A redesigned chocolate moose

January 29, 2014

|

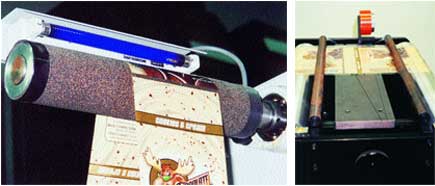

The Chocolate Moose shrink sleeve labels exit the 11-color gravure press and travel to the viewing station for inspection. |

The moose is back, and he's hipper than ever. North American Beverage, Inc. relaunched its Chocolate Moose Premium chocolate milk line with a redesigned moose logo–including updated sunglasses–sporting a new six-color, full-body shrink sleeve. The nationally distributed chocolate milk line includes flavors such as Original Chocolate, Diet White Chocolate, and a new flavor, Cookies & Cream.

The New Jersey beverage maker introduced the premium chocolate milk line in '93 and originally used a 360-deg wraparound label. However, the company recognized the attractive qualities of full-body labels in '98 and introduced them for its Havana Cappuccino line.

Now, North American Beverage utilizes full-body shrink sleeves for its Havana Iced Cappuccino and Chocolate Moose lines. With previous experience and success with shrink sleeves, the company's marketing firm, Roar Marketing Group, felt the increased amount of label space could offer a more refined visual concept. Ben Stone, partner at Roar Marketing Group says, "Shrink sleeves provide such a huge palette to work from, and we felt the product's shelf impact could really benefit from a larger design concept. We integrated not only an updated moose logo, but also included background swirls, product splashes, cream-filled chocolate cookies and white chocolate pieces to dramatically increase each flavor's product appetite appeal."

|

The Cookies & Cream shrink-sleeve label is printed in six-colors with one special color–metallic gold. |

SleeveCo, Inc. supplies and prints the shrink sleeves on an 11-color, 800-ft/min Chesnut 150 gravure press, from W.R. Chesnut Engineering. The sleeve is printed in six colors with a special metallic gold for all three flavors. Klöckner Pentaplast of America provides the 2-mil clear polyvinyl chloride film.

A shelf-stable moose

In the mid-'90s, Dean's Chug bottles led the way in single-serve dairy beverage products with full-body shrink sleeves. From that, beverage companies saw an opportunity to explore different product offerings in the dairy Ready-To-Drink (RTD) category. John Imbesi, president of North American Beverage, brought the Chocolate Moose line to market in '93, but differentiated the product line by making it shelf-stable. According to Imbesi, cooler space is as valuable to the beverage retailer as prime property in midtown Manhattan, and a shelf-stable product avoids that hurdle.

The Chocolate Moose line is shelf-stable for up to 18 months. The glass bottle, supplied by Zuckerman-Honickman, Inc., helps preserve the milk drink longer.

The Chocolate Moose redesign includes a new, shapely 16.9-oz bottle that hints at a traditional milk bottle shape. Stone adds, "The bottle has a quality feel. North American developed a product that is at the super-premium end of the chocolate milk segment. With the glass bottle and the full-body shrink sleeve, we achieved an impactful, clean design that should attract a wide audience."

Gravure printing

At the SleeveCo plant, printing of the shrink-sleeve label begins with a 16-in.-wide roll of unprinted film mounted to an automatic unwind unit. The film moves over a dancer roll to a Fife edge guide, which provides a proper oscillating roll wind. From there, the film travels to an infeed draw group inside the printing press. The press is equipped with a butt splicer, inline automation, inline die-cutting for pressure-sensitive labels, lamination, extended dryers and reverse-print stations for back-side printing.

At the first color station, film passes over a print cylinder that applies the first ink color onto an engraved cylinder. An ink dam forces ink into gravure cylinders and applies the image to the film. Next, a doctor blade removes any excess ink from the film. The press's dryer system conforms to the National Electric Code (NEC) and is classified as explosion-proof in accordance with NEC standards.

|

Above, a web-inspection device, separate of the gravure press, checks the finished shrink-sleeve seam for print registration with a black light. The slitter, right, slits the edge-trim and inspects for print defects. |

Printing challenges include the shrink-sleeve's graphics being composed completely of process colors, and the metallic gold ink laydown, says Martin Wilson, director of sales and marketing at SleeveCo. "Even the nutritional label is a process color, so a spectrodensitometer is used to maintain color consistency for the entire label," he adds. "Also, a great effort is made for the ink laydown of the metallic ink color bar. We are trying for the highest reflectivity possible with that color."

For registration, the press has an Electromat DGC 650 register control that monitors the Moose film by sequential codes. BST Promark high-resolution cameras inspect the film and check the film's print quality and density values. The press uses an Automation Direct programmable logic controller, model CPU-DL-250-1.

Completing label production are a slitter and a fully dedicated inspection machine. The Rotoflex VLI slits the edge-trim and also provides automatic print-defect detection. Then, a DCM Baby Cat inspection device checks the finished shrink-sleeve seam for print registration and integrity with a black light.

Award-winning moose

Like many other beverage and food producers, North American Beverage has seen the splash full-body shrink sleeves offer and has taken the plunge. The Chocolate Moose label just won the gold medal for label design in the 9th Annual Beverage Packaging Global Design Competition sponsored by Murray J. Lubliner Associates. With any more success, this hip moose might need more than one pair of sunglasses.

More Information is available:

Label design: Roar Marketing Group, 203/662-1221. Circle No. 226.

Label converting: SleeveCo, Inc., 800/624-0204. Circle No. 227.

Film: Klöckner Pentaplast, 540/832-3600. Circle No. 228.

Press: W.R. Chesnut Engineering, Inc., 973/227-6995. Circle No. 229.

Bottles: Zuckerman-Honickman, Inc., 610/962-0100. Circle No. 230.

Edge guide: Fife Corp., 800/639-3433. Circle No. 231.

Control, inspections: Electromat Electronics, Inc., 757/487-8849. Circle No. 232.

Inspection: BST Promark, 630/833-9900. Circle No. 233.

PLC: Automation Direct, 800/633-0405. Circle No. 234.

Slitter: Rotoflex International, Inc. 905/670-8700. Circle No. 235.

Inspection: DCM, 33 141 375270. Circle No. 236.

About the Author(s)

You May Also Like