January 29, 2014

|

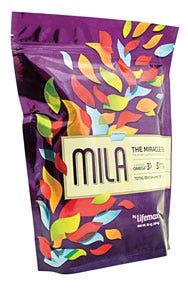

When Lifemax, Inc., Orlando, FL, officially launched its flagship product, Mila™, the direct sales network marketing company also debuted a complete branding strategy that extended from the company's website to vibrantly printed, flexible pouches that contain 16 oz of the health food.

'Miracle' inspiration

A mixture of Salvia Hispanica L. (chia) seed, Mila is processed using a proprietary system that enables the seeds' nutrients to be more easily absorbed by the human body. Lifemax claims that the Mila blend has eight times more Omega 3 than Atlantic wild salmon, six times more calcium than milk and three times more iron than spinach. For this reason, Lifemax has chosen to call its product “the miracle seed,” and the product name was inspired by the Spanish word for miracle—milagros.

Thrice as nice

Lifemax had three top goals for the new packaging: To lower costs so the savings could be passed onto its sales distributors, to reduce the packaging's carbon footprint, and to create a package with high shelf appeal. To help it achieve these goals, Lifemax identified two expert partners. The first partner was creative agency Struck, Inc. (www.struckcreative.com), which already was working with Lifemax on the branding elements for its new website at www.lifemax.net. The second partner was contract packaging company Flex Pack USA, Inc. (www.flexpackusa.com).

High-impact graphics

Flex Pack USA art director Edward McBride led a three-person prepress team, which served as consultant to both Struck's office in Utah and customer company Lifemax, also located in Florida, on the print feasibility of the design. Flex Pack USA also brought in an international partner—sister company Flex Pack Technologies, Pvt. Ltd. (www.flexpackindia.com)—which manufactures and prints the package in India.

Struck provided Flex Pack USA with an Adobe (www.adobe.com) Illustrator file that used several sophisticated effects and a wide range of colors. Effects were created with Illustrator's multiply and transparency filters; these types of graphic design treatments are known to be difficult or impossible to replicate on press. Using a combination of directives and printed samples of the look that Struck was aiming for, Flex Pack USA color separated the files. To achieve the purple gradient used as the pouch's background, Flex Pack USA identified two spot purples that would create the rich effect employed in the design. White ink was used to backward register text. Trapping was done using manual prepress processes, some of which have become a lost art at competing manufacturers. “There's a lot of automated trapping nowadays in prepress,” McBride comments. “Automation and all the workflows nowadays are fantastic, but a little extra work that you can put into it from the ground up I think gives you a little extra and this results in basically a better product in the end.”

|

Final adjustments were made in EskoArtwork's (www.esko.com/artpro) ArtPro application, which was used by the print group in India to engrave the cylinders.

Nothing like the real thing

A two-step proofing process was used to first check the content and other non-color-critical elements via PDF, then all design elements were checked using press proofs. “With a project like this, because it's metallized film and there's surface matte varnishes, there are things that simply cannot be translated in any kind of digital file, when they get that cylinder proof they can actually see the accurate ink on the actual film overlaid on metallized film, they can see where it's going to actually be metallic, they are able to see how that purple is going to look on the metallized film, and they can actually proof that matte varnish,” McBride explains.

Because Flex Pack USA and Lifemax are located near each other, the proofing-and-adjustment process benefited from a hands-on approach. “They [Flex Pack USA] really gave us that added benefit of having a person in front of you; as opposed to trying to do things on the phone, or through pictures and so on,” Lifemax director of information technology Jonathan Ducos remarks. “They held our hands from start to finish designing the bag; they helped us with die lines; they helped us produce prototypes; they gave us samples.”

The resulting two-side print pouch was reverse- and surface-printed using nine inks, which includes process, Pantone Matching System spot color and white inks, laid down by a ExperPAC 3000 press from Expert Industries (www.expertindia.in). The 10-color rotogravure press images up to 300 meters/min and also auto-registers web material from 1 to 1.3 meters.

