October 4, 2019

Packaging robotics advocate and changeover wizard John Henry didn’t see everything he wanted to see at the recent Pack Expo Las Vegas 2019 show. But he witnessed these noteworthy developments you should know about.

I used to be able to walk the entire Pack Expo show in its earlier days. Then, as the event grew, I would walk a lot of it and worry about what I was missing. Now I just see as much as I can because it is no longer possible to see everything.

I did get to see a lot of really nifty stuff though. I saw some new technologies, new uses of old technologies and upgraded technologies. Here are four that stand out:

1. One of the more interesting technologies helping to advance robotics in packaging is machine vision or camera systems. These used to cost tens of thousands of dollars and didn’t do a lot. Now they cost as little as tens of dollars and can do virtually everything.

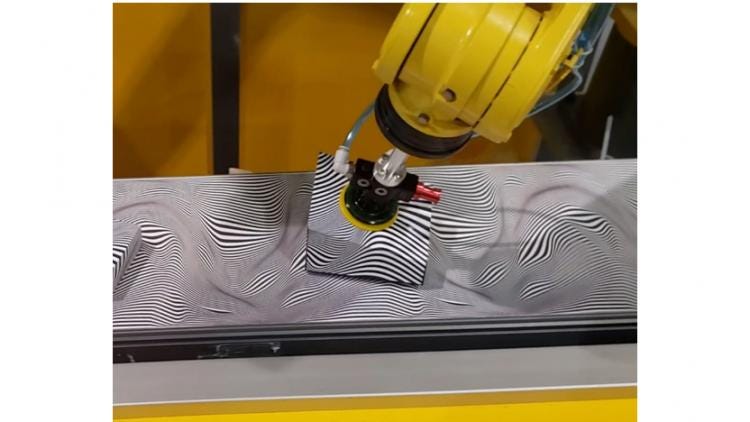

Perhaps the most impressive camera system I saw was coupled with a picking robot at Fanuc Robotics.

3D cameras have been able to sense part height and position for a few years now. This one sensed height, position, orientation. More impressively, it could detect an angled surface as shown in the photo (above/below). Most impressively, it did it with a dazzle pattern carton on a dazzle pattern belt—while in motion. I could just barely see the cartons, but the camera never missed.

I don’t expect to see many camouflage operations on a packaging line, but if the system could handle this, any other application will be easy as pie, even if the product is (literally) a piece of cake.

2. I’ve known that Epson builds great SCARA and other industrial robots. But its IntelliFlex Feeding System blew me away. The system fed keys out of a bin onto a vibrating tray. A camera identified which keys were right side up, the SCARA robot picked them, oriented them and placed them. When all keys were picked, the vibrator flipped over the remaining keys for picking. It did all this in less time than it took to read that sentence. It left my mind racing with possibilities.

This simple system could be a bottle orienter, filler, capper, labeler and …? An entire packaging line could be built around a series of these robots.

3. I have seen automated guidance vehicles (AGVs). I’ve seen cobots. I’ve even seen them combined by integrators. But I had not seen a single company solution until Omron.

Omron has combined both into a mobile robot that can go to the stockroom, pick some parts and materials and carry them back to the line. When finished, it goes to the nearest charger to juice up until needed again.

One question I have is what to call it? The base is a mobile robot or mobot. The arm is a collaborative robot or cobot. So is the system a comobot? Or perhaps a mocobot? We’ll be seeing more of them, we need a catchy name.

4. Blessings in a Backpack is a PMMI initiative to provide backpacks of food for children who might otherwise go hungry. A number of integrators set up work cells in the Robotics Zone to assemble the various components.

Universal Robots’ partner Allied Technology was bagging, casing and palletizing products for the backpacks. The whole cell was fascinating, but the bagger was ingenious. A UR cobot picked a premade bag, positioned it for loading then placed it in a sealer. A bagging machine without the bagger. This is how packaging machines should be built.

I didn’t see everything I wanted to, but I did see a lot and walked 15 miles doing it. I can’t wait to do it again next year in Chicago.

____________________________________________________________________________________________

MinnPack 2019 (Oct. 23-24; Minneapolis) is where serious packaging professionals find technologies, education and connections needed to thrive in today’s advanced manufacturing community. See solutions in labeling, food packaging, package design and beyond. Attend free expert-led sessions at multiple theaters around the expo.

About the Author(s)

You May Also Like