Robots come to grips with pizza

January 29, 2014

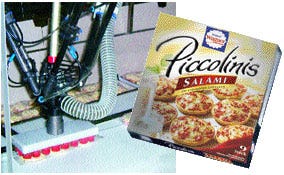

Wagner, of Nonnweiler-Braunshausen, Germany, had the enviable dilemma of the need to ratchet up production to meet an increased demand for its Piccolinis miniature frozen pizzas. The manufacturer was looking for a faster and more efficient production process, that offered a compact solution with a lower level of complexity, as well.

Wagner introduced Piccolinis to the market in 1996. These small, crunchy pizza snacks are targeted at families with small children and also single adults. So successful is the product that a single variety, Piccolinis with salami, can keep production running for up to four days at a time. At peak production periods, 900 pizza snacks are turned out every minute. This corresponds to 100 boxes/min, or 1,296,000 Piccolinis per day.

|

Robotics have helped boost production speeds in the pillow packing/cartoning of small pizza snacks. At the peak of production, nearly 1.3 million Piccolinis are packaged every day. |

With the intent of finding the technology to fit the product, rather than the product fitting the technology, Reinhard Ristau, technical director at Wagner, sought a better packaging solution that would offer considerably higher speeds than the previous cartoning machinery. He found his answers at SIG Pack Systems.

Space restriction presented a problem for Wagner, too, leaving few possible options for the cartoning of prepacked pizzas. This led Wagner to the decision to use robots. "This is the first time we have used robots," explains Ristau. "After seeing them being used for packaging, I can now imagine there are also many interesting possibilities for the use of robots in the manufacturing process." Wagner chose SIG Pack Systems for its move to robotics because it was able to offer a more compact solution with a lower level of complexity at a competitive price. Wagner's decision was also partly based on its use of existing SIG pillow-pack machines, which are still in use and have proved to be an extremely successful investment.

The new packaging system has vastly increased production. The Piccolinis are packed three-up on a SIG HBM pillow-packing machine. The packs are then spread across three lanes and are transferred to the cartoning machine. This addition comprises three SIG Delta robots, each capable of placing more than 100 triple Piccolini packs/min into the ready-made cartons. The packages are detected by a vision system with image processing that enables each robot to accurately locate each pillow pack and precisely place it into the preformed carton. Each robot arm matches the speed of the conveyor belt to ensure an accurately centered pickup of the products. The system was designed to give even distribution between packages and ensure an equal workload of all three robots. At the end of the system, the cartons are closed, sealed and cased.

The increase in production has allowed Wagner to cope with even further increases in sales. Between January and May 2003, turnover increased by 8.4 percent. Wagner attributes its continuing success to its clear concepts and innovation; high quality standards; and branding.

More information is available:

Robotic cartoners: SIG Pack Systems, 41 52 674 7419. www.sigpacksystems.com. Circle No. 245.

About the Author(s)

You May Also Like