Dow and P&G Partner on Dissolution Solution

Polyethylene is the target polymer of a novel recycling technology for hard-to-recycle plastic packaging.

April 9, 2024

At a Glance

- New recycling process will harness dissolution technology

- P&G will use the resulting PCR polymer to produce new packaging

- Recycling process will reduce GHG emissions

Dow and Procter & Gamble (P&G) are teaming up to create a proprietary dissolution-based recycling process for hard-to-recycle plastic packaging. Recovered polyethylene will be made into new packaging for P&G products.

The project’s goal is efficient conversion of plastic packaging waste into post-consumer recycled (PCR) polyethylene (PE) with low greenhouse gas (GHG) emissions. The companies will leverage their combined recycling expertise and intellectual property under a joint development agreement.

Waste to be recycled will include post-household rigid, flexible, and multilayer packaging made from a range of plastic materials, with a focus on PE. The output will be near-virgin quality PE suitable for packaging applications.

“The addition of [our] dissolution process to the range of recycling technologies practiced today presents a key opportunity to increase the amount of recycled plastic usage,” says Dave Parrillo, vice president of research and development, packaging & specialty plastics and hydrocarbons, Dow.

“The dissolution process works by using a solvent to separate targeted polymers and impurities in complex plastic materials. In this collaboration, the targeted polymer is polyethylene. Once separated, the polyethylene material can be extracted for recycling into new applications,” Parrillo adds.

“This process is closer to mechanical recycling than it is to advanced recycling, given that molecular bonds are not broken in the process,” he explains. The dissolution process is not considered chemical recycling, as there is no fundamental alteration to the molecular structure of the target polymer during the process.

P&G expects to eventually use the project’s PCR polymer to make new packaging for its products.

“This innovative PCR polyethylene has the potential for a number of different packaging applications where we currently use polyethylene,” says Lee Ellen Drechsler, PhD, senior vice president, platform innovation, corporate R&D, Procter & Gamble, noting that it is too soon to identify specific packaging applications.

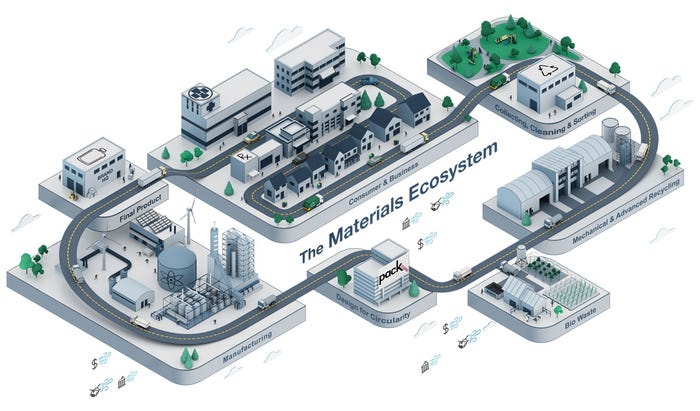

Rendering of plastics packaging circularity. DOW

Sustainable spotlight on circularity and GHGs.

Limiting emissions is a fundamental part of the project. “The goal of our process development effort is to achieve GHG emissions below virgin PE or lower than alternative advanced recycling technologies,” Parrillo says. “Mechanical recycling is expected to be the lower bookend for the GHG emissions.”

In addition to bringing their patented recycling technologies to the new partnership, Dow and P&G both bring materials science, manufacturing, and supply chain management expertise — all crucial to developing a circular recycling process that can be commercially scaled.

“At present, the development is at an early and conceptual stage,” says Parrillo. “As with all transformative innovation programs, the timeline is highly variable and dependent upon many factors.”

He adds, “Our common goal is to accelerate this process’s development to positively impact materials circularity across the industry.” Dow and P&G are currently considering a plan to license the technology.

The project highlights the importance of circularity to both companies. Dow has a Transform the Waste target of commercializing 3 million metric tons/3.3 million tons of circular and renewable solutions by 2030. P&G has doubled its use of recycled resin in the past five years and is aiming for all its packaging to be recyclable or reusable 2030.

You May Also Like