What does a packaging engineer do?

A packaging engineer identifies the three common industry activities that characterize the regular duties of a packaging engineer in any supply chain in today’s fast-paced market.

When I first transferred into the packaging program at UW-Stout, I’m pretty sure my friends thought I would be packing boxes for a career. Little did they know that packaging engineers have existed for quite some time, and their roles and responsibilities are often multi-faceted as packaging intersects with so many crucial aspects of an organization.

Whether you’re working with consumer packaged goods companies, food or durable consumer goods, the core principles and activities of a packaging engineer are very similar across the board.

To shed a little light on the subject, here’s a look at the three common activities a packaging engineer actually does:

1) New Product Development (aka, new product introductions)

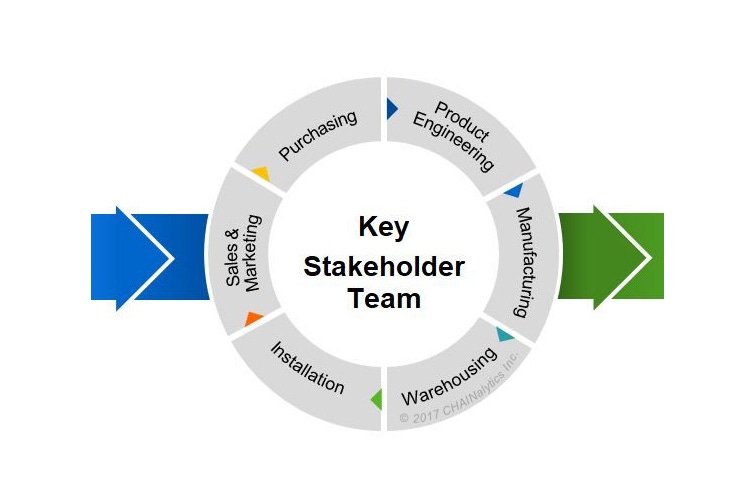

Let’s face it, those new products that marketing wants to launch aren’t going to pack themselves. Packaging teams often collaborate with various stakeholders from cross-functional teams to ensure all key criteria is achieved in the design and performance of the package.

Common activities within this category include:

▪ Project management and communication with packaging materials vendors;

▪ Packaging design and development;

▪ Collaborative reviews with key stakeholders and executive sponsors;

▪ Sustainability metric evaluation;

▪ Distribution testing;

▪ Specification development; and

▪ Product lifecycle management (PLM).

2) Cost Savings Initiatives (aka, value engineering or continuous improvement)

Second to new product launches are the cost take-out initiatives. Some products are rushed into the market before thoroughly evaluating their packaging and supply chain effectiveness, sometimes with excessive packaging to ensure of a successful launch. Once—products have been in the market, opportunity often exists to re-evaluate and value engineer costs out of the package and supply chain system. This can range anywhere from a redesign project to harmonizing common packaging components across multiple SKUs to the creation of compliance standards to integrate at a partnership comprised of multiple organizations.

3) Firefighting and Damage Control

Every job has some level of firefighting. Same goes for packaging engineers. Often these “fires” can be attributed to addressing equipment downtime, jammed packing/ filling/ assembly lines, or last minute communications with vendors or internal stakeholders.

A bigger bucket concerning firefighting often relates to damage reduction. Some of these challenges are driven by executive directives, while others are along the lines of continuous improvement.

Wrapping it all up

Whether you’re in bricks-and-mortar retail, e-commerce or the medical device packaging industry, a packaging engineer plays a major role in your operations. Packaging engineers address a wide variety of issues and opportunities that have a direct impact upon a business’s bottom line. We aren’t simply seeking a better design (although we absolutely love doing that), we’re searching for cost-saving opportunities and sustainability improvements across the entire supply chain.

I know it was easy for my friends to assume my career would be limited to boxes and tape, but each time they rely on the supply chain to deliver a product, I’ve proven just how valuable a packaging engineer can be.

Rob Kaszubowski is Sr. Packaging Consultant at Chainalytics’ Packaging Optimization where he is focused on reducing product damage and implementing packaging cost reduction initiatives. Rob also contributes to the Packaging Matters blog. Connect with Rob on LinkedIn and on Twitter @KazPack1

___________________________________________________________________________________

Constrained by your current production and supply chain options? Assess new connections in packaging and more during MinnPack in Minneapolis November 8-9. It’s part of a comprehensive all-in-one 6-event plastics and advanced manufacturing exhibition. For more information, visit MinnPack.

___________________________________________________________________________________

About the Author(s)

You May Also Like