New techniques and technologies are adding value to various flexible packaging, incrementally and, in some cases, explosively.

The results of these production and printing advances in pouches, bags, films and labels become self evident each year through the industry's own competition—and this year is certainly no different.

For its 55th Annual Flexible Packaging Achievement awards program, the Flexible Packaging Assn will honor 15 packages with 20 awards in four categories: Packaging Excellence, Printing Achievement, Technical Innovation, and Environmental & Sustainability Achievement. Two packages have also earned the competition's Highest Achievement Award, deemed by the judges as having contributed most to the advancement of flexible packaging.

The trio of judges this year included one of PD's own, editorial director John Kalkowski, joined by Larry Ahleman, master faculty specialist, Western Michigan University and Mike Richmond, co-founder, Packaging & Technology Integrated Solutions (PTIS).

FPA presented the awards at a dinner held March 9, during its annual meeting at the Ritz Carlton Golf Resort in Naples, FL. All 78 competition entries, including the winners, were on display throughout the three-day meeting.

Flexible Packaging Assn, 410/694-0800.

www.flexpack.org

A fresh-cut above

1. A fresh-cut above

The Fresh N Tasty Produce Pouch, developed by Robbie Fantastic Flexibles for fresh-cut fruit and vegetables, offers multiple value-added benefits to consumers, processors and retailers, some not answered by existing competitive rigid containers. Because of these advantages, the package bags three awards: Highest Achievement, Gold for Packaging Excellence and Gold for Technical Innovation.

The bottom-gusseted stand-up pouch—a proprietary multi-layer lamination available as rollstock or pre-made packs—scores from technical, functional, economical and sustainable aspects.

The technical innovation is tiny, but only in looks. Laser micro perforations control the oxygen transmission rate of the package to slow the ripening rate of the produce inside. This extends shelf life and better preserves product quality. The size and number of micro holes are customized for the exact needs of each product.

What's new here, though, is that during material manufacturing, Robbie uses a patent-pending inspection process. A camera analyzes the micro perforations on each pouch and, if needed, the laser energy is automatically adjusted on the fly to maintain consistency and accuracy of the holes.

The bottom gusset also helps maintain product quality. It keeps the pouch upright and creates a reservoir to catch and contain excess liquids. Purging the liquid away from the product helps most fruits stay firm and fresh-looking for longer.

Robbie designed several packaging features to make fresh-cut produce more convenient for the consumer to help boost sales. This is supported by research from the Produce for Better Health Foundation, which says that 42 percent of consumers polled don't buy fresh produce because it's seen as inconvenient (too much work to wash, cut and prepare).

• A large viewing window lets shoppers see product freshness before buying.

• The flexo-printed graphics on all panels (compared to rigid containers that often only have small labels for communicating to consumers) offer high impact in stores. The study mentioned above also shows that 60 percent of consumers look to the supermarket for information such as recipes and storage. Adding these tips to printed packs could help increase fresh fruit or vegetable consumption.

• A built-in top hand-hole makes it easy for consumers to carry and handle at home.

• A press-to-close zipper lets consumers easily open and reclose the pouch.

• The bottom gusset keeps the package upright, minimizing unwanted spills, and a wide top opening makes it easy to scoop out the product or snack right from the pouch.

• The pouch has a slim profile, making it easy to store in crowded refrigerators, and can fold down to save even more space if needed.

It's the pack's smaller footprint—compared to rigid containers—that contributes to many of its economical and sustainable benefits.

For one, because more pouches fit in cases and on pallets, processors will reduce their costs for those components. Robbie commissioned a life-cycle assessment study, comparing one truckload of pouches at 780,000 units, with each pouch weighing 13.94 grams and measuring 11 x 7.5 x 3.5 in. against a typical two-piece rigid container/lid weighing 46.6 grams. LCA study results showed that, using this pouch instead of a typical two-piece rigid container/lid uses 57 percent less weight in corrugated boxes and 53 percent fewer pallets. Assuming it costs about $6.00/pallet for handling/warehousing, switching to the pouch would save $320/truck load.

Additional savings are seen on the front end, too. According to the LCA study, one truck load of incoming flexible pouches equals 4.2 times the number of trucks needed to ship cups and lids. In this equation, fewer trucks result in a savings of 77 percent CO2 and 77 percent on diesel fuel, plus the added labor savings because fewer drivers are needed.

Die-cut ‘wallet’ pays

2. Die-cut ‘wallet' pays

Called a "wallet," a flat, die-cut HDPE card protects medical device drills and pins so that they can be packaged in a sterile pouch instead of the typical thermoformed tray.

Earning three awards (Highest Achievement, Gold for Packaging Excellence, Silver for Environmental & Sustainability Achievement), the ConforMIS Drill and Pin Kit Wallet from Beacon Converters cuts the volume of packaging components by more than 93 percent compared to a thermoformed tray and uses less energy to produce and ship. It is also customizable for different products.

