Packaging Possibilities: Strategic Sourcing Smooths Supply Chain Shocks

Global foodservice manufacturer Golden State Foods shares helpful advice on how best to source packaging today.

When volatility is the norm, companies need robust risk mitigation strategies in that area. Today, the focus is on supply chains, as tight availability and sourcing challenges continue to create long lead times on some packaging materials, supplies, and equipment.

Luckily, Packaging Digest was able to talk with Trisha McRoberts, Group Vice President, Strategic Sourcing, Golden State Foods, a leading food manufacturer serving foodservice customers around the world. McRoberts talks tactics, as well as strategy, to help get through these chaotic times. She has great advice on …

• How possible is more local sourcing these days, after decades of a global economy and a shrinkage of USA manufacturing?

• Should companies continue to partner with strategic packaging suppliers, or should they have a cadre of acceptable packaging suppliers on the books these days?

• How is the cost of freight affecting the total landed costs of packaging today?

• What’s important to know about negotiating with packaging suppliers now?

PACKAGING POSSIBILITIES - Season 2: Episode 10

If you have a topic you’d like to propose for a future PACKAGING POSSIBILITIES episode, please email Lisa Pierce at [email protected].

TRANSCRIPTION IS AUTO GENERATED

Lisa McTigue Pierce

Hello, this is Lisa Pierce, executive editor of Packaging Digest, with another episode of Packaging Possibilities, a podcast that reveals what’s new and what’s next for packaging executives and engineers, designers and developers.

And this episode, I’ll be talking with Trisha McRoberts, Group Vice President of Strategic Sourcing with Golden State Foods. Golden State Foods is one of the largest diversified suppliers to the foodservice industry, servicing more than 125,000 restaurants from its 50-plus locations on five continents.

The company processes, packages, and distributes a variety of products, including liquids like sauces and syrups, proteins like hamburger patties, produce like lettuce and tomatoes, and dairy like yogurt, ice cream and coffee creamer.

Today, Trisha is going to give us some advice on sourcing and buying packaging in what is a bit of a challenging time. We’re going to talk about how the usual methods are changing and how you might be able to leverage some of those changes.

Trisha, hello and welcome! Thanks for talking with us today.

Trisha McRoberts (guest)

Hi, Lisa. It’s so great to be here with you today.

Lisa McTigue Pierce

Wonderful. So one solution ... There’s a bit of a supply chain challenge these days. We’ve heard about and are experiencing ourselves. One solution people have suggested to maybe alleviate some of the sourcing challenges that we’ve been seeing, whether it’s, you know, pandemic related or not, is to find more local sourcing. How possible is that these days, after, you know, decades of a global economy and also a bit of a shrinkage of US manufacturing?

Trisha McRoberts (guest)

Great question, Lisa. As that multinational enterprise, Golden State Foods operates food manufacturing facilities on five continents. So localization can mean a variety of different things depending on where we are throughout the globe. In this post-COVID environment where localization is trending, it can be complicated from a capability, capacity, and total landed cost perspective. Local sourcing provides the opportunity to reduce carbon footprint and demonstrate investment in the communities that Golden State Foods impacts.

However, we need to balance this with a mindset that’s focused on total reduction on the carbon footprint for our end-to-end supply chains. We are evolving toward a six-step sourcing process that includes analyzing all of these facets, which is looking at the different internal and external insights which continue to evolve, reviewing innovation, execution and continuous improvement, and not forgetting that post analytical results because sometimes we have the best intentions in mind and they don’t turn out exactly as we had imagined.

So today, we do have some robust local sourcing examples and one of this is with our GSF fresh produce operation in Australia, New Zealand, and China. We are in the process of looking at other packaging categories that could heighten our localization of sourcing throughout the globe.

Lisa McTigue Pierce

Is that pretty complicated to do, considering that you try to have some family look and some standardization across packaging?

Trisha McRoberts (guest)

I think that you know the graphics capability is something that can be monitored in different locales throughout the world, so I don’t think that is a real constraint. The larger constraint really is more on the infrastructure, the capability of manufacturing, and that total landed cost to ensure that the solutions are sustainable.

Lisa McTigue Pierce

OK, what does that mean? Landed cost?

