Medical Device Maker’s Stewardship Goals Prioritize Packaging

Medtronic’s recently released ESG report ups the ante for reducing, reusing, and recycling eligible plastic packaging.

Medtronic is no stranger to receiving industry accolades for its sustainable packaging innovations. And if this year’s Environmental, Social and Governance (ESG) report is any indication, that trend is set to continue in 2024.

The medical device company has set practical yet ambitious sustainability targets in 2023 that address the growing problem of plastic pollution and associated greenhouse gas (GHG) emissions. The end goal: to shrink packaging volume for current products and incorporate waste-reducing design practices into new product development practices.

Medtronic’s five new product stewardship targets in FY23 — set for achievement by FY30 — are as follows:

• Publish partial life-cycle assessments (LCAs) for 100% of products and additionally publish full LCAs for 50% of products.

• Convert 50% of eligible product codes to electronic instructions for use (IFU) within applicable regions.

• Integrate circularity and eco-design criteria into the new product development process.

• Achieve one of the following qualities for 95% of eligible plastic packaging: is industrially recyclable, contains post-industrial recycled content, or demonstrates optimized design (by volume, weight, or thickness).

• Reduce packaging for 20 additional high-volume products for a total of 50% reduction against the FY21 baseline.

Sustainable by design.

To minimize waste and extend product lifecycles, Medtronic looks for ways to optimize how products are designed, built, used, reused, recycled, and disposed of — and packaging is an integral part of these pursuits. As far back as 1998, for instance, PKG Packaging was providing Medtronic with biodegradable and compostable packaging solutions for insulin pumps used by patients with diabetes.

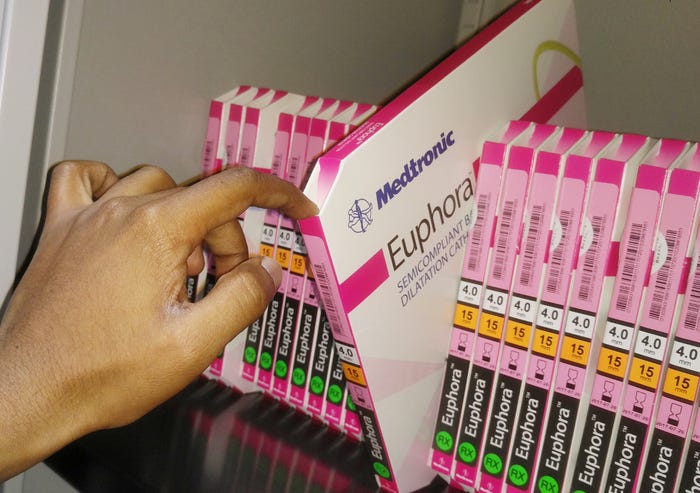

In 2018, the company won an Institute of Packaging Professionals (IoPP) AmeriStar Award for the innovative packaging design of its Euphora balloon angioplasty devices featuring upgrades to the carton and internal configuration (below). In addition to simplifying removal from the shelf and device preparation, the new design allowed for an increased number of units per pallet and a reduction of CO2 emissions.

Medtronic

Then, in 2021, Medtronic received another AmeriStar Award — this time for a packaging redesign of its RFA ClosureFast device in partnership with Oliver Healthcare Packaging. The company implemented a card/hoop design to secure the venous cauterization device, resulting in significant material and transportation savings. Pouches were reduced by 11%, shipping cases were reduced by 33%, and cartons were reduced by 45%. The carton holding the pouched device used recycled clay-coated newsback (CCNB) material and eliminated the use of bleached pulp. These modifications reduced solid waste by 60% for every 500,000 devices sold while smaller packaging allowed more devices per pallet, resulting in fewer sterilization cycles and fewer truckloads.

Continuing its trend of reducing packaging materials, the company successfully shrank the sterile packaging volume of its spinal cord stimulation needles in FY21, reducing GHG emissions related to the product. And more recently, in FY23, Medtronic introduced customizations for Attesta pacemakers that reduced the volume of packaging with each device. Previously, the device was packaged with compact disc and paper instructions in multiple languages. Now, IFUs are added at local distribution centers and provide only the relevant language and format for the region, saving five tons of plastic and 20 tons of paper annually.

A mission to reduce emissions.

Reducing packaging and GHG emissions go hand in hand. According to its ESG Report, Medtronic is on track to meet its goal of 50% GHG emissions reduction by FY25. The company also has a goal of becoming carbon neutral in its operations by FY30 and reducing carbon emissions to net zero in its operations, supply chain, and logistics by FY45.

Steps to achieve carbon neutrality in its operations include continuing to reduce energy use by increasing efficiency, increasing the use of clean energy through onsite renewable and alternative generation, and investing in more renewable energy credits and carbon offsets.

For more information, read Medtronic’s full 2023 Sustainability Report.

About the Author(s)

You May Also Like