The card—made from virgin, medical-grade HDPE and compatible with any product approved for use with Tyvek—securely holds heavy and sharp orthopedic terminally sterilized devices of different sizes and shapes, and prevents them from potentially puncturing and breaking the sterile barrier, which would render the product unusable.

Products are hand-loaded into custom-cut slits and holes, organized in the exact configuration that the manufacturer requires. Each component is protected from the others to prevent abrasions, enabling these sharp devices to be packed in a simple, economical pouch that survives challenging distribution.

After product loading, the cards are folded and closed with flaps on each end that simply interlock. This creates a flat, contained package that slips into a typical chevron-sealed medical pouch. This design allows components such as orthopedic drill bits to be in two tiers when folded. When unfolded in the sterile field, the wallet allows easy access to each component for removal.

The compact size of the wallet was a consideration for two reasons. One, the streamlined size fits easily in the hand, making it easier and safer for nurses to unload the surgical supplies in the operating room. And, two, the product fits into a special shipping case (with a confined footprint) for next-day air delivery.

Compared to the usual thermoformed tray for these products, the wallet/pouch combination pack offers these economic and sustainability features:

• By reducing the pack's footprint, manufacturers realize significant savings in shipping costs, both incoming and outgoing. The wallets are made from flat, not formed, sheets of material. So they are packed densely for efficient incoming shipping. The 99 percent volume reduction significantly saves on the cost to ship from Beacon to the device manufacturer. Outgoing shipping costs are cut considerably, as well. The pouches take up 855 cubic in./1,000 units. The previous tray and insert pack (which, even nested, shipped quite a bit of air) needed 12,300 cubic in. This switch equates to a 93 percent space reduction.

• Tooling for the wallet card is a fraction of the cost of tooling for a thermoformed tray and inserts.

Although marketing isn't as critical for medical products as it is with consumer products, the wallet kits can be embossed with company/brand identities—or with a recycling logo because the material can be recycled in most industrial and municipal waste streams.

Anti-fade labels don’t sweat the sun

3. Anti-fade labels don't sweat the sun

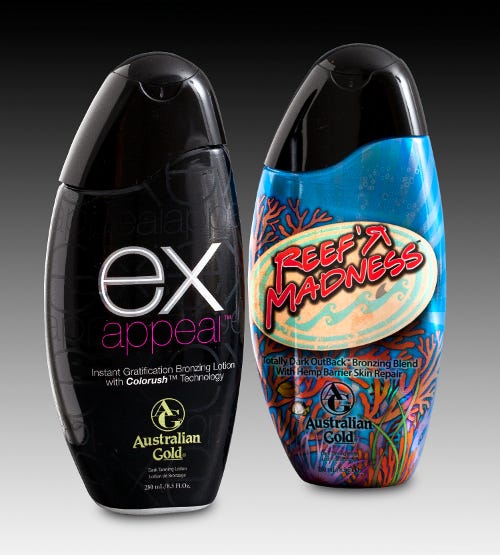

Winning Gold for Printing Achievement, the shrink-sleeve labels for Australian Gold's Ex Appeal and Reef R' Madness tanning lotions look and feel good.

We've seen converters mix glossy and matte printing for visual effect. Here, the combination has a functional effect, too. Label maker CL&D Graphics uses matte varnishes and UV-based inks to create contrasting textures on the surface. This, as well as the shape of the container, makes it easier to grip and squeeze the bottle, even with wet, slippery hands.

Flexographically printed using both UV- and water-based inks, the labels incorporate cold foils to create a shiny, metallic look that, along with the shapely container, catches the consumer's eye.

Touted as anti-fade, the labels are simply reverse printed to protect the inks from losing their vibrancy because of extended exposure to the sun.

Stepping out in style

4. Stepping out in style

Winning Gold awards for both Packaging Excellence and Environmental & Sustainability Achievement, the Fresh Step cat litter bag replaced a pail to reduce packaging materials by 77 percent.

The premade side-gusseted FlexZiBox bag with slider reclosure from Nordenia USA boosts the shelf impact of Fresh Step with its billboard and all-around graphics. Converted at the company's plant in Jackson, MO, the three-layer adhesive-laminated barrier bag is designed to ship and display efficiently and effectively.

Not only is the bag stable, it's easy for consumers to manage because of a robust handle (also a proprietary multilayer construction) that's incorporated into the substrate in the back of the bag. Although weighty at 42 lbs, the Fresh Step bag is easy for consumers to carry out from the store because of the patch handle. Consumers also have an easier, more controlled pour from the bag into a litter tray at home. The convenient handle—plus the easy-to-use recloseable top slider—lead to a more positive brand experience.

