New ink may lower electronics costs for smart packaging

January 30, 2014

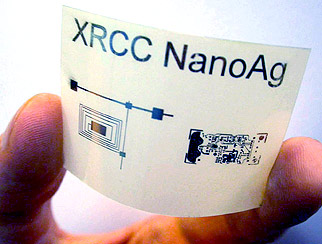

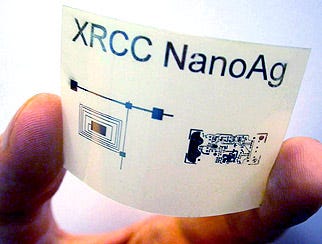

Xerox silver ink

A new conductive silver ink could provide low-cost manufacturing of printable electronics.

Developed by scientists at the Xerox Research Centre of Canada, the ink could help add computing power to a wide range of surfaces such as plastics or fabrics. Xerox cited multiple possible applications, including a "smart pill boxes that track how much medication a patient has taken" and low-cost RFID tags.

"For years, there's been a global race to find a low-cost way to manufacture plastic circuits," said Paul Smith, laboratory manager, Xerox Research Centre of Canada. The technology company states that the logistics and costs associated with silicon chip manufacturing is a hinderance to the development of the low-cost electronics and its low-temperature silver ink can offer reliable printing at low costs.

The new technology allows electronics manufacturers for smart packaging to print circuits in a fashion similar to how a print service provider prints a continuous feed document, thus eliminating the need for the extensive clean room facilities required in current chip manufacturing. In addition, scientists have improved their previously developed semiconductor ink, increasing its reliability by formulating the ink so that the molecules precisely align themselves in the best configuration to conduct electricity.

About the Author(s)

You May Also Like