Top news in November looks to the future of packaging

Smart packaging predictions, Amazon’s new ecommerce packaging program with wide-reaching effects, and significant innovations galore starred last month with packaging professionals around the globe. The articles posted on PackagingDigest.com in November 2018 that were the best read are presented here again, in reverse order based on the total number of views:

5. Amazon incentivizes brands to create frustration-free packaging

It’s nearly three months since the news broke that Amazon is asking its vendors to design packaging specifically for ecommerce distribution. We’re still getting the word out to the international packaging community, though, which explains how an article that was posted on Sept. 18 shows up in the top article list for November.

To help reduce packaging waste and improve efficiency of ecommerce shipping for its vendors, Amazon will require that select products being sold and fulfilled by Amazon arrive in its fulfillment centers in certified packaging under its Frustration-Free Packaging (FFP) program. This means that the product does not need to be prepped for shipping (such as being enclosed in a zipper baggie to contain possible leaks) or put into an overbox.

Companies complying before the deadlines (Aug. 1, 2019, for the U.S. and Canada; Oct. 1, 2019, for six European countries) will receive a one-time $1 credit for each product properly packaged. After those dates, companies will be charged a $1.99 fee for each product/package not certified.

Brent Nelson, Amazon’s senior manager, packaging – sustainability, answered about two dozen questions about the new Frustration-Free Packaging Vendor Incentive Program in a free Packaging Digest webinar, which you can view on-demand by clicking here.

We’ll continue to cover any new developments. In the meantime, we’d love to hear what you think about the program. Take our short survey now, which most people complete in about three minutes. Access the survey here.

NEXT: Japan’s Kao Group makes sustainability look raku raku (‘so easy’)

4. Japan’s Kao Group makes sustainability look raku raku (‘so easy’)

In an exclusive interview with Packaging Digest, Michitaka Sawada, president/CEO of Kao Corp., tells us about the company’s sustainability philosophy, efforts and results.

Refillable packaging is among the successes this year, with all the company’s viscous products packaged in refills. Its BLP (bottle-like pouch) refills, which are designed for outstanding ease of use, are known in Japanese as raku raku eco pack, with raku raku meaning “so easy.” With the refill pouch, Kao has cut the amount of plastic waste from Kao personal care and household products sold in Japan by 74%.

These refills combine with the new Smart Holder, which enables the film-based pouches to be used as the primary product package.

NEXT: 3 ‘smart packaging’ predictions for 2019

3. 3 ‘smart packaging’ predictions for 2019

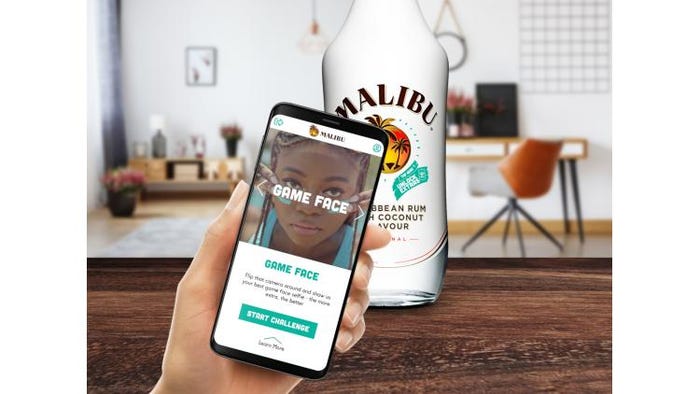

Cameron Worth, founder of SharpEnd—a London-based branding agency that specializes in using the Internet of Things (IoT) to connect with consumers—introduces and explains three new areas of smart packaging in the coming year:

Prediction #1: More than 10 million fast-moving consumer goods (FMCG) will be interacted with throughout 2019. And near-field communication (NFC) applications for consumer engagement will explode once the new range of iPhones become mass-scale devices.

Prediction #2. Brands are beginning to “in house” their innovation capabilities and laboratory programs.

Prediction #3. Agencies will begin to offer “IoT / Voice” consulting practices to capitalize on the growing interest.

Read the full article (by clicking on the headline link above) to find out what these predictions might mean to you and your packaging department.

