An evaluation of any machine or system considering monetary outlay alone will result in a misleading conclusion. Purchasers of vision inspection solutions need to consider a variety of factors. What is included in the system? Will electrical cabinets and mounting brackets be additional, or included in the system cost? Will additional investment be needed to rearrange the production line? Does the prospective system allow for easy expansion to additional lines, or for simple in-house programming for any new products to be inspected? Does the manufacturer offer technical support for any future expansion?

In addition, cost savings offsetting the investment need to be incorporated into the evaluation. Will the number of line operators or inspectors be reduced, and those people (and their cost) transferred to another area? Will automated inspection enable the line to increase productivity? And, most often overlooked: What is the financial value to the company of reducing or eliminating recalls, customer complaints and even potential lawsuits resulting from defective or mislabeled packaging reaching store shelves?

Once considered a luxury only affordable by large companies, machine vision solutions have become both more sophisticated and more available, and their cost has fallen at the same time that the value they deliver has risen.

However, proliferation has also meant that the market offers a range of systems for the buyer to evaluate. A company that is considering a machine vision inspection solution needs to evaluate not only the capability of the equipment set but the completeness of the power supply and control system, the adaptability of the system to modification, the technical support offered by the manufacturer and the reputation of the maker.

Return on investment Implementing an effective vision inspection program can offer a quick return on investment (ROI) that is primarily affected by three factors:

1.Reduced staff to visually inspect product;

2.Fewer product recalls or returns;

3.Eliminated retailer fines for delivering defective product.

Savings in the value of reduced staff involves a simple calculation for ROI. Avoiding fines and reducing the number of product recalls, on the other hand, is more difficult to estimate accurately. In some facilities these are frequent occurrences and in others they rarely happen. As a result, these intangibles often don't get considered when calculating ROI for a vision system. However, these critical gains not only offer the potential for financial benefit; they also offer the positive gain of enhancing your company's reputation.

Vision inspection can offer a ‘see’ of solutions

The vision advantageMost vision inspection solutions are simple to operate and maintain. Once a new system has been installed and adjusted to specific customer needs, it requires minimal maintenance, and can easily be operated by existing line operators.

A reputable provider of vision inspection solutions will include operator training with its equipment. Purchasers also should ensure that the solution they buy includes technical assistance after the system is installed, tested and commissioned.

Many of today's less sophisticated vision inspection solutions do not offer the ability to automate inspection changeovers, which limits them to performing on dedicated lines. Brand owners and contract packagers whose lines package a variety of products should be sure that the solution they choose does enable automated changeovers, because time-consuming manual changeovers will quickly eat into the labor-saving advantage of having a vision inspection solution.

Purchasers of vision inspection solutions also need to be aware that rapidly changing technology may leave them behind. As you evaluate the solution you are considering, evaluate the company that stands behind it as well.

This article was written by Scott Stone, marketing director, Mettler-Toledo CI-Vision. For more information, visit www.mt.com/ci-vision.

About the Author(s)

You May Also Like