Container closure integrity testing through mass extraction 20493

Ensuring pharmaceutical products and medical devices are sterile and free of contamination is a dividing line between meaningful treatment and harmful disservice. This concept applies to nearly every section of the medical device and pharmaceutical realm. In this battle for sterility, packaging integrity should be a chief focus. A package with a breach will not act as a sterile barrier, and the product contained within may reach the end user in a contaminated condition.

August 10, 2017

Andrew Manrique

By Andrew Manrique, CPLP (ISTA), Packaging Engineer, Nelson Laboratories LLC

Due to the high risk associated with a contaminated product, manufacturing companies spend significant time, money, and resources on creating and testing functional packaging. One of the most important integrity tests is container closure integrity (CCI). CCI testing meets the integrity requirements outlined in ANSI/AAMI/ISO 11607-2:2006/(R)2015 Packaging for terminally sterilized medical devices-Part 1 and is recommended not only during the design and manufacturing process, but also during product revisions, batch releases, and when changes occur to the shipping, distribution, and storage conditions.

CCI testing has evolved from more probabilistic methods of testing (i.e., microbial immersion and UV/Vis) to more deterministic methods that yield empirical data that can be statistically analyzed. While the probabilistic methods served to give pass/fail criteria, they lacked in several key areas. The tests were often not reproducible and were highly subject to human speculation and error in the determination of the results. The tests are also destructive, which limits the ability of the manufacturers to investigate detected failures. For these reasons and others, the U.S. Pharmacopeial Convention (USP) created a guide for manufacturers to properly select emerging and preferred deterministic methods to meet the integrity requirements. The document, USP <1207> Package Integrity Testing in the Product Life Cycle, outlines both the need for change both in testing methodology and in determining which new testing methods are suitable for particular scenarios.

According to USP <1207>, “Testing product for sterility is a poor measure of product-package integrity and also will not ensure product-package integrity over the shelf life of the product when performed as a part of the stability program. In addition a package may be in no danger of microbial ingress and yet be unable to maintain the gas headspace content necessary for product quality.” The document goes on to say, “Validated package integrity test methods using technologies such as those described in this chapter are more sensitive and reliable than product lot sterility testing for detecting a breach in package integrity that could lead to sterility loss or failure in relevant product physiochemical quality attributes.” This modality of thought is starting to lead the industry toward more deterministic methods of CCI testing. This move has the advantage of taking into account the ingress of microbial contamination as well as other environmental factors, such as protection of pharmaceuticals sensitive to oxidation.

While USP <1207> outlines the various deterministic CCI methods available, it concludes that a one-size-fits-all solution does not exist. Each method has strengths and weaknesses that lend themselves to various packaging and drug product configurations. Despite this, some methods appear more attractive based on their flexibility to test many packaging arrangements with a higher sensitivity. As with most scientific endeavors, the medical and pharmaceutical industry advances using scientific method and impartial testing. The industry looks to take as much human bias out of the testing and understanding of processes and technologies as possible. The microbial immersion and dye immersion (UV/Vis), probabilistic methods, do not suitably fit this model. As technology advances, many new options become available such as high voltage leak detection, pressure decay, vacuum decay, laser-based headspace analysis, tracer gas detection, and so on. The release of the current USP<1207> outlined the importance of testing, where each method both succeeded and failed, and helped the manufacturer make an informed decision on which technology to use.

While each of the prior methods mentioned have merit, when all attributes are mapped out and weighed against one another, there is a clear choice for CCI testing: mass extraction. Mass extraction allows for a nondestructive, highly sensitive, industry-recognized test regime with a quick turnaround time. As medical device designers and manufacturers know, the design process can take many meandering twists and turns as problems are identified, solutions rendered, and testing performed for validation. While in an ideal world there would be a perfect design the first try, with only one run of testing to validate, reality often is quite to the contrary. Each potential issue creates another round of testing and process modification must be undertaken. Improving the time and accuracy of testing greatly accelerates this process. Quick turnaround means the time it takes to move the product from design to manufacture is greatly reduced, lowering overall cost. Therefore, it is of great importance to choose testing and validation methods that best suit your product and accelerate its design and validation cycles.

Mass extraction embodies a great balance between the many considerations and requirements of the diverse medical/pharmaceutical industries. This test is extremely sensitive and can detect leaks to a sensitivity of two microns. CCI testing is generally applicable to rigid and semi-rigid containers that contain a drug product. Examples include, but are not limited to:

Auto-injector pens.

Syringes preloaded with drug product.

Eye dropper-style packaging.

Screw cap bottles.

Crimp cap vials.

Glass ampules.

