Accurate filling directly benefits a product’s profitability. Because you don’t want to give away product for free if you can help it. And you can, with a checkweigher.

January 12, 2023

Product weight is a key parameter for accurate filling. For example, for some drug products, over or underweight can affect the dosage. For other products, you want to guarantee that the customer is getting what they pay for — without giving too much away for free.

Inline checkweighers weigh every package. Products under the target weight are automatically rejected. Products over the target weight may be rejected or accepted. Depending on how much and how frequently they are out of spec, an alarm may sound or the line may be stopped when the weights are off.

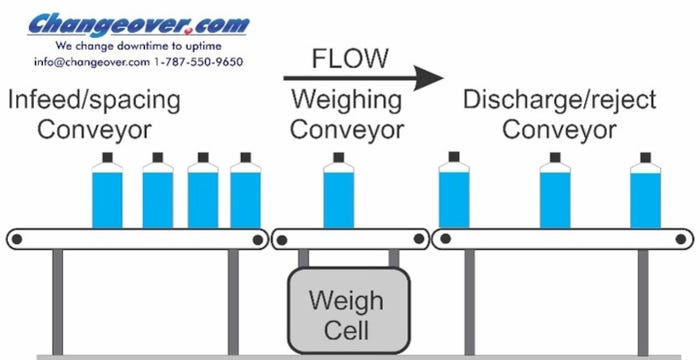

The typical checkweigher consists of three conveyors and a load or weigh cell.

The infeed conveyor is used to meter product into the weighing conveyor. Speed differentials assure that only one package will be on the weighing conveyor at a time.

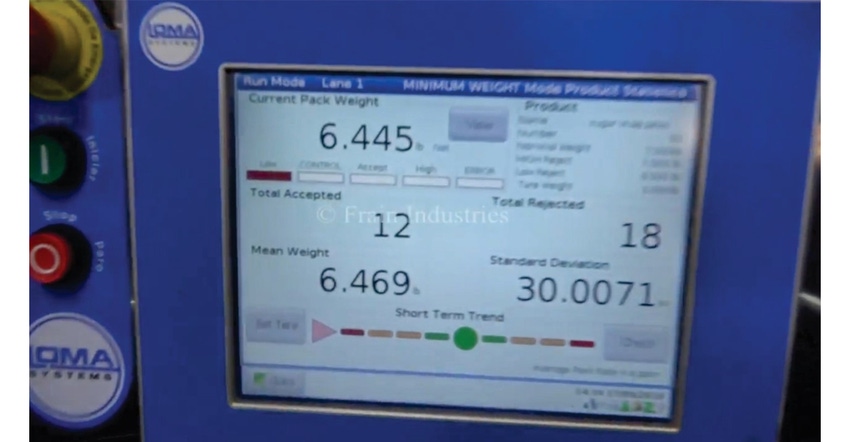

The central conveyor is mounted on a weigh cell. Sensors detect the presence of a package and record the weight. The weight is compared to the target. If it’s outside acceptable limits, a reject or alarm system is activated. Statistical data — such as averages, standard deviations speeds, and trends — are recorded and displayed on a screen or exported to an Enterprise Resource Planning (ERP) system. Some systems provide real-time feedback to the filler for continuous adjustment to ensure accurate weight.

The third conveyor includes the reject devices. Out-of-spec product is tracked from the weigh cell and rejected so it doesn’t leave the plant. Good product passes through for subsequent packing and shipping.

Some products — like chicken parts — do not have a precise target weight. Rather than being rejected, products are weighed, and the weight is printed on a label or directly on the package, often along with price.

It’s easy when you know.

Find out more about checkweighing and other inspection machinery. It’s all in Chapter 3 of my Packaging Machinery Handbook. Other chapters cover filling, flexible packaging, coding, and all commonly used packaging machinery. The complete table of contents and chapter samples can be found at http://www.packmachbook.com/handbooksample.pdf.

Purchase the Handbook on Amazon at https://amzn.to/3kr4qj7.

About the Author(s)

You May Also Like