Spirits soar with new liquor filling/labeling line

January 29, 2014

Just as wine depends upon the perfect proportion of acidity and sweetness, fruit and oak, and alcohol and flavor to create a well-balanced taste, U.S. Distilled Products Co. (USDP) is placing more emphasis on a balance between short and long product runs, and own-brand versus copacked products to sustain its thriving business.

Establishing a bottling facility in 1981 for its own alcohol product lines, the Princeton, MN-based company later uncorked its capabilities for other brands. Today, with a recent brand acquisition, USDP has come full circle.

"We're trying to focus on a balance between our own brands and our relationships with other companies, so that we can keep our plant's capacity at a very high level," says Todd Geisness, general manager and executive vp of USDP.

Traditionally USDP's strongpoint had been in producing small runs of 100 to 200 cases of bottled liquor. Thus, it equipped its six filling lines with versatile machinery that allowed for quick changeovers. But, as its brands grew in popularity, so did its run lengths. This evolution, coupled with the competitive nature of the bottling market, drove USDP to install a completely new line, outfitted to accommodate larger-volume runs quickly and efficiently.

Scrapping its existing sixth packaging line, USDP put in place a new high-speed bottling system. As most of the new line was designed in-house by employees familiar with the company's needs, each piece of equipment was hand-picked from among a number of suppliers, including MRM/Elgin, A-B-C Packaging Machine, Accraply, Hartness, Videojet Technologies and others.

'If you build it, they will come'

Housed in a 245,000-sq-ft facility, USDP currently handles an intoxicating number of 2,800 stockkeeping units. These include cordials, white and gold spirits, wines, cr?mes and schnapps, and nonalcoholic products such as mixers and ready-to-drink beverages. McAdams Canadian Whiskey, Karkov Vodka, Rondiaz Rum, Luccio Chianti, Mothers Schnapps, and Jean Dur?e Cognac are just some of the brands marketed by USDP. Add to that the long list of drinks it copacks, and you have a fully stocked bar.

Contrary to what the company's name implies, USDP does not distill alcohol, but rather it purchases alcohol and other components from sources around the world and uses these ingredients to complete formulas, or recipes, supplied by its customers. After being blended, the liquor products are filled on one of the company's six bottling lines into bottles that can range in size from 0.200 mL to 1.75 L. USDP uses both glass and polyethylene terephthalate bottles, supplied, respectively, by Anchor through its broker, Saxco, and by Schmalbach-Lubeca.

Says Geisness, "Before the startup of the new line, the equipment that we had in place was very versatile; it allowed us to do many different bottle sizes and shapes, and to run at various speeds, which created a lot of flexibility for us. But, it did not allow us to run at very high speeds." By the summer of '99, USDP needed a bottling line that could produce its more popular brands, requiring longer production runs, with greater cost-efficiency.

The secondary motivation behind the new line was "kind of a Field-of-Dreams issue: 'If you build it, they will come,'" says Geisness. "We built it on speculation that it would make us even more versatile and attract other customers to our facility."

Clean installation

A tribute to the competence of USDP's employees, most of the planning and execution of the company's new line was carried out in-house, under the direction of maintenance manager Bill Rowland. Outside resources were used to provide CAD drawings and a line layout, and an engineering firm provided some helpful insight, "but eighty percent of the line design and how it was implemented was done in-house with Bill and his people," Geisness tells PD.

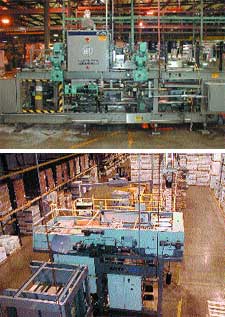

|

A decaser/single filer unpacks the bottles from reshippers, above, and positions them in single file on bottle conveyors. A p-s rotary labeler, right, applies neck, back and face labels at 300 bottles/min. |

USDP opted for Allen-Bradley SLC 5/03 controllers throughout the line, which were programmed by its master technician. Rowland says the company has always used Allen-Bradley controllers on its lines, due to their easy expandability, speed, and Ethernet capabilities, which allow the company to communicate with other machines.

