7 ecommerce packaging bombshells in 2018

News about egroceries, a case for branding, the pros and cons of ecommerce repacking, and Amazon (x4!) prove that online is where the action was at in 2018.

As consumers and businesses do more and more shopping on their laptops, tablets and phones, the need for products—including refrigerated or frozen groceries—to be shipped in packaging optimized for this channel increases.

Here are the top seven ecommerce-packaging-related articles that were posted on PackagingDigest.com in 2018, based on number of page views from our worldwide network of packaging professionals.

7. Report delivers the goods on the egrocery packaging market

Mega-packaging supplier Tetra Pak focused its annual Index study for 2018 on growth and opportunities around egrocery. The research revealed four omni-channel packaging trends:

1. Convenience: This will be the main driver for online consumer take-up, as time-crunched consumers look for new ways to make their life easier. Key opportunities include easy product replenishment, voice ordering and convenient packaging.

2. Sustainability: Pressure on plastic and awareness of the circular economy will continue to grow, and recycling will become ever more important. Consumers want to know whether brands are “doing the right thing.”

3. Personalization and uniqueness: Customization of products and personalization in the consumer journey will be important differentiators going forward. This is accelerating the direct-to-consumer trend and as many as 80% of consumer packaged goods companies are predicted to migrate to this model by 2025.

4. Technology and performance: Super-fast delivery in as little as 10 minutes is expected by 2025, changing consumer behavior to buy more frequently and in smaller amounts, adding more complexity to the logistics. Supply chains will continue to be transformed by a raft of technologies, notably radio-frequency identification (RFID) and robotics, boosting efficiency and transparency.

Download a free copy of the report by clicking here.

NEXT: Solving the repacking problem

6. Ecommerce repacking: Necessary evil or godsend?

When consumers order a product online, it more often than not arrives in the same packaging seen on brick-and-mortar store shelves—just inside a shipping box. When fulfillment houses (Amazon, for example) do any additional packing (like wrapping a product in cushioning), they charge the brand owner a fee for “repacking.” That can get costly and, honestly, isn’t the most effective in protecting the product on its way to the customer. The whole process is inefficient, costly and not sustainable.

To fix the repacking problem, consumer packaging expert Michele Barone of PA Consulting Group shares seven provocative ideas.

Incremental solutions:

1. Reduce the amount of material in the secondary case through more efficient designs to cut repacking costs by approximately 10%.

2. Design cases for easy and efficient repacking, which can save material and labor costs by 25% to 30%.

3. Consider returnable packaging, which could eliminate repacking material costs. Returnable cases can incorporate sensors and connectivity features to monitor product, and environmental and location data—generating more efficiency throughout the supply chain to offset higher initial costs.

Transformational solutions:

4. Invest in flexible packaging equipment that could effectively handle a range of pack formats, reducing or potentially eliminating the need for repacking.

5. Consider a distributed packing model. This method breaks down the packing process into multiple stages, which are completed as the product goes through the supply chain. For example, companies could ship semi-finished cases and add products or print to the case at a warehouse close to the final destination.

6. Eliminate corrugated cases. If the primary pack is strong enough, products can be connected using adhesives, bands and tapes.

7. Design for omni-channel. The approach can focus on developing formats suitable for multiple distribution channels, or innovative ways of building product collations without the need for repacking. The challenge is to identify a single pack design that is able to fulfill a complex set of requirements from retail and ecommerce distribution and consumer across all touchpoints.

NEXT: Nestlé weighs in on the question of “branded” ecommerce packaging

5. 4 reasons branded packaging is vital in an ecommerce world

Amazon’s senior manager of packaging – sustainability Brent Nelson says brand owners don’t have to go to extremes with what he calls expensive “romance” design aesthetics because ecommerce sales aren’t as dependent on the package’s shelf impact like they are in physical retail stores. That’s true.

But Walter Peterson, packaging sustainability manager at Nestlé USA, and sustainability guru Bob Lilienfeld see other reasons why branded packaging is vital for products sold online.

Here are their first two:

1. If it were not for brand identity, graphics and messaging, customers might not choose your product from the sea of available products on a webpage, which could be the consumer’s first point of online interaction with your brand.

Key point: The package doesn’t merely protect the product, it protects the brand.

2. When consumers get the shipment and open the box, the best signal for confirming that they received the right product is that the package inside matches what they saw and purchased online.

Key point: The quality of the primary package directly confirms and reinforces the value of the product(s) it contains.

Read the last two points by clicking the headline above.

NEXT: The Amazon Effect

Not surprisingly, the top four ecommerce-packaging-related articles in 2018 on PackagingDigest.com all involve Amazon, the ecomm leader in most of the world. The company has been pretty active this year in working with the packaging industry on solutions that are optimized for Amazon’s fulfillment centers and for small-parcel shipping. Benefits of optimized packaging designs for ecommerce, according to the A to Z etailer, are:

• An improved consumer experience;

• Minimal negative impact on the environment;

• Lower “delivered” costs.

