3 Reusable Packaging Perspectives from Popular Brands

Executives from The Clorox Co., Nestlé and entrepreneur Soapply share insights into the sustainability and cleanliness of reusable packages for products sold through Loop’s shopping platform, especially in a post-pandemic world.

June 10, 2020

Last year, recycling/upcycling firm TerraCycle launched Loop, a shopping platform for zero-waste-packaging products, with the support of some of the world’s biggest brands (see “Loop and big brands boldly reinvent waste-free packaging.”) Together, the eco-commerce provider and the brands have learned that there is indeed a market of consumers who will by Crest mouthwash, Tide laundry detergent, and myriad other products from Loop’s online store — then return their empty packages to be cleaned, refilled, and reused.

Since its early 2019 introduction, Loop’s business has grown from a direct-to-your-doorstep model with regional service to testing of mass-market retail partnerships to imminent national coverage. Retail partners include Kroger and Walgreens in the US market, Canada’s Loblaws, and the U.K.-based Tesco chain. Germany and Japan are on the horizon, too.

Turning to package design, appealing design and decor, convenience, and affordability are keys to all packaging. For reusable designs, add the challenge of environmental sustainability — along with economic viability. So far, it appears the fates have been kind to the optimists eyeing the platform a year ago (see “Packaging peers react to Loop’s daring reusable-packaging model”).

We asked leaders at three brands about their reusable Loop designs, from structure and decor to reusability issues and cleanliness — including how reusability, done right, bucks the trend of those who thought single-use packages would dominate design in the post-COVID age.

The packaging leaders participating are:

• Matthias Palm, research director, global packaging & sustainability, The Clorox Co.

• Steve Yeh, project manager with Nestlé’s Häagen-Dazs brand.

• Mera McGrew, founder, Soapply.

We start with Matthias Palm from The Clorox Co.:

For your Clorox Disinfecting Wipes 60-count package, what are the key aspects of the product, package type, material, or overall design strategy?

Palm: Our Clorox Disinfecting Wipes stainless steel canister is reusable, durable, sleek, and designed to make the move from “under the counter” to something that families can be proud to display in their home.

Why did you choose this particular package decoration technology for your Loop product?

Palm: We partnered with Kohler to optimize a ready-built package that they had designed and that would meet the packaging requirements for the Loop system. The choice of a minimalistic label complements the functionality of the easy-to-clean and refillable product design.

How hard or easy was it to find and work with a packaging supplier who could deliver this particular package, and what were your considerations in the selection?

Palm: Our success depends on the collaboration among Clorox people, our business partners, and our communities. In the case of Clorox Disinfecting Wipes, Kohler has been a great partner to work with to further drive sustainable innovation. Their Design for Environment Program ensures that sustainability is built into the product design process.

Additionally, our partnership with them enabled us the speed and efficiency to get our product from design to market in six months’ time.

How many (re)uses does the package have across its lifecycle of reuses — and how does this inform your package design and decorating method?

Palm: The stainless steel canister can achieve 100 reuses. We expect the present closure to last a minimum of 10 reuses.

We are working on improving the design in a couple of ways: We’d like the closure to be even more durable; and we’re simplifying the number of components to aid in ease of cleaning the product, and for more optimized dispensing.

For the next phase of expansion, we aim to improve the overall package to enable even more reuses.

What adaptations did you make to accommodate this design with the Loop platform, and why (or why not)?

Palm: It was a challenge to find the right seal to the stainless steel canister that would protect the product from leaking or evaporating. We tried several designs and varieties of materials, but initially came up short. But, in the Clorox spirit of acting nimbly and working resourcefully, we thought to utilize another Clorox product’s existing packaging technology, and that did the trick!

Can you discuss the package’s present and future use in low-volume “specialty” vs. high-volume, mass retail rollout?

Palm: Right now, our product is currently available through Loop’s ecommerce platform in the Mid-Atlantic region. However, as Loop expands its retail partner presence, we are looking to integrate our products into those stores as well. Our ultimate goal is to reduce waste and strive for innovative sustainable product solutions that our consumers love. Loop is a crucial partner in helping us achieve this.

How does reusability and your Loop initiative relate to the needs of your business and your customers as we progress through the COVID-19 situation?

Palm: Right now, the health and well-being of our employees, consumers and communities is our priority. As we try to keep our families healthy and safe, the need for Clorox Disinfecting Wipes has reached extraordinary levels. We are working around the clock to increase our supply and are committed to doing everything we can to support consumers, healthcare facilities and communities during this time.

