Zippy new carton is revolutionary

A new carton tech

T.H.E.M.1_zip-pak.jpg

nology could be opening new marketing vistas for U.S. Sugar Corp. It is the first company in the world to market its product in a revolutionary new cartoning concept that integrates a poly-coated paperboard carton with an attached flexible film header containing a zipper. Zipbox is a joint venture between T.H.E.M. and the Zip-Pak division of Illinois Tool Works Inc. (ITW).

An innovative package format that combines the stability of a carton with the convenience of a resealable flexible package, Zipbox facilitate direct-filling of products without needing an inner liner.

T.H.E.M.

T.H.E.M.2.jpg

(Technical Help in Engineering and Marketing) is the primary inventor of Zipbox. ITW is the worldwide licensee and commercial interface to brand owners and converters.

Plantation brand sugar is first

The first product to be packaged in the new carton is Plantation brand sugar from U.S. Sugar Co., but the Zipbox is suitable for a variety of consumer applications, including cereals, snacks, cookies, frozen foods, pet foods and powdered laundry detergents. In fact, anything that can be packed

today in a carton with a liner, pouch or caniste

T.H.E.M.3.jpg

r is a candidate for the Zipbox.

Among the many features of the new Zipbox is a DoubleZip press-to-close zipper on top that allows for easy opening and closing. An airtight seal configuration on the package bottom eliminates the need for an additional liner to maintain product freshness. The zippered pouch folds down before filling for efficient sealing and shipping and is easily opened when the top flaps are lifted up by the consumer.

According to Neil Kozarsky, president and CEO of T.H.E.M., the liner-less design provides for a minimum of 10 to 40 percent additional content, and/or source reduction, when compared to traditional bag-in-box packaging and 40 to 60 percent better cube-out on pallets.

In fact, he says that the Zipbox's rectangular footprint offers better space efficiency than stand-up pouches and canisters all the way from manufacture to retailer shelves.

William

T.H.E.M.4.jpg

McDaniel, president and CEO of U.S Sugar Corp., says, "My customers are always looking for new packaging ideas, and there has not been a lot of innovation in the sugar category for a number of years. I like the idea that the Zipbox offers the best qualities of cartons and resealable pouches."

According to McDaniel, the Plantation line extension offers some key potential benefits for U.S. Sugar. "It will address a number of issues that retailers have with pouches throughout distribution. First of all, it's unique; it will stand out on the shelf in comparison to the traditional packages. The Zipbox merchandises well on shelf; it is very stable and secure.

"It is priced competitively with the traditional offerings, particularly when you consider total distribution and logistics costs. To emphasize the last point, cost is very, very important. Our analysis on a total system basis resulted in us moving forward with the Zipbox."

McDaniel continues, "We are in the early testing stages with key retailers. If our a

T.H.E.M.5.jpg

ctivities with the [Zipbox] raw sugar product is promising, we plan to expand to a complete line of sugars. In fact, we think retailers will almost require it."

To facilitate implementation of this new packaging concept, T.H.E.M. installed a short-run demonstration packaging line at its headquarters in Marlton, NJ. This enabled consumer-packaged goods companies (CPGs), like U.S. Sugar, to source filled Zipbox packages for consumer insights, product shelf-life and other testing.

"Bringing a brand new package format to market can be challenging for brand managers," Kozarsky says. "As we learned with our stick pack business, by enabling short-run production, we can provide guidance to companies who want to implement the Zipbox, allowing them to conduct research and bring it to market faster."

T.H.E.M. has a fully operational on-site R&D center located at its Marlton, NJ, headquarters, with pilot production to scale up capabilities.

Frank Ke

T.H.E.M.6.jpg

lly, business manager of Zipbox for ITW, says, "The Zipbox concept has generated considerable excitement from CPGs and consumers as an intuitive, easy-to-use carton unlike any package style on store shelves today. Demonstrating the ability to produce Zipbox on a broad scale is the next step in revolutionizing the way products are brought to market."

