Analyzing the Advanced Recycling Sector

Research from nova-Institute investigates 127 technologies and the providers pushing advanced recycling forward.

At a Glance

- More than 340 advanced recycling plants are installed or in planning stages worldwide

- By 2027, Europe’s advanced recycling input capacity will more than triple, and global input capacity will double

- Dissolution, solvolysis, pyrolysis, gasification, and enzymolysis technologies and providers come into focus

An updated and expanded report on advanced recycling from nova-Institute, Hürth, Germany, explores technological advances, identifies key companies, and provides a view into the current state of advanced recycling in Europe and worldwide.

The report offers a structured overview of the advanced recycling landscape, defining the technologies and profiling providers of advanced recycling — particularly chemical recycling.

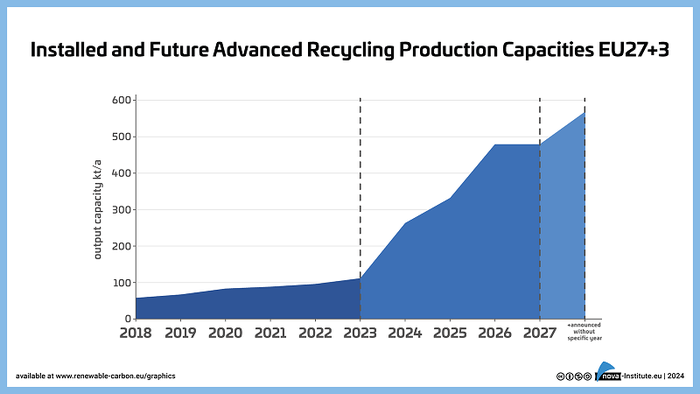

The report maps more than 340 planned and installed advanced recycling plants worldwide, with the majority in Europe; total input capacity is 1,477 kilotonnes/1,628 kilotons per year. Europe’s input capacity is expected to more than triple by 2027. Globally, input capacity is expected to double by 2027.

On the output side, global production capacity for advanced recycling is 1,082 kilotonnes/1,182 kilotons per year. Products include polymers, monomers, naphtha, secondary valuable chemicals, fuels, and energy.

A range of advanced recycling technologies.

Advanced recycling includes technologies suitable for plastic waste streams of various compositions and quality. The technologies are used to transform the waste into a range of raw materials for reintroduction into the plastics value chain.

The report provides an overview and classification of the technologies and providers, presenting 127 advanced recycling technologies that are currently available or will be in the near future.

The technology categories include:

Dissolution

Solvolysis

Pyrolysis

Gasification

Enzymolysis

Dissolution is a technology that uses solvent to dissolve targeted polymers from mixed plastic waste, keeping the polymer’s chemical structure intact. Other plastics components such as additives, pigments, and fillers do not dissolve and can be separated from the dissolved polymer. An anti-solvent is used to precipitate the target polymer from the clean solution. No polymerization step is required, in contrast to solvolysis.

The report indicates that current maximum capacity for the dissolution method is 8,000 kilotonnes/8,818 kilotons per year, with most of the technology providers located in Europe, North America, and China, respectively.

Solvolysis, which is also solvent-based, is used to depolymerize polymers, primarily polyethylene terephthalate (PET), into building blocks such as monomers, dimers, and oligomers. After depolymerization, the building blocks are separated from additives and other plastic components, and the cleaned building blocks are repolymerized.

Some 24 companies use solvolysis technology, with most located in Europe, North America, Japan, and China, respectively.

NOVA-INSTITUTE

Pyrolysis is a thermochemical process that converts mixed plastic waste (mainly polyolefins) and biomass into liquids, gases, and solids using heat, under anaerobic conditions. Products of the conversion include oils, diesel, naphtha, and monomers, plus syngas, char, and waxes. Some of the products can be used as feedstocks for production of new polymers.

Pyrolysis has an annual global capacity of 40,000 kilotonnes/44,092 kilotons, and most providers are in Europe and the US.

Gasification is also a thermochemical process. It is used to convert mixed plastic waste and biomass, in the presence of heat and oxygen, into syngas and carbon dioxide. The researchers have identified 12 gasification technology providers; currently the largest capacity achieved is 200,000 kilotonnes/220,462 kilotons per year. Most providers are in North America and Europe.

Enzymolysis is a biochemical process that uses biocatalysts to depolymerize polymers. This technology is still in early development and is available only at laboratory scale.

In addition to profiles of companies that provide these advanced recycling technologies, the report looks at six providers of pre- and post-processing technology. Their solutions include feedstock pre-treatment prior to advanced recycling and the conversion of secondary valuable materials into chemicals, materials, and fuels.

About the Author(s)

You May Also Like