Q&A with Steve Yeh, project manager with Nestlé’s Häagen-Dazs brand:

For your Häagen-Dazs ice cream in the 14 fl oz container, what are the key aspects of the product, package type, material, or overall design strategy?

Yeh: We created a beautiful, reusable package for Häagen-Dazs ice cream with rounded corners and a sleek, modern look. It also keeps the ice cream at a perfect temperature, which means it melts more quickly at the top to provide the perfect texture for scooping. In addition to the container itself, the team developed a cooler box system to fit inside the Loop tote bag that keeps Häagen-Dazs ice cream frozen for 24 to 36 hours. The cooler box system was designed by Loop.

Why did you choose this particular package decoration technology for your Loop product?

Yeh: The package design development was a critical part of the entire Loop process. We knew from the start we had to get the right people involved. It’s not just about making a reusable container — It’s also about creating a consumer experience and making a package that people will want to showcase in their homes and that they’ll enjoy using.

The Häagen-Dazs Loop package went through four major iterations, with the final version being the 15th iteration. We’re really happy with how people have responded to the design.

Consumer insights were another main driver of our design process. We know a lot of people eat their ice cream directly from the container, and we were concerned that holding a cold steel container wouldn’t be a good consumer experience. To solve for this, we created a double-walled container that allows the product to stay cold while still being comfortable to hold. Our team also rounded the corners to make it easier to scoop without leaving extra ice cream at the bottom of the container.

How hard or easy was it to find and work with a packaging supplier who could deliver this particular package, and what were your considerations in the selection?

Yeh: We worked with multiple packaging suppliers. One challenge was that this was Nestlé’s first entry into the “reusable” space, so we needed to work with reliable, already qualified suppliers. The final decision was based on both the ability to deliver a unique experience to the consumer as well as ensuring food safety through reuse.

How many (re)uses does the package have across its lifecycle of reuses — and how does this inform your package design and decorating method?

Yeh: We partnered with TerraCycle to develop proprietary cleaning technology that is critical to maintaining the quality and safety of the product. We expect the container to endure dozens of reuses/refills. The graphic design on the bottom portion of the package also were designed with flexibility and re-use in mind — this part of the container can be used across any flavor we might offer, while most ice cream containers have customized designs across the entire package that reflect the specific flavor.

What adaptations did you make to accommodate this design with the Loop platform, and why (or why not)?

Yeh: This was designed exclusively to use with the Loop program. It was not a modification to a previous design.

Can you discuss the package’s present and future use in low-volume “specialty” vs. high-volume, mass retail rollout?

Yeh: Since the launch of Loop, the Häagen-Dazs packaging has been offered in NYC-area Häagen-Dazs Shops locations, and we’re expanding to more than 200 Häagen-Dazs Shops across the US this year. On average, we’re seeing a 62% refill rate, and it’s as high as 160% in our best-performing location.

TerraCycle is working with Kroger and Walgreens to test an expansion of Loop in retail stores later this year. We are still evaluating the viability of a high-volume, mass retail rollout and have not committed to participating with TerraCycle in such a pilot.

How does reusability and your Loop initiative relate to the needs of your business and your customers as we progress through the COVID-19 situation?

Yeh: An interesting insight that we uncovered for our Loop e-commerce experience is that ice cream is consumed more quickly than other items sold on the platform such as household cleaners or detergent – and people don’t want to return their tote with just one or a few items. Having a retail presence gives people the option to return their pint as soon, and as often, as they want via stores. This addresses the need for a quicker turnaround while providing another touchpoint of interaction with the brand.

Our plans currently are to continue with Loop/TerraCycle in this journey. We plan on producing and will be ready to pivot with demand.

Q&A with Mera McGrew, founder, Soapply:

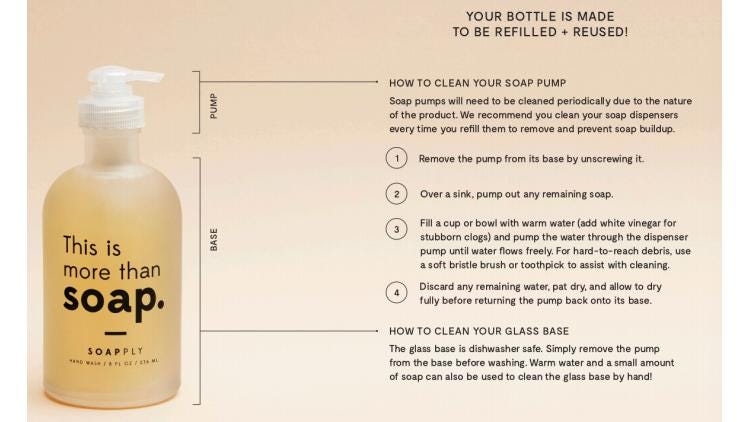

For your Soapply Liquid Hand Wash in the 8 fl oz jar with pump dispenser, what are the key aspects of the product, package type, material, or overall design strategy?

