Cooperative Robots – A New Twist on the Factory Floor

Cooperative robots sound like collaborative robots but they offer different functionality in plant automation.

April 4, 2023

What the heck is a cooperative robot? Hint: it’s not a cobot. Cooperative robots are separated from human workers by a barrier.

Collaborative robots, commonly known as cobots, are robots that work side-by-side with human operators. Unlike industrial robots that are separated from human operators, cobots share the same working space as humans. As a relatively new definition, cooperative robots sound like collaborative robots but they represent a different nature of the operation.

According to IDTechEx, cooperative robots are industrial robots with a virtual fence between human operators and themselves. The cooperative robot stands in the middle of industrial robots and cobots, combining the benefits of industrial robots and collaborative robots with the aid of safety sensors, which are typically laser scanners.

Finding the Cooperative Robot Fit

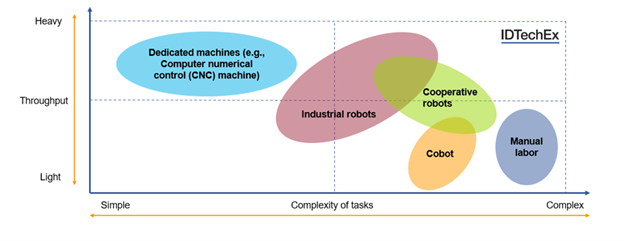

Here’s a chart showing the relationship between machines and humans by productivity and task complexity. Humans and cobots are more competent in handling complicated tasks, yet they usually have a much lower throughput compared with industrial robots. On the contrary, industrial robots and dedicated machines have high productivity but limited ability to handle complicated tasks as they are programmed specifically for a specific task.

What Are the Pros and Cons of Cooperative Robots

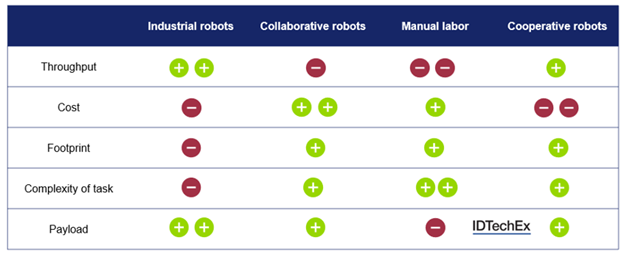

Cooperative robots combine the benefits of industrial robots and cobots. The table below compares cooperative robots, cobots, industrial robots, and manual labor. Strictly speaking, cooperative robots are a type of industrial robot. Yet unlike traditional industrial robots that rely on physical fences, cooperative robots utilize LiDAR-based virtual fences to split the workspace so that the footprint of cooperative robots can be significantly reduced compared with traditional industrial robots with physical fences. However, this also comes with a drawback: the high total cost. Compared with traditional physical fences, LiDAR-enabled virtual fences can be ten times more expensive.

The Outlook for Cooperative Robots

Cooperative robots have demonstrated potential opportunities to increase the productivity of robots while maintaining a high level of human-robot interaction. The fundamental barrier to adoption is the high cost. LiDAR is relatively expensive, and depending on the specifications, it can cost thousands of dollars. An alternative option is using light curtains to replace the physical fence.

Robot users replace one or multiple fences with light curtains made of photoelectric sensors to enable easier access for human operators compared with physical fences. Depending on the resolution, the cost of light curtains is typically between $300 and $500.

Cooperative robots have demonstrated a higher working efficiency and a higher level of human-robot interaction compared with traditional industrial robots and emerging collaborative robots. At this stage, because of the high costs of LiDAR, the adoption of cooperative robots remains relatively low.

About the Author(s)

You May Also Like