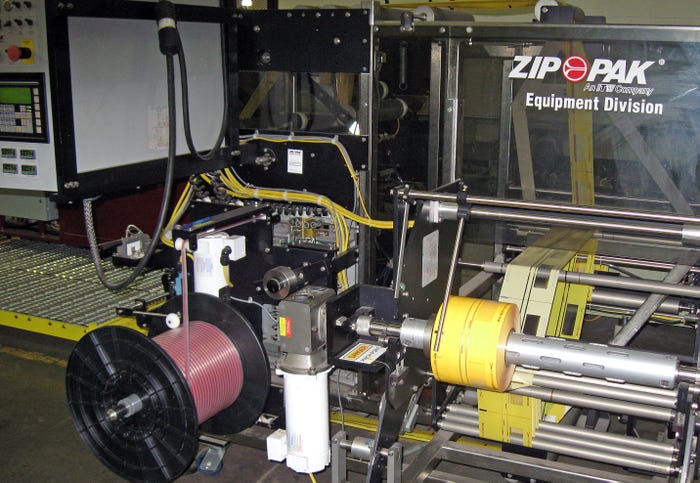

Producing the Zipbox

The Zipbox cartons are produced on a Model MP2 Assembly Machine from Zip-Pak Systems. This is the same machine that is used to apply zippers to flexible bags.

In this operation, folded cartons, which are supplied by Malnove Inc., are fed from a magazine at the inlet end of the machine onto a vacuum conveyor that transports them through the machine. The vacuum helps maintain the spacing between the cartons, which is critical, and top belts travel simultaneously with the cartons to help maintain exact control and spacing, which is ¾ in. in this case.

Zipper and film are on rolls on the front of the machine. The zippers are DoubleZip zipper profile from Zip-Pak and the high-barrier EVOH/PC/PE coextruded film is supplied by Curwood Inc.

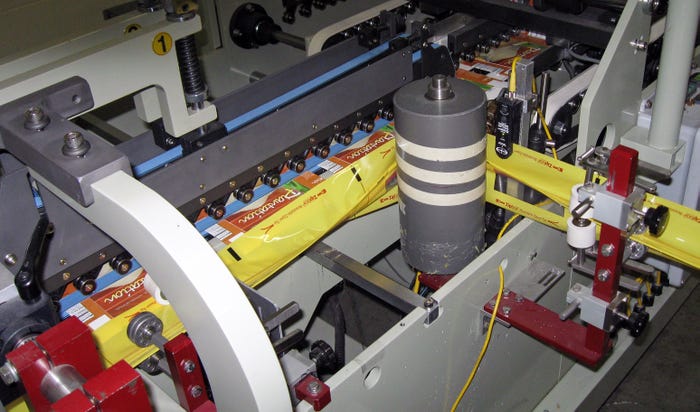

The flat film is pulled through directional and tensioning rollers as it enters the machine and is then folded to form a "C" shape with the trough of the "C" facing upward. The zipper is pulled directly into the machine and is inserted down into the trough in the film, which is heat sealed above it.

The film then passes over a right-angle plough so it is traveling beside the cartons. Ploughs open the sides of the film and rollers fold it over the edges of the carton, after which heated bars come together and heat seal the film to the cartons. Registration marks on the film regulate the film travel so it is always perfectly aligned with the cartons.

Ultrasonic units seal the film between the cartons, and a guillotine cutter descends to cut the film, producing Zipbox blanks. The Zipbox blanks discharge onto each other on a conveyor that gives a speed blip every 20 cartons to separate the stacks into groups.