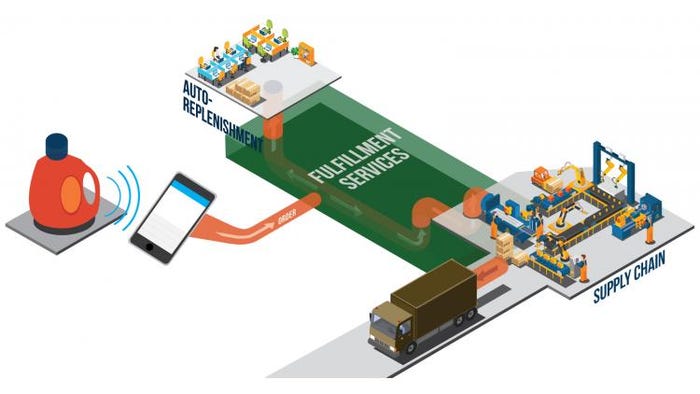

4. Smart packaging helps boost Amazon’s auto-replenish service

Auto-replenishment is the bomb in ecommerce! And Amazon’s Dash Replenishment Service—which provides consumers unprecedented convenience for automatic product ordering—now interfaces directly with smart packages from Jabil Packaging Solutions. When products are running low, the “connected” containers sense that and trigger a new order from Amazon.

3. Packaging analysts applaud Amazon’s new incentive program

Shortly after Packaging Digest broke the news of Amazon’s new Frustration-Free Packaging Vendor Incentive Program (see #1 below), we reached out to six packaging experts to get their opinions. All had mostly positive things to say:

Brian Wagner, co-founder and principal, PTIS LLC: “This will likely be the ‘kickstart’ that many companies needed to truly design packaging for the ecommerce channel.”

Matt Dingee, co-founder and chief operating officer, OnPoint2020: “Brands will discover that there are many sustainability and business benefits beyond compliance.”

Nina Goodrich, director, Sustainable Packaging Coalition, and executive director, GreenBlue:“Amazon has shown that it is possible to approach packaging differently. It has redefined the ‘job that packaging is hired to do.’”

David Luttenberger, global packaging director, Mintel: “Amazon considers itself to be a sustainability company, not an ecommerce retailer or logistics/distribution company. Everything it does reflects that mindset, and its package testing protocol is just one facet of a multi-faceted plan to prove that day by day, package by package.”

Jonathan Quinn, chair of AMERIPEN Ecommerce Working Group and market development manager, Nova Chemicals: “While design incentivizes are a step in the right direction, there are other system challenges that need to be taken under consideration as we seek to incorporate sustainability into the design of a sustainable ecommerce packaging system.”

Bob Lilienfeld, principal, Robert Lilienfeld Consulting, and editor and publisher ofThe ULS (Use Less Stuff) Report: “Amazon has pushed its program closer to where the logical decision makers have influence: supply chain management.”

Packaging Digest wants to know what you think too. CLICK HERE to take our quick poll now.

2. How Amazon developed a leak-free trigger sprayer

Working with closure manufacturer Rieke Packaging, Amazon solved one of its trickiest problems: Preventing liquids—even those with minimal product viscosity—from leaking during distribution in the small-parcel environment, where packages could be oriented in any direction at any time in their journey.

Rieke’s new Ultimate-E (ecommerce) trigger sprayer hits on three critical criteria:

1. It eliminates leaks, rather than simply reduces or contains them.

2. It maintains customer convenience because there are no inner seals to remove, meaning the product arrives ready to use.

3. It allows consumers to remove the closure—to refill the bottle, for example.

1. Amazon incentivizes brands to create Frustration-Free Packaging

In my opinion, our #1 ecommerce packaging article is the biggest news of the year because of its significance and potential for dramatic positive change in ecommerce packaging.

If you haven’t heard by now…

To help reduce packaging waste and improve efficiency of ecommerce shipping for its vendors, Amazon will require that select products being sold and fulfilled by Amazon arrive in its fulfillment centers in certified packaging under its Frustration-Free Packaging (FFP) program. This means that the packaging does not require any shipping preparation or an overbox to be applied.

The incentive? For each stock-keeping unit (SKU) arriving in certified FFP by the 2019 deadlines—Aug. 1 for the U.S. and Canada, and Oct. 1 for six European Union countries—Amazon will give vendors a one-time credit of $1. After the compliance deadlines, every product not in certified Frustration-Free Packaging will be charged a $1.99 fee.

I agree with Wagner’s assessment above in #3. Can’t wait to see all the new, ecommerce-optimized packages you guys are working on now.

********************************************************************************

In addition to leading suppliers showing the latest solutions in labeling, automation, food packaging, package design and more—WestPack 2019 (Feb. 5-7; Anaheim, CA) gives you access to the industry's leading educational offerings with the 3D Printing and Smart Manufacturing Innovations Summits, the MD&M Medtech Conference and free industry education at the Expo. Register to attend today!

About the Author(s)

You May Also Like