Trisha McRoberts (guest)

So if we think about freight going up and representing about 11% of the total cost of goods in this increased freight environment and the complication with ocean freight and the complication with over-the-road freight as the number of drivers has reduced, it is playing a larger role in the cost of packaging and so certain packaging — for example, corrugated — you really don’t want to buy outside of a 250-mile radius but other more complicated packages lend themselves to global solutions that can, in some cases, be leveraged, but in other cases not as well, to enable a landed cost that is justified.

Lisa McTigue Pierce

OK. Makes total sense. I know that … at one point, our garbage company started adding a fuel surcharge to our bill and this was, I think, back during the Great Recession. And, you know, here we are, what 10 years from then, and that fuel surcharge is still on the bill.

So totally understand about the cost of freight in there. Interesting though that that plays a role in the total cost of the packaging. I guess I hadn’t thought of that until you mentioned it.

So one of the ways that companies in the past have been able to maybe control not only availability but pricing and, you know, further innovation and everything is to partner with strategic packaging suppliers. And some companies even have like a sole supplier for a particular package or a component, whether it’s something that they’ve partnered, co-developed with them or not.

Would you advise companies to continue doing so and gaining all those benefits of that kind of a relationship, which also sometimes would give them delivery priority and, you know, those pricing advantages or would you recommend that they explore Plan B these days and maybe have a cadre of acceptable packaging suppliers on the books?

Trisha McRoberts (guest)

Well, given the interdependent nature of our supply chains, interruptions at a facility can greatly impact connected companies across the country. So shutting down a line for packaging is something that nobody wants to do. Food manufacturers want to be enabling an environment where packaging is not the constraint. So if establishing a cadre of acceptable packaging suppliers in fact minimizes the risk of interruption, contingency planning through establishing relationships with multiple suppliers is something that companies should consider.

If establishing a cadre of acceptable packaging suppliers … minimizes the risk of interruption, contingency planning through establishing relationships with multiple suppliers is something that companies should consider.

In this environment, I would recommend that at minimum, a sole source supplier has a multi-line and multi-site solution that enables an active risk-mitigation plan. Volatility is the norm and site interruptions due to weather, labor, or technical interruptions are going to happen. So supply chain flexibility and adaptability are critical to successful execution. These plans cannot just be on paper and tested reactively when it a situation occurs. But they really need to be proactive. Part of the plan, monitored and actively tested, tested in real supply-and-demand scenario changes.

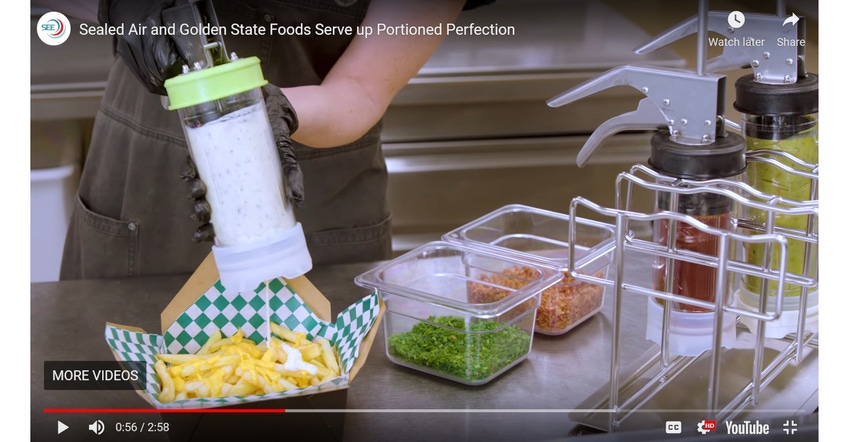

One thing that is very important to Golden State Foods is long-term relationships and deeply embedding our partners relationships. In fact, this February [2022], Golden State Foods was recognized by a prestigious innovation award for development and implementation of the transformation of a sauce-portion-dispensing solution. This was piloted in partnership with McDonald’s, one of our customers, and our packaging supplier Sealed Air. It has a ton of great benefits and a lot of times you cannot get these benefits without significant long-term relationship investment. And in this particular case, this product produces higher yields, cost savings, equipment simplification, freight efficiencies, decreasing storage footprints, and it optimizes the back of the house operation for our QSRs [quick-serve restaurants]. It also reduces waste to landfill and it renders reused squeeze bottles and corrugated packages obsolete within the QSRs.

So this is a really exciting evolution, an example of a partnership that shows the importance of maintaining strategic packaging relationships, but also ensuring that you can execute and within your manufacturing footprint and have a backup plan as well.

