Designers and engineers find value in smart packaging

Today’s smart packaging technologies already deliver myriad benefits, but this sector is quickly evolving in many areas. For example, in 2015, you were interested in hearing about how brands are connecting with consumers via their smartphones, how smart sensors can improve packaging machinery performance and how various smart technologies can help ensure product safety.

Packaging Digest continues its review of the top articles of the year based on page views with the 2015 top 10 reported developments in smart packaging.

Our list starts at the bottom and builds up to an exciting #1.

#10. The Club Connected Bottle from Rémy Martin (see photo above) tapped near-field communication (NFC) technology and a smartphone app to help consumers authenticate the product, tell if the bottle had been opened already or not, and download rewards and special offers. Augustin Depardon, the company’s executive director, explains the impetus behind the decision to incorporate an NFC tag on their cognac bottle: “As the world is becoming connected, our consumers are expecting their favorite brands to do more than deliver the finest spirits: they want to have a direct connection with these brands, and a direct engagement.”

Next: NFC on steroids?

#9. What’s better than an NFC tag? How about one that also integrates radio frequency identification (RFID) technology? Why choose one over the other when you can have both with the DualWing integrated tag? This new product provides the latest anti-counterfeiting and validation capabilities using common identification data that can be shared or updated by both NFC and RFID devices.

Next: Company protects wine shipped to Asia-Pacific

#8. Ferngrove Wine Group needed an anti-counterfeiting solution for its exports to China. So in the summer of 2015, it began a field test of using OpenSense NFC tags on bottles and was able to gain transparency and accountability at all stages of the supply chain.

Next: A more direct method

#7. CustomWave RFID Solutions can directly print an RFID antenna onto a label or packaging materials for greater flexibility in incorporating the technology into various packages. The thinner solution optimizes label roll sizes and, because it reduces the number of manufacturing steps, helps reduce total cost of implementation. The technology can be used for inventory management and theft control in retail, as well as for asset tracking and product authentication in automotive, healthcare or logistics.

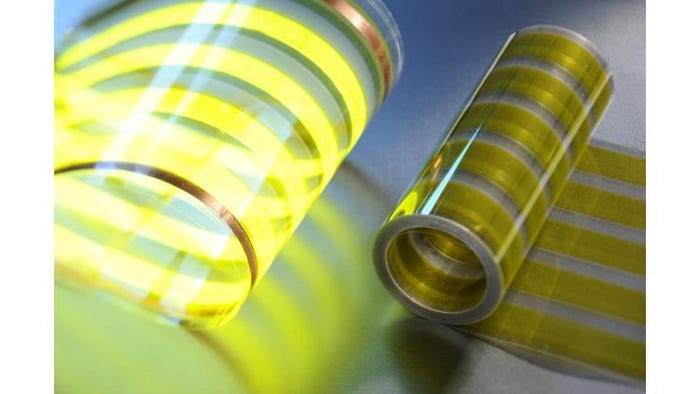

Next: Shining light on smart packaging

#6. Organic light-emitting diodes (OLED) can literally light up your packaging, cost effectively, to call attention to your brand on busy store shelves. A Finland-based company created technology that directly prints OLEDs onto a variety of packaging materials. According to the manufacturer, the technology has been “proven in a roll-to-roll production facility. The performance and stability, in terms of brightness and lifetime, is foreseen to improve.” Sounds like this has a bright future in packaging.

Next: Rising to the NFC challenge

#5. What better way to see and understand the potential packaging applications of NFC technology than by experiencing it for yourself? That’s what we thought. So Packaging Digest applied an NFC-enabled tag to the cover of our Summer 2015 issue and invited you to play. We provided an incentive, and also shared some compelling statistics about the technology. And knowing how packaging professionals appreciate proof of concept, we also included examples of several progressive brands that see real opportunity in engaging consumers in a digitally-driven market.

Next: Smart packaging floats to the top

#4. How can brands flip the scary issue of food safety into a positive message? Retailer chain Fresh & Easy did it by using smart packaging to reassure consumers that the store-brand seafood products were safe to consume. A Fresh Meter time-temperature-indicator label uses intelligent temperature-sensitive ink to indicate the product’s shelf-life status. TTI labels have been around for a long time, yes. But what’s new and different about this technology is that the preprinted labels are provided to the processing and packaging plant and are activated inline after tray sealing.

Next: How to leverage smart packaging

#3. Smart packaging guru John Van Akkeren succinctly enumerates 10 ways smart packaging can illuminate your brand. “In its purest form, smart packaging is a way to differentiate products and elevate brands,” Van Akkeren poses. The payoff: increased brand loyalty and powerful revenue gains. Personally, I can’t wait to see more smart packages strong in the “sensory experience” area (see point #7).

Next: Smart secrets to improving packaging line performance

#2. Being able to aggregate small data—using smart sensors on packaging machines—into Big Data gives packaging operations a host of benefits: reduced downtime and product waste, better predictive maintenance programs, plant safety assurance, improved product quality and increased throughput. Digital communication from these smart sensors gives packaging engineers insight and intelligence they never had before—and in real time, greatly improving their response times and efficiency. We also provide a couple case-study examples.

Next: Diageo sees endless possibilities

#1. In March 2015, global alcohol beverage leader Diageo stepped up and out with a prototype “smart bottle” for its Johnnie Walker Blue Label whisky designed to enhance the consumer experience and deter counterfeiters. The customer experience changes along the way, depending on the status of the bottle. For example, consumers tapping the bottle at home, after breaking the seal, will be able to access more or different digital information with their smartphone than what they saw when engaging with the unopened bottle at the store. The Diageo spokesperson says, “This is very much a prototype and not a commercial product, and so the team is still exploring with concepts and possibilities, but the main aim is to enhance the consumer experience. What we can say is that the possibilities are endless once the bottle is made ‘smart’—the information/data/content available are in theory limitless.”

Now that’s smart thinking.

__________________________________________________________________________

Learn about the latest developments in smart packaging at WestPack 2016, Feb. 9-11 in Anaheim, CA.

__________________________________________________________________________

About the Author(s)

You May Also Like