The line was installed over a one-year time frame, with startup in January, '01. Outside of "a few glitches here and there," Rowland says, everything was delivered on time and in good shape, and the service backup from equipment suppliers was excellent.

Today, USDP typically runs three lines per 10-hr day, four days per week, maximizing the efficiencies of both its low- and high-speed equipment to meet various filling needs. To take advantage of the new line's speed, USDP minimizes changeover on the filler by limiting to three the number of bottle sizes run: .750 mL, 1 L and 1.75 L. "We could do all of the sizes if we wanted to," explains Rowland, "but we feel that it's not efficient to fill the smaller bottles, because the volume is just not there."

Due to the clean-running operation of the line's new MRM/Elgin-supplied filler, products of all viscosities are run, from water-thin spirits to thick and sugary cordials. But the largest volumes, notes Rowland, are in the spirits.

Gentle bottle handling

Starting off USDP's new line is a Model 156 decaser/single filer from A-B-C Packaging Machine Corp. Functioning as a flap-opener and positioner, as well as an unpacker and bottle single filer, the system is designed for operations running multiple bottle sizes. Providing minimum bottle-to-bottle contact, the machine is said by the company to reduce downed plastic bottles and help eliminate scratching of glass bottles.

Glass and PET bottles are supplied to USDP packed inverted in corrugated reshippers, which are carried to the Model 156 via an Ermanco roller-skate-style conveyor supplied by Conveyor Concepts. As each case is moved through the decaser, major and minor bottom case flaps are opened, and the bottles drop out onto a bottle conveyor positioned just slightly lower than the case conveyor. Once empty, cases proceed up an incline leading to an overhead conveyor that carries them to the end of the line. The decaser/single filer then very gently side-sweeps the bottles into a single-file lane, separating them with its unscrambling chains.

Rowland says that previous experience with A-B-C's equipment was a factor in the choice of the Model 156, as "they build a really good, heavy-duty, reliable machine," but the ease of changeover and speed of the machine were also critical issues.

After single-filing onto a bottle conveyor from Laughlin, bottles move through a U.S. Bottlers Sanitair air cleaner from Change Parts, Inc. Using a dual-stage cleaning process involving a combination of compressed air and vacuum, the Sanitair removes any contaminant particles from the bottles before they reach the filler.

Bigger is better for long runs

The heart of the new line is a 51-nozzle MRM/Elgin Husky 5 RFL rotary fill-to-level liquid filler that allows for gravity, pressure, or combination gravity/pressure filling. This versatility was vital to USDP's equipment selection, given the company's large range of product viscosities, and container sizes and materials. "To change over from one mode to another is fairly simple and can be done in about ten minutes," says Rowland. "It depends on both the product being filled and the bottle being used." Foamy products, such as sugar-based cordials, fill easier using the gravity method, while highly viscous liquids, like cr?mes, are filled more efficiently using pressure filling.

|

A vertical drop packer, top, joins filled and labeled bottles with reshippers at speeds up to 30 cases/min. The palletizer, above, offers a bi-parting plate apron that helps maximize operating speeds while minimizing drop distance, resulting in tight, square loads. An air-cushioned case turner gently handles products. |

Also attracting USDP to the equipment was the machine's exclusive bottom manifold feed design with shut-off disc. Says Rowland, "When we are pressure-filling our PET bottles, the manifold design relieves the pressure so that we don't have a lot of spills and drips coming off of the bottle when it exits the machine."

Also facilitating the machine's clean-running operation and uptime, an adjustable drive mechanism is positioned on top of the machine. Notes MRM/Elgin, "The inherent difficulty of filling liquids like cordials is the sugar content. When drive parts are below the fill level, the sugar can get into the mechanism where it's hard on cams, bearings and other machine parts."

