Totino’s pizza and packaging: Square, hip and supply-chain optimized

Square is hip when it comes to efficiency in packaging in this case study analysis of Totino’s bold move to a square pizza that piles on the supply-chain savings.

Deep at heart, I am a child of the 80’s. One of the top songs from that time—“Hip to be Square”—was generated by one of my favorite bands, Huey Lewis & the News. Now that I’m a packaging engineer, it looks like history is repeating itself: Totino’s is making sure it’s hip to be square as they just launched a new square pizza!

I don’t know about you, but when I hear “square pizzas” I immediately think of food service school lunch pizza. But apparently the budget food manufacturer (now owned by General Mills) did its due diligence on long-term packaging inefficiency and has realized the significant supply chain savings tied to square pizzas.

While traditional round pizzas poorly utilize cubic space, Totino’s wants its square party pizza to fit in

Years ago the Walmart Scorecard began to evaluate the “selling unit cube utilization” (SUCU, for short). This SUCU metric looked at the ratio of how well the product fit inside its respective packaging (product volume vs. package volume). When you evaluate the amount of air space and the cubic utilization of a round pizza in a square box, this shape change seems like a no-brainer. And in the transportation and warehousing world (not to mention cold-chain transportation and storage), this space comes at a premium cost.

Simply stated, squares are more efficient than circles.

Packaging cost savings = the real driver for change

I love the marketing messaging behind Totino’s packaging change…. “fit more in your freezer,” “fits better in a toaster oven.”

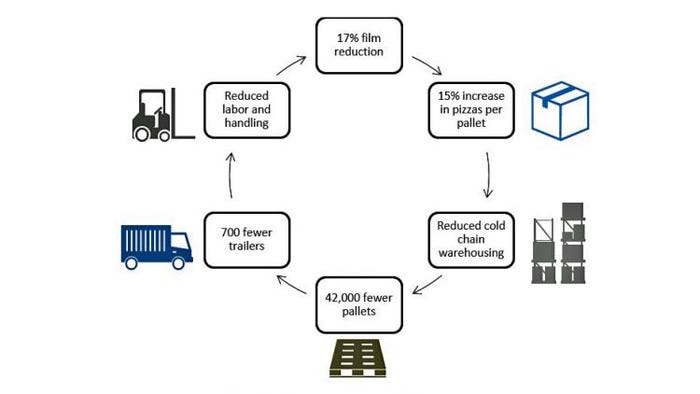

While those may be true, there’s no denying that the change will also drive home some significant packaging and transportation cost savings.

When you start to consider the holistic supply chain impact this change has knowing that the brand sells more than 300 million pizzas annually, the savings really add up.

Although the square is not a very sexy shape, unless you happen to be into boxes, you can bet that logistics and supply chain executives (as well as Huey Lewis) will agree: It’s hip to be square!

Rob Kaszubowski is the Engineering Manager at Chainalytics, where he is focused on reducing product damage and implementing packaging cost reduction initiatives while leading a team of packaging consultants .Rob also contributes to the Packaging Matters blog.

Connect with Rob on LinkedIn and on Twitter @KazPack1

___________________________________________________________________________________

Looking for packaging ideas that can optimize links in your supply chain? Visit MinnPack, September 21-22 in Minneapolis.

___________________________________________________________________________________

About the Author(s)

You May Also Like