The stability of the bag during distribution was a key benefit over the previous pail. The top folds down to create a cube-efficient pack and is held down by a clear pressure-sensitive recloseable tape label. With this design, says Nordenia, Fresh Step brand owner Clorox was able to reduce the dunnage needed for outbound shipments while reducing damage. Only 2 lbs of dunnage is needed for the bags versus 144 lbs for the pail/lid package.

Additional supply chain savings tally up for incoming freight and warehouse inventory. According to Nordenia, one pallet of empty bags holds the same number of packages that used to require 13 pallets of pails and lids.

While the previous PP pail could have been reused by consumers if they chose to, it was often discarded and ended up in the landfill. Switching to the FlexZiBox results in 6x less material by weight being sent to landfills.

Sustainability improvements, measured by Nordenia using the Walmart Packaging Scorecard, add up like this: Compared to the pail, the bag shows an 83 percent improvement in greenhouse gas scores and an overall 63 percent improvement in scores across all metrics.

Films take abuse…really

5. Films take abuse...really

Holdouts for switching from metal foodservice cans to pouches have one more flexible option that addresses packaging performance issues head-on.

Earning a Gold for Packaging Excellence, Liquiflex Advance films for bulk liquids use proprietary layering technology to beef up the materials' strength so much that significant downgauging is possible without compromising structural integrity and package performance—even in abusive distribution and handling situations.

Converter Curwood Inc. constructs the coextruded films similar to how plywood is made, with thin layers overlapping to deliver compounded strength. This unique layer construction creates a film with the performance and strength of a 5.0 mil bulk film in 3.5 mils, which allows a 30 percent reduction of material compared to other liquid bulk films. When replacing the typical #10 metal foodservice can, the waste reduction is 96 percent.

According to Megan Raether, marketing communications specialist, in field drop tests, Liquiflex Advance films have outperformed competitive films (Curwood will share specific numbers on a confidential basis with customers).

The proprietary 13-layer films have redundant nylon and EVOH layers for high strength, abuse resistance and barrier. They can be flexo- or rotogravure-printed in up to 10 colors and be tailored for medium, high and ultra-high barrier. An opaque version provides protection from UV light. An optional feature is the EZ Peel "lift & peel" opening technology for safe opening without knives or scissors.

Designed for refrigerated, frozen or shelf-stable foods—from sauces and condiments to soups and stews—in weights up to 30 pounds, Liquiflex Advance films are able to go from the freezer to boiling water for easy food prep and serving.

According to the co., the films offer "excellent" organoleptic properties to protect and deliver the full flavor of foods. Although designed for institutional use, the materials are suitable for retail packs and for other heavy-liquid markets, such as detergents, motor oils and paints.

Additional sustainability advantages of the thinner films include:

• Because more film fits on a roll, the rolls offer better space utilization in transit and storage. Plus, there is less start-up waste during production because of fewer changeovers.

• Compared to #10 cans, Liquiflex Advance films use just 2 percent of space on incoming trucks to deliver the same number of packages, saving a significant amount of fuel.

• On outgoing trucks, filled pouches pack 40 percent tighter than filled cans, again resulting in significant fuel savings.

• Compared to the disposal of metal cans and other bulk films, Liquiflex Advance films create less waste by weight, possibly saving on landfill disposal fees.

Liquiflex Advance films are optimized to run on Curwood's Liquiflex AV Series Bulk Liquid vertical f/f/s equipment at speeds up to 40 bags/min., as well as any standard lap-seal bulk fillers. According to the co., the films "deliver outstanding machinability and thermal sealability for superior productivity." They are hot fillable up to 212-deg F.

6. Pet project peaks in printing

The high-gloss bag for Nestlé ONE Dog combines process and line printing to achieve just the right image for the brand: a nutritious formula designed to keep dogs at their peak. The 2.7 kg (almost 6 lbs) side-gusseted bag, supplied by Nordenia USA, is rotogravure-printed on five panels (front, back, two sides and bottom) and can be displayed laying down or standing up on store shelves.

Using process and spot printing, Nordenia was able to produce high-quality vignettes of adorable pets (including light halftones), as well as move seamlessly from light to dark printing. Nordenia uses MX-NA-1 inks from Siegwerk in seven colors (four process plus three spot inks) to achieve the premium look. The appealing graphics plus the natural sheen of the PET/PE adhesive-laminated film command shoppers' attention in the highly competitive "premium pet food" category.

Baby food pouch sprouts grown-up gains

7. Baby food pouch sprouts grown-up gains

The recloseable stand-up retort pouch for Sprout Organic Baby Food wins a Gold for Environmental & Sustainability Achievement, but also delivers several user advantages.