McGrew: Everyone needs soap. Soapply is more than soap. Simply put, Soapply is the best soap for you, your skin, our planet, and people around the world. Design-focused with the environment in mind, Soapply’s sink-side recycled glass bottles offer a minimalistic chic addition to your sink and are meant to be refilled and reused over and over (and over) again.

Why did you choose this particular package decoration technology for your Loop product?

McGrew: Soapply has always been bottled in recycled glass bottles. Every second, 20,000 plastic bottles are produced. Your soap shouldn’t come in one of them.

I care about the environment and our conscious consumers do too. Our recycled glass bottles allow our customers to help tackle the plastic problem from next to their sink. From the beginning, I was obsessed with what was in our soap (and what wasn’t) and how it was packaged. Soapply didn’t create new packaging for Loop.

When it came to designing Soapply’s sink-side soap bottle four years ago, we were concerned with three things: creating something that looked beautiful next to your sink, creating something that made a statement, and ensuring the product and packaging were safe for our consumers and our planet.

How hard or easy was it to find and work with a packaging supplier who could deliver this particular package, and what were your considerations in the selection?

McGrew: Soapply’s bottles are silk-screened, which ensures they continue to look great over time. We have worked and continue to work closely with the individuals who do our bottle decoration. Their skill, craftsmanship, and experience are invaluable.

How many (re)uses does the package have across its lifecycle of reuses — and how does this inform your package design and decorating method?

McGrew: Soapply’s sink-side recycled glass soap bottles are meant to be refilled and reused. With proper care, there is no limit to how many times you can refill and reuse your sink-side bottle!

What adaptations did you make to accommodate this design with the Loop platform, and why (or why not)?

McGrew: We always intended for our sink-side bottles to be refilled and reused. We launched with Loop three years after we launched Soapply. The reusability, sustainability, and quality standards we put in place for ourselves from day one have always been extremely high. So, when it came to on-boarding with Loop, our high internal standards meant we met all of Loop’s standards with our existing packaging — there was no need to evolve, adapt, or reinvent our packaging.

Can you discuss the package’s present and future use in low-volume “specialty” vs. high-volume, mass retail rollout?

McGrew: Soapply is already available in major retailers. The cost of producing packaging that is better for consumers, designed with the environment in mind, and created to last is obviously more expensive than single-use packaging.

However, consumers now realize that the actual cost of single-use packaging is greater than the price tag they see. Soapply offers a great product and an alternative to the dominant single-use plastic soap bottles lining most shelves.

How does reusability and your Loop initiative relate to the needs of your business and your customers as we progress through the COVID-19 situation?

McGrew: Soap and proper hand-washing are so important right now. We have seen our online business continue to grow overall month-over-month as the demand and need for soap has increased in light of the global pandemic. Like so many other businesses, we’re working hard to solve the challenges that have come our way and to continue to meet consumers where they are.

Right now, most consumers are at home. Offering shoppers a safe way to get their essentials delivered directly to their homes and with a reduced impact on the planet is a double win. It’s really exciting to see Soapply continue to be a best seller on the Loop platform.

The wrap-up: Loop ensures packages’ safety.

The high confidence brand-owners place in Loop’s safety and sanitation bodes well for the reusable packaging platform in light of public concern over COVID-19. Tom Szaky, Loop founder/CEO, offered these additional assurances:

“Neither single-use nor reuse packaging is inherently safe or unsafe — it’s how you deploy these systems. Consumer perception of reuse and how reuse is framed is massively important. People are used to reuse without even thinking about it; think medical industry or dentists. When you go to a dentist office, and you get your teeth cleaned, they’re using metal tools that were used on hundreds of patients before you. And if they didn’t clean that to a surgically sterile state, that could be putting you at massive health and safety risk. Right? And we’re all totally fine with it.

“Cleaning is what makes reuse safe or unsafe and Loop takes cleaning uber-seriously! Loop uses state-of-the-art cleaning facilities in France and the US, and when we launch in the UK, we will have a dedicated UK facility.

“Loop uses strong and robust cleaning processes. Pre-COVID-19 we were already protecting against other diseases and concerns — way more potent than COVID-19. Following COVID-19, we had to make no upgrades to our cleaning processes at all in terms of people or overall protocol.”

About the Author(s)

You May Also Like