New cell phone package improves visibility and sustainability

January 30, 2014

|

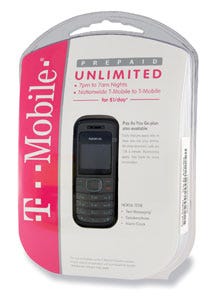

Today's retail environment demands quick turnaround—packaging designs included. That's why T-Mobile and Motorola USA have redesigned the packaging for a Motorola pay-as-you-go cell phone for T-Mobile, with an attention-grabbing design that Motorola anticipates will be better for the environment.

With help from Alloyd Brands, a strategic business unit of Tegrant Corp., Motorola, Libertyville, IL, designed and produced the new T-Mobile package with a booster shot in shelf presence while still maintaining tamper-evidence. But the new package does one better by significantly reducing materials.

The prepaid phones come in a kit that includes a wireless phone, starter airtime, a battery, a charger, and a hands-free headset. The user may refill minutes whenever they need more.

|

With a nationwide market debut in April in stores that include Walmart and Best Buy, the new package is mostly paperboard, says Tegrant's Rob VanGilse, director of marketing and business development. The new design replaces a clamshell and features specific changes that allow it to effectively interlock, back-to-back, in shipment, for maximum use of space in shipping cases.

The new package also cuts down on the use of plastic materials. It's made using Natralock® blister-cards and recycled PET thermoformed blisters, which reduce the amount of PVC used by 45 percent from the earlier clamshell. The package also saves 40 percent in transport materials and helps boost production rates by 20 percent, according to VanGilse, because the paperboard cards seal faster.

Alloyd Brands Printed Products designed the new package and thermoforms the blister, It also offset prints the packaging in four colors and two special colors with bold graphics on a green color scheme. The front card is folded over the top; the insert piece is visible through the back blister.

The .020 Natralock board is produced by MWV. An internal graphic card backing made of .014 Artcikote SBS (containing 30 percent post-consumer-recycled content) is also included in the new package structure.

Natralock can be sealed on existing machinery, so there was no need for Motorola's copacker, Cinram Intl., Inc., to buy new equipment.

The phones were loaded on semi-automatic packaging lines that use existing radio-frequency sealing equipment, VanGilse tells PD. The sealed card prevents in-store removal of the plastic blister, and Natralock's properties also prevent tearing. All of this added up to a win-win situation for the Motorola phones.

Motorola indicates that the transition from the plastic clamshells to the new packaging with Natralock was smooth and the benefits have added up for consumers, too.

More information is available: |

Alloyd Brands/Tegrant Corp., 815/787-5202. www.alloyd.com |

Cinram Intl. Inc., 416/298-8190. www.cinram.com |

MeadWestvaco (MWV), 804/327-5200. www.meadwestvaco.com |

About the Author(s)

You May Also Like