Compostable snack packaging builds 'natural' image

January 30, 2014

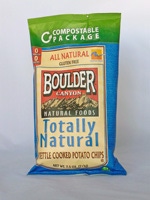

Healthy, active people often have high expectations for the foods they eat and the packaging in which it is sold. Snack maker Inventure Group, Phoenix, AZ, aims to meet both sets of expectations with its Boulder Canyon Natural Foods brand of potato chips and dips. That is why about a year ago Boulder Canyon adopted compostable packaging for its chips.

Thick-cut, kettle-cooked chips such as Boulder Canyon's have grown in popularity in recent years. Many of the people buying these products are concerned about both flavor and the nutritional value of the snack, as well as the environmental impact of the packaging.

Tanner Clark, product manager, says Boulder Canyon, which was launched in 1994 in Boulder, CO, has always been very eco-minded. The earth, he says, plays a central role in their customers' activities.

Learn more

Boulder Canyon's biodegradable packaging will be the subject of a presentation by Chris Mitchell, Innovia's sales and marketing manager for packaging and sustainable films, and Bill Reilly, development manager of Genpak, at the Sustainability in Packaging 2011 conference to be held Feb. 22-24 in Orlando, FL, for more information and to register, please visit www.sustainability-in-packaging.com

When Boulder Canyon set out to design compostable packaging, they wanted to "keep the integrity of the brand at the forefront," he says, adding that they sought to keep the same look and feel of the packaging they were already using while adding environmental benefits.

Genpak, a Toronto-based converter that was already supplying Boulder Canyon, worked with them to develop the new compostable bags. Bill Reilly, development manager for GenPak, says his company came up with a three-ply laminated structure that met stringent requirements. It includes an outside layer made with SFI-certified paper; a middle barrier layer of Innovia's Natureflex metallized cellophane made from wood pulp; and an inner layer made with BASF's Ecoflex biodegradable plastic, which has properties similar to LDPE.

The new packaging had to meet the American Society for Testing and Materials (ASTM) 6400 specification for compostable plastic, covering plastic products that are designed to be composted in professionally managed municipal and industrial composting facilities. The standard focuses on whether those materials will disintegrate and biodegrade swiftly and safely at a satisfactory rate.

In addition, Reilly says, numerous other factors were considered, such as the productivity in Boulder Canyon's packaging operations, shelf life and sealability.

The package is also certified by the Biodegradable Products Institute, which involved extensive testing to ensure it contains no heavy metals, supports plant life and breaks down within six months leaving no harmful materials.

Reilly says the only other biodegradable option was polylactic acid (PLA) materials. However, he said they were concerned with some of PLA's properties, including how well it machines, its sensitivity to heat and the growing public concern that agricultural land is being used for packaging and biofuel materials.

Beyond the materials chosen for the packaging, Reilly says that Genpak tries to make the entire manufacturing process more sustainable using water-based adhesives and by using the eight-color Opaltone printing process, which they say reduces solvent use by 40 percent.

There were also concerns about the noise associated with some PLA packaging. The biodegradable packaging that they chose gives the look, feel and sound as their earlier packaging, says Boulder Canyon's Clark.

The packaging features a green band across the top that says, "Compostable Package." Clark says awareness of the bag's environmental benefits is growing. "People who see it, really like it."

About the Author(s)

You May Also Like