Produced by Ampac, the retort pouch is a packaging format change for a category replete with rigid containers, both glass jars and plastic cups. Comparatively, the flexible package cuts space, weight, energy and packaging component complexity.

Sprout touts the multi-layer structure (PET/foil/OPA/PP) as using only BPA-free plastics. While the foil barrier protects the flavor and nutrients, it also means the pouch cannot be heated in the microwave. Sprout Foods Inc. did this deliberately to minimize energy usage in the home and make the product conveniently more portable. The food can be served anywhere at room temperature or can be warmed by soaking a sealed pouch in hot (not boiling) water for a few minutes.

With a bottom gusset and wide top opening, the package is the serving dish, so consumers don't waste energy washing dishes or bowls after use.

Compared to glass jars and plastic cups, Sprout's pouch takes up less space in storage and shipping (incoming and outgoing), which saves energy, boosts efficiencies and lowers costs associated with transportation and warehousing. According to Ampac, these pouches can reduce the volume of waste in landfills by up to 94 percent compared to glass jars with lids.

Ampac studies show a significant advantage from a package-to-product ratio. Figuring a 3.5-oz pouch that weighs 6 grams and holds 99 grams of product, the ratio is 16.7:1, with the packaging as a percentage of the product coming in at 6 percent. The ratio for a 4-oz glass jar is 1.4:1, with it weighing 79 grams and holding 113 grams of food. That equates to the packaging counting as 70 percent of the product.

The number of primary packaging components weighs in, too. Ampac compared its printed retort pouch (one component) against the rigid cup (with four components: cup, lidding, overcap, paperboard sleeve) and the glass jar (consisting of jar, metal lid and paper label). Simplifying the number of components means there are fewer items to manage at Sprout Foods, which saves on labor costs, and less packaging for the consumer to dispose of.

Although the multi-material laminated pouches can't be recycled, they are being upcycled to keep them out of the landfill. Sprout has partnered with TerraCycle (www.terracycle.net) to collect used pouches and turn them into other consumer products, like tote bags.

We've already mentioned several convenience features: how the flat pouch is portable, easy to serve from, recloseable with a press-to-close zipper and non-breakable/safe. It's also easy to open, via Ampac's Linear Tear technology, which guarantees a straight tear across the pouch every time. Designed into the material substrate, Linear Tear also eliminates the need for laser or mechanical scoring on the line. Lastly, the pouch delivers great graphics through rotogravure printing.

THE WINNER'S CIRCLE

HIGHEST ACHIEVEMENT AWARD WINNERS

Fresh N Tasty Produce Pouch

Robbie Fantastic Flexibles, www.robbieflexibles.com

ConforMIS Drill & Pin Kit Wallet

Beacon Converters Inc., http://beaconconverters.com

GOLD AWARD WINNERS

Packaging Excellence

ConforMIS Drill & Pin Kit Wallet

Beacon Converters Inc., http://beaconconverters.com

Liquiflex Advance Films for Bulk Liquids

Curwood Inc., A Bemis Co., www.curwood.com

Fresh Step Cat Litter

Nordenia USA, www.nordenia.com

Printing Achievement

Australian Gold Tanning Set

CL&D Graphics Inc., www.cldgraphics.com

Nestlé ONE Dog

Nordenia USA, www.nordenia.com

Environmental & Sustainability Achievement

Fresh Step Cat Litter

Nordenia USA, www.nordenia.com

Spout Zippered Retort Pouch

Ampac, www.ampaconline.com

SILVER AWARD WINNERS

Technical Innovation

Cryovac Oven Ease Bags

Sealed Air Corp., Cryovac Food Packaging, www.cryovac.com

Zone Coated Rollstock

Oliver-Tolas Healthcare Packaging, www.oliver-tolas.com

Fresh N Tasty Produce Pouch

Robbie Fantastic Flexibles, www.robbieflexibles.com

Packaging Excellence

Hormel E-Z Zip Pouch

Ampac, www.ampaconline.com

Fresh N Tasty Produce Pouch

Robbie Fantastic Flexibles, www.robbieflexibles.com

Printing Achievement

John Soules Rotisserie Chicken

American Packaging Corp., www.ampkcorp.com

Masa Pizza

Peruplast S.A., www.peruplast.com.pe

Safeway Frozen Pasta Quad Seal Package

Berry Plastics Corp., www.berryplastics.com

Wyman's of Maine Juice

Printpack Inc., www.printpack.com

Environmental & Sustainability Achievement

Trail's End Classic Caramel Popcorn

Danafilms Inc., www.danafilms.com

Plastic Packaging Technologies LLC, http://plaspack.com

ConforMIS Drill & Pin Kit Wallet

Beacon Converters Inc., http://beaconconverters.com

See short descriptions of the Silver Award winners here.

.

About the Author(s)

You May Also Like