Paying the savings forward

The standup pouches were converted using a Model TSZ-500 pouch maker from Speedway Machines Pvt. Ltd., (www.speedwaymachines.com). Material slitting and rewinding was done on a machine from SP Ultraflex Systems Pvt. Ltd., (www.spultraflex.com). The new custom-made pouches were less expensive than the stock plastic canister Lifemax used to prelaunch the product. Yet, the pouch still offers protection against light and moisture damage.

The health food company passed on the lowered cost of packaging to both its distributors and customers by increasing the package size from 12 to 16 oz while lowering the price. The new package has a suggested retail of $55, and the bigger serving size is a typical month supply for an adult. The pouches also have a lower carbon footprint, therefore a lower cost to the environment.

Naturally conservative

|

|

Flex Pack USA has four different dedicated production lines, one of which is a certified organic line in a separate area. In sugar filling and packing alone, the 26,000-sq-ft facility will often copack up to 300,000 lbs of product/day. Its experience in sugars has helped the copacker optimize its operation for working with natural materials with minimal loss of product.

For example, the company uses a vacuum system installed by Southland Conveying Solutions (www.southlandconveyingsolutions.com) to transport sugar. This provides benefits over a screw-feeding system that can crystallize the sugar, causing multiple bottlenecks and frequent cleanups, and most importantly loss of materials. “There are enough different types of sugars in the marketplace that you can learn a lot about any potential product,” Flex Pack USA vp of operations Ken Dorey explains. He drew upon his experience packing 6X powdered sugar to quickly come up with copacking strategy for the light and fluffy seed.

Chia seed is received in 100-lb bags, which are fed into hoppers bolted onto a Cogan (www.ecogan.com) mezzanine. The seed is screened by a No. 2 stainless-steel mesh, and rare earth magnets prevent metal from entering the A-100 filler from AMS Filling Systems, Inc. (www.amsfilling.com).

Accustar checkweighers from Thermo Fisher Scientific, Inc. (www.thermofisher.com) use a pulse feedback system to verify pouch weights. Operators then insert a serving scoop into each pouch before it is sealed by a custom-built, hot-air sealer. An A100 ink-jet printer, manufactured by Domino Amjet, Inc. (www.dominoamjet.com) and installed by Alles (www.allesinc.com), codes the bags before they are hand-packed into cases.

Easing into the future

With its new branding and packaging in place, Lifemax is working on attracting more people to its product and its sales network. The company is upgrading the back-end of its website—which already allows a visitor to either set up recurring delivery schedules for Mila or become a distributor—to become a very robust business management system for its distributors. Lifemax also plans to introduce a 4-oz package that will allow users to easily share a week's worth of seed with friends and family.

More information is available: |

Flex Pack USA, Inc., 407/857-2883. www.flexpackusa.com. |

Adobe Systems, Inc., 800/833-6687. www.adobe.com |

Alles, 800/327-5130. www.allesinc.com |

AMS Filling Systems, Inc., 610/942-4200. www.amsfilling.com. |

Cogan USA, Inc., 800/567-2642. www.ecogan.com/ |

Domino Amjet, Inc., 847/244-2501. www.dominoamjet.com. |

EskoArtwork, 937/454-1721. www.esko.com. |

Expert Industries, 91-80-783-2690. www.expertindia.in |

Flex Pack Technologies, Pvt. Ltd., 01284-264448. www.flexpackindia.com. |

Southland Conveying Solutions, 770/483-2193. www.southlandconveyingsolutions.com. |

Speedway Machines Pvt. Ltd., 91-11-259-1-8854 www.speedwaymachines.com |

SP Ultraflex Systems Pvt. Ltd., 91-22-284-5-4410. www.spultraflex.com. |

Struck, Inc., 801/531-0122. www.struckcreative.com. |

Thermo Fisher Scientific, Inc., 800/678-5599. www.thermofisher.com. |

About the Author(s)

You May Also Like