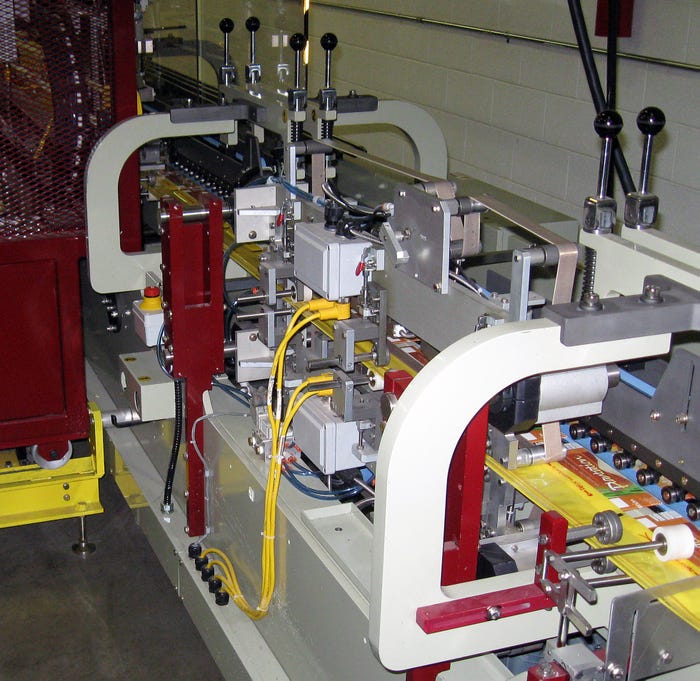

Carton erecting, filling and sealing

Carton erecting, filling and sealing is done on a system designed and built by Yeaman Machine Technologies. In this process, the Zipbox

T.H.E.M._0146.jpg

cartons are placed in a magazine with the zipper section facing upward. Suction cups on a rotating arm pick individual cartons out of the magazine and travel in a circular path to place the cartons into the lug chain of the erecting section.The cartons are filled through the bottom, so the arm rotates the cartons 180 deg during the transfer, so that they are placed in the carrier with the zipper tops on the bottom and the open carton bottoms facing upward.

According to Bill Yeaman, president of Yeaman Machine Technologies, handling cartons with the zipper attached is what separates this operation from standard cartoning operations. "We had a lot of trials and challenges before we finalized the system to properly seal the cartons," he says.

The box must have side gussets so that the film headers will take shape properly when the carton is erected. To erect properly, the plastic headers have to be partially folded in the same direction as they enter the lug chain, so the cartons travel past an upward sloping steel plate that pushes them all backward as they enter the chain.

Fingers on the two sides of the chain then come together to squeeze open the carton. Next, hot-melt glue is applied to the two ends of the plastic header, after which lugs rise and fold the plastic up onto the two end panels of the carton.

The next difficulty was that the folded plastic end flaps would pull loose before the glue set. To solve this, Yeaman installed metal brackets that slide down on each side of the carton to hold the end flaps in place. They rise to allow the cartons to be transferred to the filling section.

Yeaman is designing a different style carton erector that uses a horizontal ram to form the carton and Hartness Intl. Inc., which is a sister company to Zip-Pak, is also working on a proprietary carton erector for use with the Zipbox.