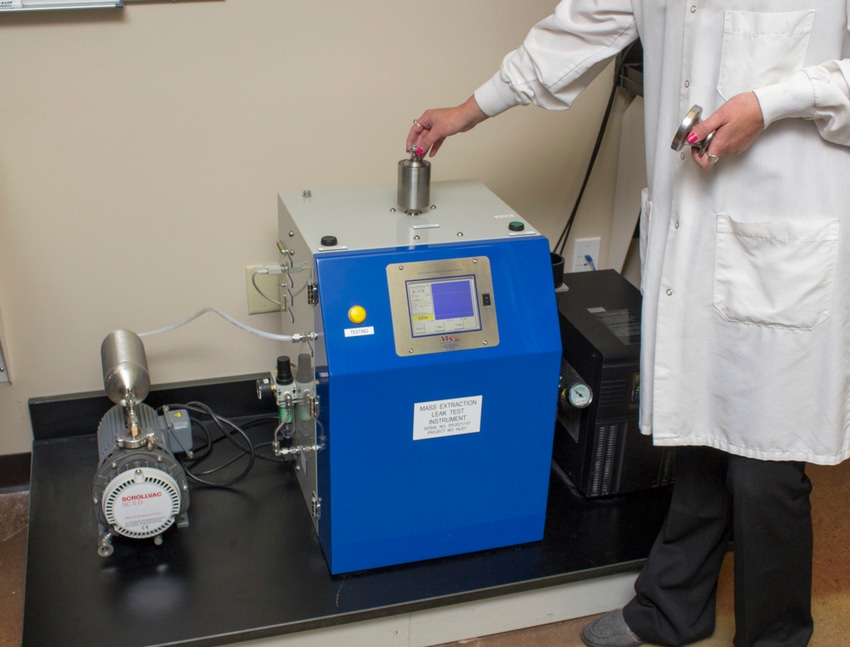

Using a specialized scroll pump, able to draw a vacuum below 1 torr, the mass extraction unit creates an environment where liquids exist below their phase transition point. In other words, if there is a liquid contained within the package and a leak exists, the liquid will quite literally “boil off.” Gas (either from the product or the headspace) on the interior of the package will exit through the defect, and this “mass” will flow from one portion of the test equipment to another. This flow of molecular mass will be detected by the highly sensitive “Intelligent Molecular Flow Sensor.” The mass flow sensor will determine the amount of mass flowing over a given period of time. It will then compare this data against a known product without a leak, and to one with a simulated leak. If the test does detect a mass flow, and it is of similar value to the known defect, a failure of integrity is noted. As can be seen below, there are many positive attributes that lend themselves to choosing mass extraction as a testing method for CCI.

Two-micron defect size sensitivity - Utilizing mass extraction, it is possible to detect defect sizes as small as 2 microns. This is more than twice as sensitive as many of the other technologies available. To better envision how small this measurement is, take into consideration that a human hair has an average diameter of 100 microns, and pollen has an average diameter of 30 microns.

Deterministic and quantifiable - Deterministic methods are less subject to error and provide data that can be statistically analyzed. This is in contrast to probabilistic methods that are subjective and do not provide data with high certainty.

Diversity - The new testing method can be used to detect leaks in a wide variety of container styles and compositions. In many systems, container rigidity, lack of headspace, conductance of the product, and other factors pose serious limitations on the detection of leaks. This is not the case with mass extraction, which can handle either rigid or semi-rigid containers, both liquid and gas-filled containers, containers of various package types (such as syringes, auto injectors, vials, ampules, etc.), and more.

Nondestructive - When a failure does occur and a leak is detected, it is difficult to inspect and diagnose the leak or leak cause when the method of testing is destructive. With mass extraction, the package under test remains intact allowing for investigative measures to be taken.

Rapid Testing - Each unit under consideration can be tested in seconds (minutes in some extreme cases). This is in stark contrast to methods like bacterial immersion (Microbial Challenge by Immersion), which can take up to three weeks to complete. Mass extraction eliminates the need for preparatory processes that are often lengthy and consume unnecessary resources.

Early Large Leak Detection – Container leaks that are significantly larger than the target sensitivity level are detected very early in the test process. This results in a short test time for containers that include gross defects.

Nonrigid Containers – Mass extraction now has the ability to handle non-rigid (flexible) containers (e.g., IV bags).

When all is said and done, manufacturers, medical professionals, and testing facilities have one primary goal: the safety and well being of the patients that their products and services will treat. With the health and safety of patients being at the forefront of our minds, it is of no wonder that we look to choose the highest-quality materials, methods, and tests available. Mass extraction exemplifies these traits and will play an increasingly significant role as the medical industry grows and matures.

Andrew Manrique, B.S., CPLP (ISTA), serves as Packaging Engineer, Study Director II, for Nelson Laboratories LLC, a Business Unit Of Sterigenics International.

Be sure to visit Nelson Labs at MD&M Minneapolis Booth #2128 November 8-9, 2017.

About the Author(s)

You May Also Like