Dell introduces packaging made from bamboo

January 30, 2014

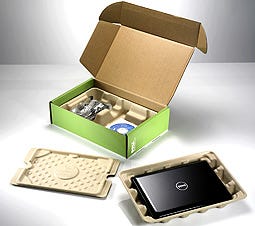

Dell computer bamboo packaging

Dell will begin shipping its Dell Inspiron Mini 10 and Mini 10v netbooks in packaging made from bamboo, a highly renewable material that serves as a great alternative to molded paper pulp, foams and corrugate often used in packaging.

Dell is using the material for the product cushions cradling the Mini inside an outer box made from 25 percent post-consumer materials. The company plans to expand its use of bamboo packaging to more products in early 2010.

This innovation is the latest expression of Dell’s commitment to minimizing its impact on the planet and making it easy for customers to do the same.

Why Bamboo?

It grows fast. Bamboo, a member of the grass family, is among the fastest growing woody plants in the world. It can grow up to 24 inches per day and reaches full harvesting maturity in three to seven years, significantly faster than hardwoods.

It’s strong. Remarkably, bamboo’s tensile strength is similar to that of steel, making it a reliable material for protecting technology equipment in transit.

It’s easy on the environment. Bamboo helps promote healthy soil. The plant’s deep root systems protect against land erosion, and when harvested correctly, it doesn’t require replanting after harvest.

Dell bamboo packaging

Ensuring SustainabilityDell is working with bamboo packaging supplier Unisource Global Solutions (UGS) to ensure all processes associated with the bamboo’s production meet the highest standards. The company sources its raw bamboo from a forest that follows Forest Stewardship Council (FSC) principles and criteria. The bamboo forest is located in China’s Jiangxi Province -- far away from pandas’ known habitats. Dell is also working with UGS to secure FSC-certification for the bamboo’s full chain of custody, from the forest to the manufacturing facilities.

Dell, Georgia Pacific, UGS and Environmental Packaging International are also in the process of certifying the packaging for recycling.

The Three C’s of Smarter Packaging

In December 2008, Dell announced a plan to revolutionize computer packaging. By 2012, Dell aims to reduce packaging volume by 10 percent; increase the amount of recycled content in packaging by 40 percent; and increase the amount of materials in packaging that’s curbside recyclable to 75 percent. To achieve these goals, the company is implementing a strategy based on the three C’s:

Cube: How big is the box? Could it be smaller?

Content: What is the packaging made of? Could it be made of something better?

Curb: Is it easily recycled?

"The use of bamboo for electronics packaging is pretty new, but its viability as a great packaging material can’t be ignored," said Oliver Campbell, Dell’s senior manager of packaging worldwide. "We’re introducing it with mobile products, as it’s proven a strong, sustainable and cost-effective solution for packaging those. We’re actively working to integrate this and other innovative, agricultural materials into packaging for products across our portfolio."

SOURCE: Dell

About the Author(s)

You May Also Like