Rowland adds that he was also impressed by the filler's ease of maintenance, made possible by a centralized lubrication system, and the quick changeover enabled by tool-less changeparts. Changing over from one product to another, while retaining the same bottle size, is a 20-minute process, he notes, while a full changeover can be accomplished in an hour and fifteen minutes. "If you look at the amount of nozzles we have, that's pretty quick," he says.

On average, the filler runs at a 230- to 250-bottle/min rate, for a total of 15,000 to 20,000 cases/day. This provides USDP with the ability to nearly double its previous output. Before installation of the new line, the sum total produced by all of its short-run lines amounted to just 10,000 to 12,000 cases/day.

Once bottles leave the filler, they are carried through a rotary capper from Pneumatic Scale (formerly Consolidated Capper), also purchased through Change Parts. The model TG-16-31 applies caps from Kerr Group in 28- and 33-mm sizes that offer a tamper-evident breakaway ring; 33-mm caps also include a built-in pour spout. The machine then tightens caps to a specific poundage designation.

P-s enhances look, speed

Matching the filler in speed and versatility, as well as in cleanliness, is the next piece of equipment on the line: an Accraply Model 9000R rotary labeling system. A break from its custom of using cold-glue applicators, the pressure-sensitive labeler was chosen by USDP for a number of reasons, says Rowland, including less machine cleanup, faster speeds and enhanced graphics capabilities.

Agrees USDP's Geisness, "If you look at one of our pressure-sensitive labels compared to a cold-glue label, you get a much purer product with pressure-sensitive," he says. "I think it's because of the versatility of printing options, and what marketers can do with the labels as a result of that."

The Model 9000R, in particular, was chosen, says Rowland, because of its ability to meet several criteria. First, the applicator had to be flexible enough to handle USDP's range of bottle sizes, with minimal changeover time. The Accraply labeler, he says, allows operators to change from one paper or film label to another in roughly 10 to 20 minutes, while programming for a new label can take anywhere from five to six hours, depending upon how many turns the bottle has to make.

|

The line?s stretch wrapper uses an overhead rotary design to spin a film web around the load, which remains stationary. |

The second criterion for the labeler was its ability to consistently apply spot labels in the correct orientation. As opposed to some other rotary machines that use a cam to turn the bottle plates, the Model 9000R is equipped with servo-driven plates that "can be programmed according to how many turns you want, how far you want the plates to turn, and in which direction you require them to turn," says Rowland. Once a container-movement profile is configured, it can be stored and downloaded to the servo from a touchscreen operator control panel. Using the Model 9000R, USDP is achieving a placement accuracy of ?1/16 in., estimates Rowland, at speeds up to 300 bpm.

Three applicators–applying neck, back and face labels, consecutively–make up the complete system, with room available for a fourth applicator, if needed. Labels are supplied by USDP or its customers, depending on the product, and range in size up to a maximum of 36/8 x 45/8 in.

After labeling, the back of the bottles receive a code by way of a Videojet EXCEL 170i ink-jet coder from Videojet Technologies (formerly Marconi Data Systems).

End-of-line flexibility

From Hartness International, two Model 825 vertical drop packers are the next stop on the line for filled, labeled bottles. Also chosen for their flexibility, speed and ease of changeover, the case packers handle shippers from 13 x 10 x 14 (tall) in. to 15 x 12 x 17 (tall) in., and can be expanded to accommodate additional case sizes, notes Rowland.

Diverted into two lanes after being coded, bottles are fed simultaneously to the packers, which load them into cases (delivered from the front of the line via conveyor) at speeds up to 30/min. Two packers provide double productivity while offering redundancy, "so that if something happens to one machine, the line does not have to be shut down," explains Rowland. Tool-less changeover is accomplished in 10 to 30 min, he says, depending upon bottle size.