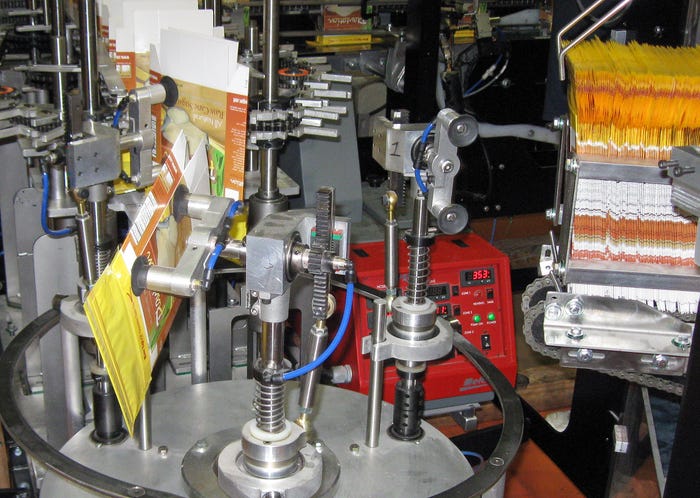

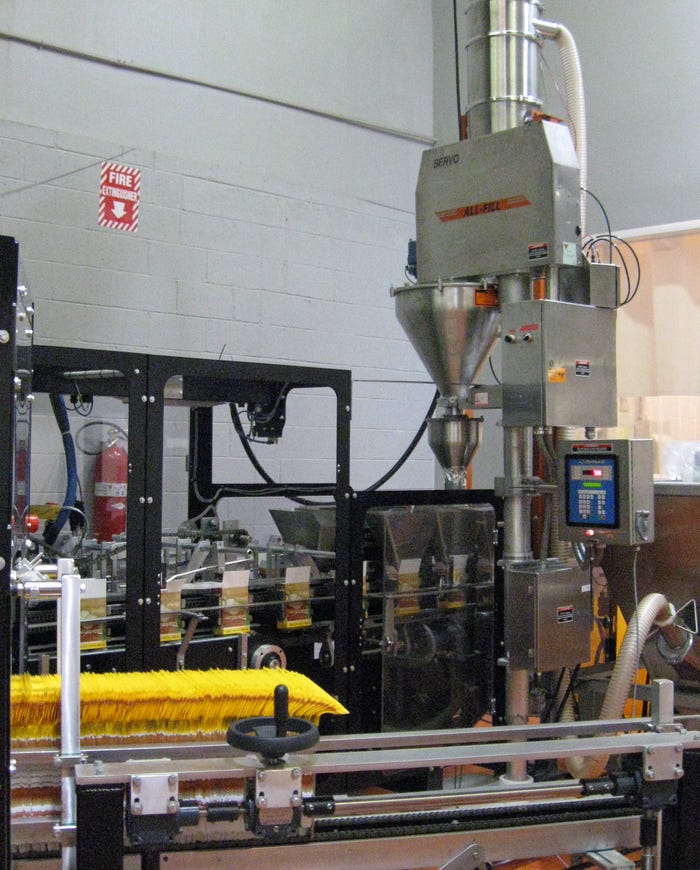

The formed cartons make a right-angle transfer into the carrier chain that transports them through the filler. The sugar is filled by an auger filler from All-Fill Inc. The filler uses a race-track arrangement of 10 funnels that travel above the cartons during the filling process. In this operation, the cartons are upside down and are filled through their bottoms.

After filling, the cartons are transported through the sealing zone of the cartoner. During Packaging Digest's visit, T.H.E.M. was gluing the sift-proof bottoms with hot-melt glue. The gluing system can be replaced with a heat-sealing system if the customer prefers that bottom.

The entire ZipBox production line is being moved to the Power Packaging contract packaging plant in Batavia, IL in January 2012. Production for U.S Sugar and future production of other products will be done there. Power Packaging, an Exel company, is the nation's largest contract manufacturer of consumer packaged goods.

According to Jim Ellis, senior director of sales and marketing, Power Packaging has partnered with T.H.E.M. on projects for years and was involved from the beginning with the Zipbox project. Ellis says, "Zipbox is an exciting first-to-world innovation that solves unmet consumer needs, meets CPG manufacturer and retailer green initiatives, and provides a unique branding opportunity for multi-serve products.

"Generally, new packages resonate with some groups and not with others. Zipbox is highly intuitive and tested equally well across all demographics in focus groups. CPGs and retailers are no different-everyone is interested in Zipbox."

All-Fill Inc., 610-524-7350. www.all-fill.com

Curwood Inc., 920-527-7300. www.curwood.com

Hartness Intl. Inc., 800-845-8791. www.hartness.com

Zip-Pak, Div. of Illinois Tool Works Inc., 773-715-3121. www.zippak.com

Malnove Inc., 402-330-1100. www.malnove.com

Power Packaging, 630-377-3838. www.exel.com/exel/pp_home.jsp

T.H.E.M., 800-322-8436. www.them.net; www.zipbox.net

Yeaman Machine Technologies, 847-758-0500. www.yeamanmachine.net

Zip-Pak Systems, 770-921-1777. www.zippak.com

About the Author(s)

You May Also Like