Lisa McTigue Pierce

What a great example. Thanks for sharing that with us. That actually brings up a question, another question that I had. So similar to some other changes that we’ve been seeing with local sourcing. There’s been talk about the difference between just-in-time deliveries and holding inventory. And we all know inventory is expensive to maintain, but with some of these challenges that we’ve been seeing in availability and delivery, where should manufacturers be right now as far as storing an inventory, holding an inventory versus the just-in-time delivery that we’ve been, kind of almost has been the norm for quite a while now.

Trisha McRoberts (guest)

Well, in an inflationary environment, cash is definitely King and no manufacturer wants to be holding inventory that is unnecessary. That being said, we do know that lead times throughout the globe are increasing and our complicated environment that the supply chain is undergoing. So I think, you know, it’s … what’s really important is to have great data and digital analytics to be matching your supply and demand plans so that you’re not over inventorying on materials that are not critical or not ones that require a floor stock to maintain manufacturing to be sustainable.

What’s really important is to have great data and digital analytics to be matching your supply and demand plans so that you’re not over inventorying on materials that are not critical.

But I do think it is a very important topic in our times and with the improved digitalization tools for S&OP and better connecting supply-and-demand signals, we can really manage this more effectively than we ever have in the past.

Lisa McTigue Pierce

S&OP, I’m sorry. What is that?

Trisha McRoberts (guest)

Sales and Operations Planning. So if, you know … it’s really kind of matching the demand of your customers to what you’re manufacturing to what your suppliers should be producing for you to enable a most efficient end-to-end supply chain.

Lisa McTigue Pierce

OK, thanks for explaining that.

Before we get into more on this and ask Trisha about when you’re switching from one packaging material to another, as well as how to best negotiate these days, let’s take a short break for a special message.

************************

Lisa Pierce here. Executive Editor of Packaging Digest. Have you heard?? SouthPack is back! After a break of seven years, the 2022 event will take place this year June 14-16 at the Charlotte Convention Center in Charlotte, NC. Owned and organized by Informa Markets Engineering, the parent company of Packaging Digest, SouthPack will be one of six co-located shows at the all-new IM Engineering South advanced design and manufacturing expo. Sign up today at imengineeringsouth.com. That’s I M ENGINEERING SOUTH dot com.

Now, let’s get back to our Packaging Possibilities podcast.

************************

Lisa McTigue Pierce

Trisha, today, a lot of brand owners are switching away from plastic packaging to other materials, paper for the most part, from a sustainability point of view. How is that conversion impacting the packaging sourcing market?

Trisha McRoberts (guest)

So in recent years, GSF has designed and opened several innovation centers, which serve as hubs for innovation that our customers, quality experts, nutritionists, chefs, food scientists, and regulatory specialists have direct access to. Every year we’re seeing the development of hundreds of new products and every time we do bring a new product to market, we’re looking at these packaging elements and what makes the most sense in this environment.

Consistently innovating every facet of our business is essential, and that includes packaging. Whether or not paper is a solution for that really depends upon the technical requirements to enable food that is safe and can manage through the end-to-end supply chain. The FlexPrep portion-dispensing pouch that I mentioned previously that has extensive recycling capability is an example that recently we have put in place and it’s really exciting because it has been following the protocols published by the Association of Plastic Recyclers.

And this package has been able to demonstrate compatibility with PE flexible mechanical, the mechanical recycling stream, reducing primary packaging by up to 85%. The FlexPrep portion-dispensing pouch has been a sustainable packaging option that we’re really quite proud of in the marketplace today.

Further, we’re onboarding a new resource as a senior packaging buyer who will continue to spearhead efforts to eliminate single-use plastic. This is really high on our list of objectives, and we know that today there is not a technical solution in the world that is executable. So it will take a team effort. Innovation is something that will, the partnerships will drive the results here. And so far we have implemented a number of solutions with other suppliers that give us reason to believe that we will be successful in solving for this one.

For example, you know, on the corrugated side, we currently are, have deployed 100% recycled material in our corrugated boxes and that is you know a great thing to leverage the MRFs or the Material Recovery Facilities that are near site to our locations that specialize in receiving, separating, and preparing municipal waste back into the paper that can then be converted into corrugated boxes that ship throughout our end-to-end supply chain. And I would say that, overall, we are committed to expanding the recycling infrastructure to ensure that more regions throughout the US and the world are able to deploy open and closed-loop recycling solutions that are sustainable.

