3 steps to selecting the right LCA tool

September 19, 2014

Use this step-by-step guide to help identify which life-cycle assessment (LCA) tracking system will best fit your needs.

Heightened environmental awareness over the past decade has spurred increasing interest by both manufacturers and consumers in how products and their packaging—and the industrial processes behind them—affect the environment. And the interest in performing Life Cycle Assessments (LCA) of these environmental impacts, from the moment raw materials are extracted for production to when the goods become waste, has kept pace.

LCAs evaluate a number of environmental impacts of a product or a process throughout its entire life cycle (from “cradle-to-grave”). And today, a large number of LCA tools are available, from simple, web-based applications to more involved tools that often require trained specialists to run the analyses. With so many possible directions, how do brand owners, packaging designers and decision makers who need—or want—to use an LCA tool select the most appropriate application for their needs?

Step 1: Set your goal

The first step in the process is defining the overall goal of the analysis, and roughly scoping it out, since this will make it much easier to decide which exact processes to analyze, data needs and the right software to use.

For instance, since LCAs can be carried out for products, services or processes, one of the first decisions a company must make is what it wants to evaluate, such as the environmental impacts for one or more consumer products placed on the market.

Next, the company should identify the particular focus of the analysis it wants. For a consumer good, for instance, a company may decide to focus initially on the product’s packaging sustainability goals. By narrowing the scope of the review to just packaging, that decision also limits the number of tools available for that particular analysis, which can streamline software tool selection process and help reduce initial investment costs.

Later, the same company may decide to either upgrade its packaging-focused tool, if it offers such flexibility, to include additional impacts—such as environmental impacts of the product itself—or move on to a more complex analysis tool that helps perform a complete LCA of the product and the packaging.

Step 2: Define metrics of interest

Once an organization finalizes the main objective of the study it wants to perform, the next important step is to decide whether a more complete LCA approach is most valuable for the company at that time, or whether only one specific type of impact is of particular interest in certain circumstances. While performing a complex analysis of interrelated impacts on all Life Cycle Inventory (LCI)-specific metrics (water, energy, raw materials, and releases to air, land, and water) is a comprehensive way to map environmental impacts, sometimes a company may need to focus on a single metric, in which case a “footprint” analysis may be all that’s needed. For example, while a “water footprint” analysis is not an LCA (although an LCA will provide results regarding the water-related impacts), it may be all that a company needs to perform at a given time.

Step 3: Decide on the type of LCA

After identifying goals and metrics, a company is ready to choose the type of LCA technique they would like to use. The two main types of LCA methods, including their most appropriate uses, are as follows:

1. Qualitative LCA methods: Qualitative LCAs are sometimes also called “approximate” LCAs (although, in reality, no LCAs study is exact). For example, a qualitative LCA can analyze environmental effects based on metrics and procedures agreed upon by stakeholders who are interested in a brief overview of changes made in certain situations, such as the impact of reducing the weight of a packaging system at each life stage. The results (in this example, from data gathered from participants in each stage) are generally used as benchmarks to track improvements over time or to inform future decisions, but they are by no means extensive or comprehensive.

On the other hand, complex qualitative LCAs, performed by specialists using only impact tables (such as emissions or toxicity) that are publicly available for various processes, are very involved—and are therefore heavily dependent on the expertise of the professionals performing them. While unlikely to be used for any type of reporting to third parties, these analyses can help companies “red flag” certain elements, such as substances in products and packages, and consider reducing or eliminating them from the life cycle.

Although standards exist (ISO 14040/44) that give guidance on general requirements for running a complete LCA study and reporting on its results, evaluating the environmental impacts of a product or process remains, in practice, somewhat of an art that relies on the skill and experience of the specialist performing the analysis. As a result, many companies prefer to use quantitative LCA techniques.