NEXT: Packaging innovation awards celebrate excellence

2. Packaging innovation awards celebrate excellence

Excellence in any endeavor takes effort, commitment and passion. Here are 18 examples of packaging superiority in a fast-reading photo gallery, which presents winners of Dow Chemical Co.’s 2018 30th Awards for Packaging Innovation competition in three of the four tiers: the Diamond Award (best of the best); Diamond Award finalists; and Gold Awards recipients. Not shown are the 11 Silver Award winners, but we do include a link to them.

We start with the Diamond Award, given to Procter & Gamble for its Air Assist technology. A flexible pouch is made more rigid—adding to the package’s functionality—by selectively inflating areas to add stiffness to the multiple layers of film.

P&G won two other awards this year, too. Other companies recognized in our gallery are Amcor Rigid Plastics, The Coca-Cola Co., Ecologic Brands Inc., Delivering Happiness Ltd. (aka Garçon Wines), PumpArt System, Rieke, Sealed Air, Uflex Ltd., CleanCut Technologies, Kanebo Cosmetics Inc., PepsiCo/Frito-Lay, PepsiCo Mexico Foods and ProAmpac, Sonoco Products Co., GSK and Wave Intl.

NEXT: Pack Expo 2018: 8 advancements in food and beverage packaging

1. Pack Expo 2018: 8 advancements in food and beverage packaging

Food and beverage represent the largest consumption markets of packaging. So it’s no surprise that any report about packaging innovation in this area gets attention from the packaging community, even from other quarters because new technologies often start here and then crossover into other product categories.

This octet of innovations seen at the recent packaging trade show is just a taste of what senior technical editor Rick Lingle unpacked while walking the 1.25 million net square feet of McCormick Place and talking with as many of the 2,500 exhibitors as time allowed.

Click the headline above to read more details about any of these developments:

1. A barrier tray looks and feels like kraft paper, with the distinct advantage that it can be molded into packages that are recyclable.

2. An NFC tag is sealed and protected inside a polypropylene cap by the plastic liner, so brand owners can incorporate connectivity via their package without slowing down bottling line speeds with a secondary NFC-tag labeling operation.

3. Laminated holographic cartons—made from rollstock—can also be foil stamped and embossed, gaining consumers’ attention on shelf.

4. New and patented flexible valve technology provides controlled dispensing and spill-proof containment of liquids in flexible packaging. The discrete flexible valve yields when pressure is applied to the product compartment, enabling controlled dispensing. When squeeze-pressure is released, the valve reoccupies and closes the dispensing channel.

5. New Elite modified-atmosphere packaging (MAP) PET trays for fresh protein products (meats and poultry) use up to 95% post-consumer recycled content, are 100% recyclable into other plastic items and offer high-clarity—just 5% haze.

6. The Dromo PET bottle—engineered specifically for liquid or semi-viscous products sold through ecommerce channels—is a packaging concept similar to the Kao Smart Holder you read about in #4 of this November top-articles list. A reusable cartridge holds the lightweight Dromo bottles—a 16-ounce bottle weighs 9.6 grams versus an industry standard 39 grams—which have opposing flat-side panels that provide sidewall strength and facilitate stacking during shipping.

7. Designed to address consumer frustrations with opening protein powder packaging and other larger size canisters of granulated and powdered products, the 120mm BAP (Bonded Aluminum to Plastics) Olympian Closure has convenient pull-ring removal and an attached or separate overcap. Benefits include built-in tamper-evidence and tool-less easy opening for large containers.

8. The lowly bread bag reclose tag evolves into a mini branded billboard with new custom-printed products, providing branding and promotional opportunities of otherwise common closures for bagged baked goods, produce, confections and more.

9. Surprise! Always going the extra step for you, Lingle adds a bonus item with two dramatic examples of corrugated packaging creativity.

Enjoy!

********************************************************************************

In addition to leading suppliers showing the latest solutions in labeling, automation, food packaging, package design and more—WestPack 2019 (Feb. 5-7; Anaheim, CA) gives you access to the industry's leading educational offerings with the 3D Printing and Smart Manufacturing Innovations Summits, the MD&M Medtech Conference and free industry education at the Expo. Register to attend today!

About the Author(s)

You May Also Like