Lisa McTigue Pierce

The corrugated recycling project that you mentioned … is that a closed-loop system for you where you’re using your own corrugated to then recycle into new boxes for yourself?

Trisha McRoberts (guest)

It’s actually more of an open-loop solution in that scenario.

Lisa McTigue Pierce

OK, great. Wonderful. So one of the things that I’ve been hearing from other brand owners … specifically on the food side … is that they are maybe rethinking the needs, the barrier needs of packaging and shelf life from a sustainability point of view. Is … and perhaps maybe reducing the amount of barrier and thickness to the packaging and maybe not get as much shelf life as they used to, but knowing that maybe they don’t need that much shelf life. Is that something that Golden State Foods is looking at as well?

Trisha McRoberts (guest)

I would say that we do look at it on occasion. Our number one priority is food safety and ensuring, you know … our products do turnover pretty quickly. So the extended shelf life that you see in some consumer goods on the shelf are less relevant to our particular category. That being said, I think targeted shelf life is really important to the sustainable solutions that we will be deploying in the future.

Targeted shelf life is really important to the sustainable solutions that we will be deploying in the future.

Lisa McTigue Pierce

OK. Thank you for that. So last question is, how can brand owners best negotiate with their suppliers today on availability, price, and delivery?

Trisha McRoberts (guest)

Well, negotiation is not just about price, but we are very focused on managing and improving our overall supplier performance in a sustainable manner. So as part of our creed and values at Golden State Foods, we’re focused on giving our customers a fair deal while maintaining the highest standards and focusing on the ultimate success of all partners. This includes cost and mitigation efforts that preserve high-quality production for our restaurant and retail customers and, in turn, the consumers who utilize the products.

This is how GSF pursues the mutual success of our customers, and we make our best efforts to, toward the attainment of our common goals. While strong supplier relationships have proven beneficial to the buyer and seller, these are not a replacement for the active and ongoing dialogue and managing our supplier relationships. So bidding cycles must be in place to make sure that total landed costs are competitive within the market environment.

And if we look at negotiation with more of a global lens and the big picture in mind, we want to ensure that everybody is having a win/win experience and that all sides are able to be sustaining the growth of their organizations while enabling innovative solutions for the marketplace. So, you know, our buyers are really focused on negotiating and establishing a performance framework early in the relationship to make sure that we have long and embedded relationships in place, and keep continuous improvement focus in mind.

So if we think about five areas that we’re focused on here: We want to understand the business mission and business drivers and how they connect to each other; think outside of the box related to price — there’s many different ways to take price out of a system without impacting the total cost of goods; and be authentic — so, you know, we really want to build credibility and trust and have long-term relationships and that are sustainable.

Finally, we work towards a positive outcome for all parties and create a plan that embeds evaluation and test evaluation and assessment as we are a continuous-learning organization and always want to bring out the best in others.

Lisa McTigue Pierce

Excellent. Sounds like a winning plan and I love the philosophy of it. Must be a win/win situation for the players who are involved because, quite frankly, that’s the only way that it can be a sustainable relationship and move innovation forward in the industry. We all know that.

OK. So I said that was going to be my last question, but I lied because I thought of something else. It sounds like a lot of what we’ve been talking about here has been on the packaging materials side of things. But does … do you get into the sourcing for packaging equipment and machinery? And how are we doing these days from a lead time point of view on that and not only for the full equipment, but also maybe for the replacement parts as well?

Trisha McRoberts (guest)

Yeah, absolutely. I think, you know, similar to all supply chains throughout the world, lead times are being extended for a variety of different reasons, whether that be manufacturing capacity, labor playing a role, or the ocean freight environment that we are operating within. So planning is critical. We do buy equipment on a regular basis, and we are experiencing extended lead times and so planning and having your critical parts have backups is an important part of the execution strategy.

Lead times are being extended for a variety of different reasons, whether that be manufacturing capacity, labor playing a role, or the ocean freight environment that we are operating within. So planning is critical.

Lisa McTigue Pierce

OK. Excellent, Trisha. Thank you so much. What a lot of wonderful advice, not just for food companies, but for any brand owners out there who are looking to improve their sourcing strategies. So thank you very much. Really appreciate your time.

Trisha McRoberts (guest)

Thank you, Lisa. Great to spend some time with you today. Take care.

About the Author(s)

You May Also Like