2. Quantitative LCA methods: The methodological framework for quantitative LCA techniques is based on ISO 14040/44 standards and are, therefore, used by companies who want to use LCA results for specific claims regarding the sustainability improvements of their products or packages. When an organization needs a quantitative LCA, decision makers can choose either a full LCA or a streamlined ISO-based procedure—and a number of tools are available on the market for either approach.

• Full Life Cycle Assessments. These assessments are used by companies interested in a range of impacts on the environment by both their products and packages. The results of these studies are the most detailed and close to the actual impacts on the environment and are best used during the design phase to make the best possible choices of materials, layouts, messaging and more. However, they can be costly, require extensive data and take longer to complete.

• Streamlined Life Cycle Assessments. To help reduce the costs, data and timeframes a full LCA can require, the LCA community has created ISO-based LCA techniques that streamline the processes. These options can include tools that only analyze packaging life cycles (instead of products, packages and industrial processes all in one) or tools that eliminate certain life-cycle stages, use industry averages or publicly available databases for certain data, and eliminate detailed recommendations or interpretation of results. These tools can be used for a valuable first-time assessment or an assessment of just packaging, for instance. With enough transparency about the assumptions used, they can represent a quick and simple way to make certain design decisions.

Spending the time to consider the basics upfront can be valuable in saving subsequent difficulties in running these studies. Once a company works through these initial steps, decision makers will be ready to move forward with researching the availability and reliability of various tools or experts that can help them run LCAs for their specific needs.

Gabriela Dobrot is a principal consultant at Environmental Packaging Intl. (EPI), a consultancy specializing in global environmental packaging and product stewardship requirements. Contact her at 401-423-2225 or [email protected].

Tools for packaging-related life-cycle assessments

Learn more about these popular LCA tools for packaging:

Streamlined LCA Tools:

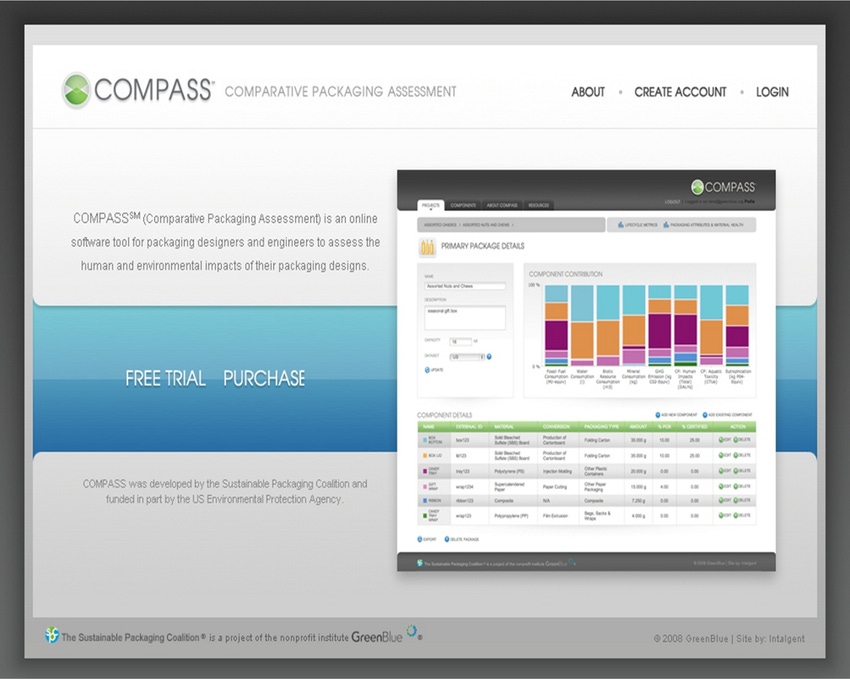

COMPASS (Comparative Packaging Assessment) from the Sustainable Packaging Coalition

EIO-LCA Calculator

PIQET (Packaging Impact Quick Evaluation Tool) from the Sustainable Packaging Alliance (Austrialia)

Full LCA Tools:

GaBi

www.gabi-software.com/america/index/

openLCA

SimaPro

About the Author(s)

You May Also Like