Next, an A-B-C Model 336 automatic top case sealer folds the case flaps and seals the shippers at speeds up to 45/min. A Marsh CP/ML8 ink-jet case coder from Videojet, acquired through Jesco Industrial Supplies and incorporated into the sealer, then applies a government-required panel of information onto the sealed cases, which then convey to a palletizer.

Also new on the line, the Alvey 881 Series front-discharge palletizer meets USDP's varied case-size requirements. Typically, pallets are formed 12 cases/layer, five layers high, with pallet patterns being customer-specific. According to Alvey's machine specifications, the palletizer offers a bi-parting plate apron that helps maximize operation speed while minimizing drop distance, resulting in tight, square loads. An air-cushioned case turner provides gentle product handling.

After palletizing, loads are unitized using a new ITW Mima King Cobra automatic rotary-arm stretch wrapper. The machine uses an overhead rotary design to spin a film web around the load, which remains stationary during the wrap cycle. Eliminating the problem of film tails coming loose in transit, a patented heat seal welds the last rope of film to itself at the end of a cycle.

'Cheers' to the new line

According to USDP's Geisness, after just more than a year and a half in operation, the new line is virtually bug-free and is delivering "greatly increased productivity."

"You don't just flip a switch and have a new line work perfectly from the start," he says. "Certainly Bill and his team deserve a pat on the back for starting up the line so successfully. And, when Bill had a problem with the equipment, he contacted the suppliers, and they came in and worked with our people to resolve the issue. As a result, we just continue to get better and better and better. We're now really getting to the point where we have the system fine-tuned and feel very comfortable with all the equipment on the line.

"We have a very skilled group of people here," he continues. "We're very versatile, and we take pride in that ability. Installing the new line to increase our production capability enhanced our flexibility, and this has allowed us to become more efficient. And, obviously, the more efficient you are, the more competitive you can be when bidding on a contract. There is no doubt that our ability to be competitive has resulted in a lot more inquiries from potential customers."

More information is available:

Contract packers: U.S. Distilled Products Co., 651/649-5848. Circle No. 288.

Filler: MRM/Elgin Corp., 715/235-5583. Circle No. 289.

Decaser/single-filer, case sealer: A-B-C Packaging Machine Corp.,727/937-5144. Circle No. 290.

Labeler: Accraply, Inc., 800/328-3997. Circle No. 291.

Case packer: Hartness Intl., Inc., 864/297-1200. Circle No. 292.

Glass bottles: Anchor Glass Container Corp., 813/884-0000. Circle No. 293.

Glass bottles: Saxco Intl., Inc./Saxco Plastics, Ltd., 215/443-8100. Circle No. 294.

PET bottles: Schmalbach-Lubeca Plastic Container U.S.A., Inc.,734/428-9741. Circle No. 295.

Controllers: Allen-Bradley, 414/382-2000. Circle No. 296.

Case conveyors: Ermanco, 616/155-5415. Circle No. 297.

Case conveyors: Conveyor Concepts, Inc., 612/277-1250. Circle No. 298.

Bottle conveyors: Laughlin Corp., 817/ 232-9404. Circle No. 299.

Air cleaner: U.S. Bottlers Machinery Co., 704/588-4750. Circle No. 300.

Air cleaner, capper: Change Parts, Inc., 231/845-5107. Circle No. 307.

Capper: Pneumatic Scale Corp., A Barry Wehmiller Co., 330/923-0491. Circle No. 308.

Caps: Kerr Group, Inc., 800/367-1876. Circle No. 309.

Coders: Videojet Technologies, Inc., 800/654-4663. Circle No. 310.

Coder: Jesco Industrial Supplies, Inc., 800/862-0176. Circle No. 311.

Palletizer: Alvey Systems, 800/325-1596. Circle No. 312.

Stretch wrapper: ITW Mima, An Illinois Tool Works Co., 800/662-6462. Circle No. 313.

About the Author(s)

You May Also Like